13

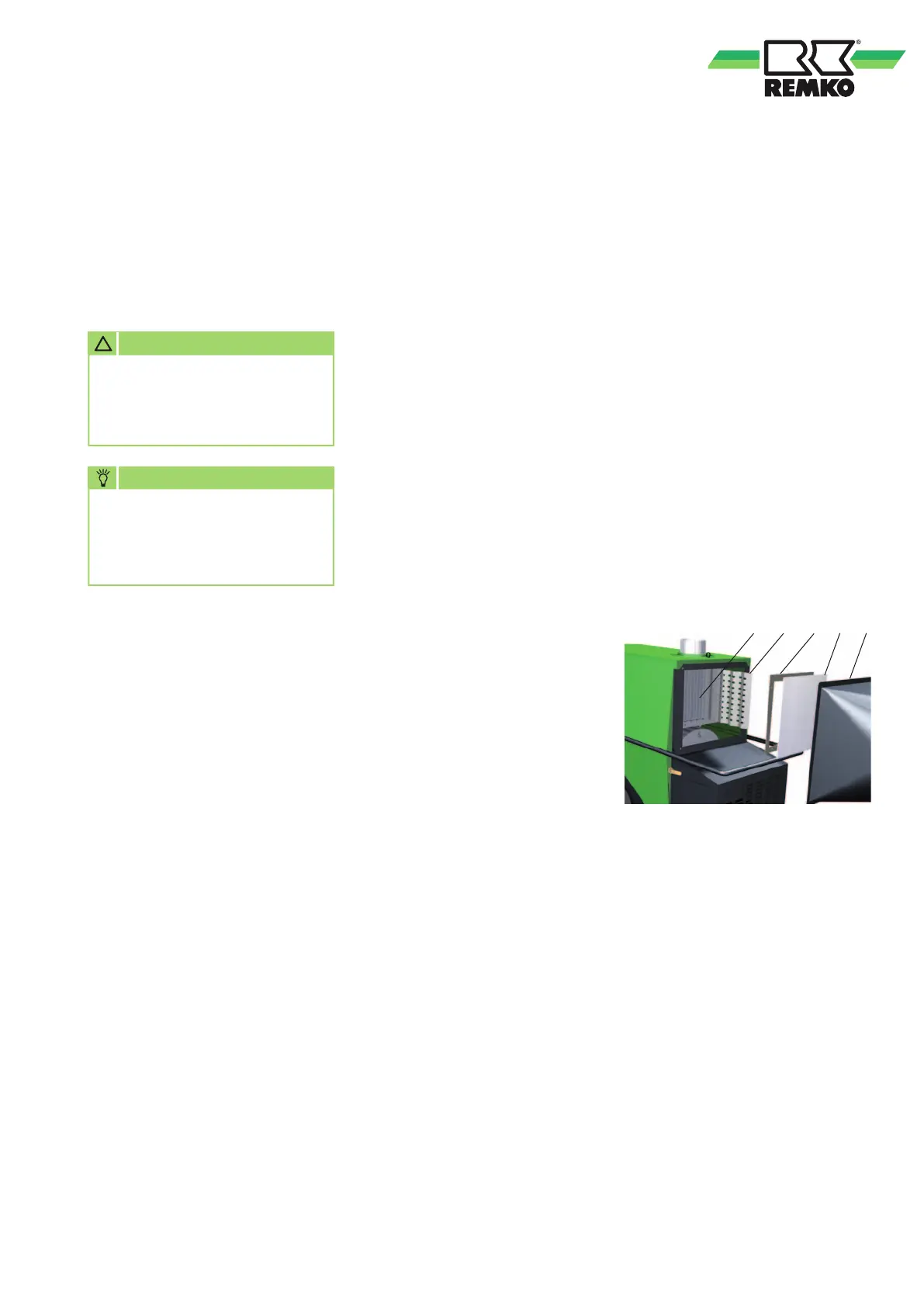

Cleaning the heat exchanger

1. Set the operating switch to the

"0" position and remove the

power plug from the mains

socket.

2. Take off the exhaust hood 1

after removing the 4 fastening

screws. Hot air hoses present

need not necessarily be

removed.

3. Remove the inspection cover 2

and withdraw the exhaust gas

suppressors 4.

4.

Clean the flues 5.

A special cleaning brush is

available as an accessory with

EDP no. 1103110.

5. Clean the exhaust gas

suppressors or replace damaged

exhaust gas suppressors.

6. Check the seal 3 for the

inspection cover and replace

any damaged seals.

7. Following maintenance work,

refit all parts carefully in reverse

order.

Please also observe the

instructions on the next page.

Regular care and observation of

some basic requirements, once

yearly or after extended times at

a standstill, will ensure trouble-free

operation and a long service life of

the units.

■

Keep the units free of dust and

other deposits

■

Only clean the units with a dry

or moistened cloth

■

Never subject to direct jets of

water

e.g. pressure washers etc.

■

Never use abrasive or solvent-

based cleaners

■

Use only suitable cleaners, even

for heavy contamination

■

Use only clean EL heating oil or

diesel fuel

Beware of paraffin formation!

■

Check the fuel filter(s) for

contamination at regular

intervals. Replace contaminated

filter if necessary

■

Check the units for mechanical

damage and have defective

parts properly replaced

■

Check the fan blades and

combustion chamber with heat

exchanger for contamination at

regular intervals and clean these

if necessary

■

Check the on-site oil tank

regularly for contamination,

condensate water, foreign

bodies and clean if necessary

Care and maintenance

s

s

s

4 3 2

1

5

■

Check that the safety devices

are operating correctly at

regular intervals

■

Keep the probes for the safety

devices free of dust and dirt

■

Have the exhaust gas values for

the forced-air burners checked

by authorised specialists at

regular intervals.

For safety reasons we

recommend the conclusion of a

maintenance contract

■

Observe maintenance and care

intervals

■

In the event of defects that

endanger the operational safety

of the units, operation of the

units must be discontinued

immediately and the supervisor

informed!

Cleaning tasks

The units, including the heat

exchanger, combustion chamber

and forced-air burner must be

cleared of dust and dirt after

every heating period, or possibly

earlier depending on the operating

conditions.

Wearing parts, such as exhaust

gas suppressors, seals, oil filter

inserts and oil nozzles for example,

should be checked and replaced if

necessary.

NOTE

Adjustment and maintenance

work may only be carried out

by authorised and qualified

technicians.

CAUTION

Before undertaking any work

on the units, the power plug

must be removed from the

mains socket.

!

Loading...

Loading...