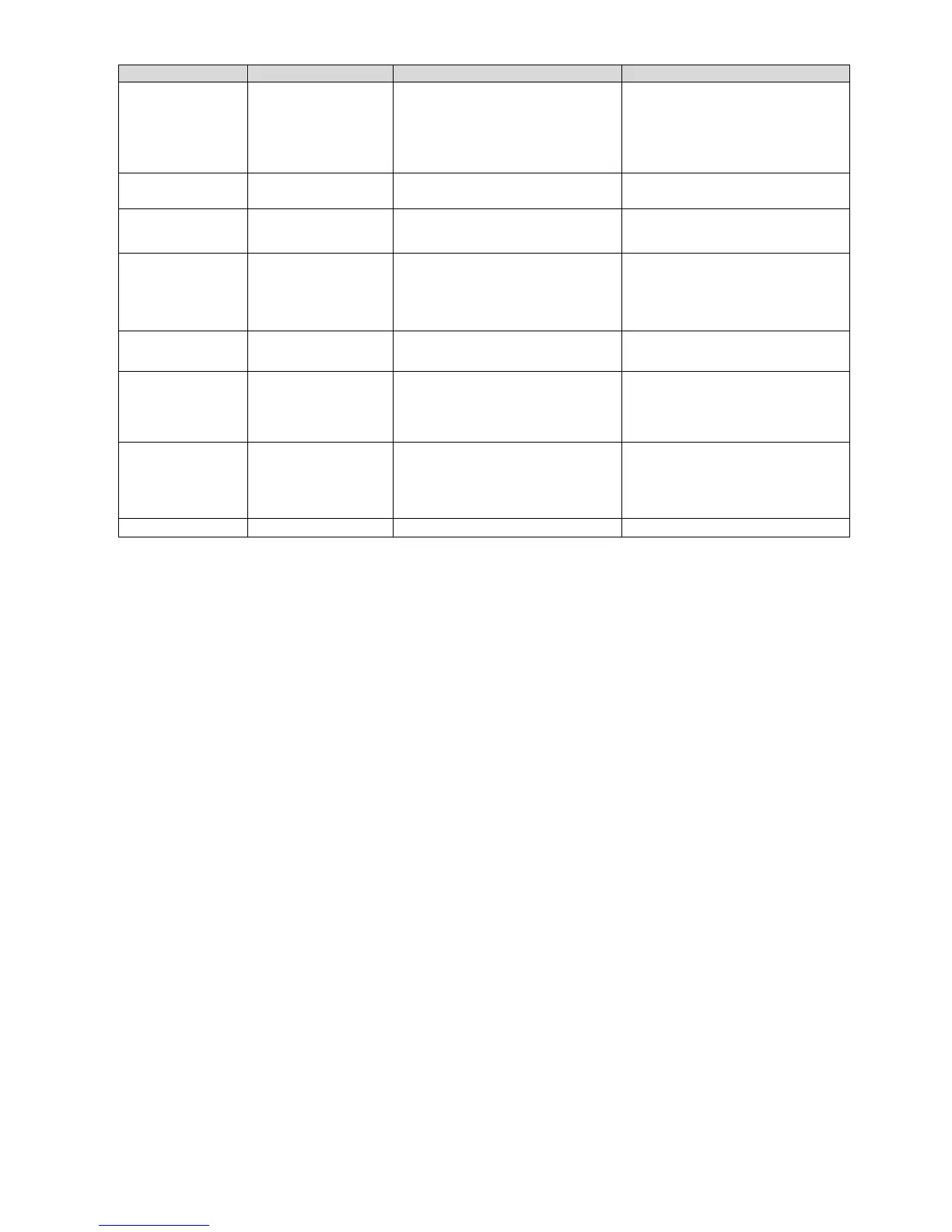

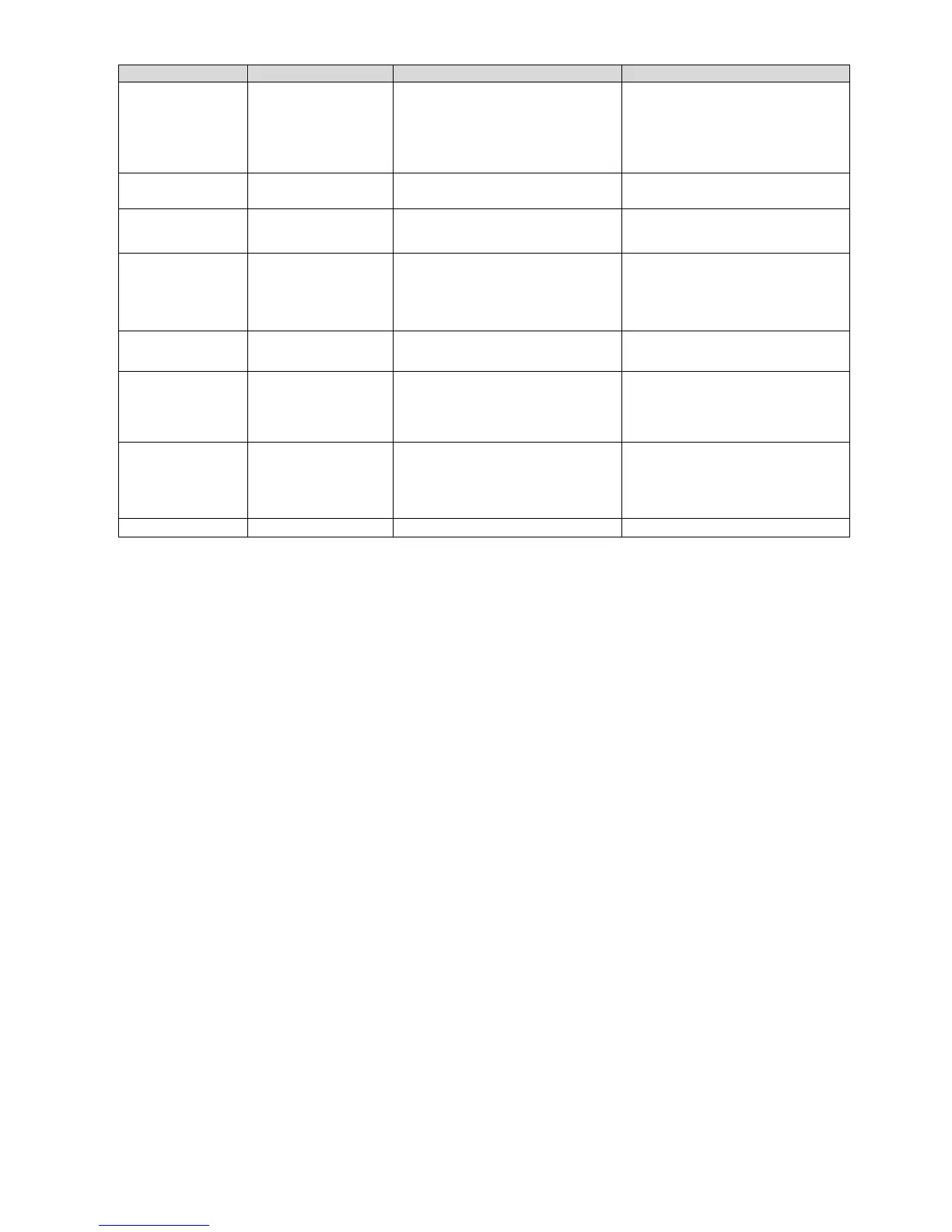

• coil power is too high

• frequency is set too low

• coil air-gap is too large

• short-circuit

• use a controller with a higher

current rating

• increase frequency

• reduce air-gap

• check wiring and coil

• short-circuit on output

• coil faulty

• selected frequency too low

• selected Amplitude too high

• increase frequency

• decrease amplitude

• supply voltage too high

• back EMF from drive coil

(possible at lower frequen-

cies)

• check mains voltage

• control unit may have to be

changed for another type –

contact manufacturer

• defective sensor

• wrong sensor wiring

• test sensor

• check wiring

External tempera-

ture switch

• external temperature switch

has reached his maximum

• no temperature switch con-

nected

• check magnet temperature

• bypass the magnet tempera-

ture input

Track control sensor

time-out exceeded

• sensor time-out is activated

but not required

• sensor has detected no pro-

duct

• switch-off sensor time-out

• check mechanical system

If the above procedures do not solve the problem and it appears that the unit is faulty then please use the

check sheet provided before returning the controller to your supplier.

21

Loading...

Loading...