Cleaning, wear and service

49

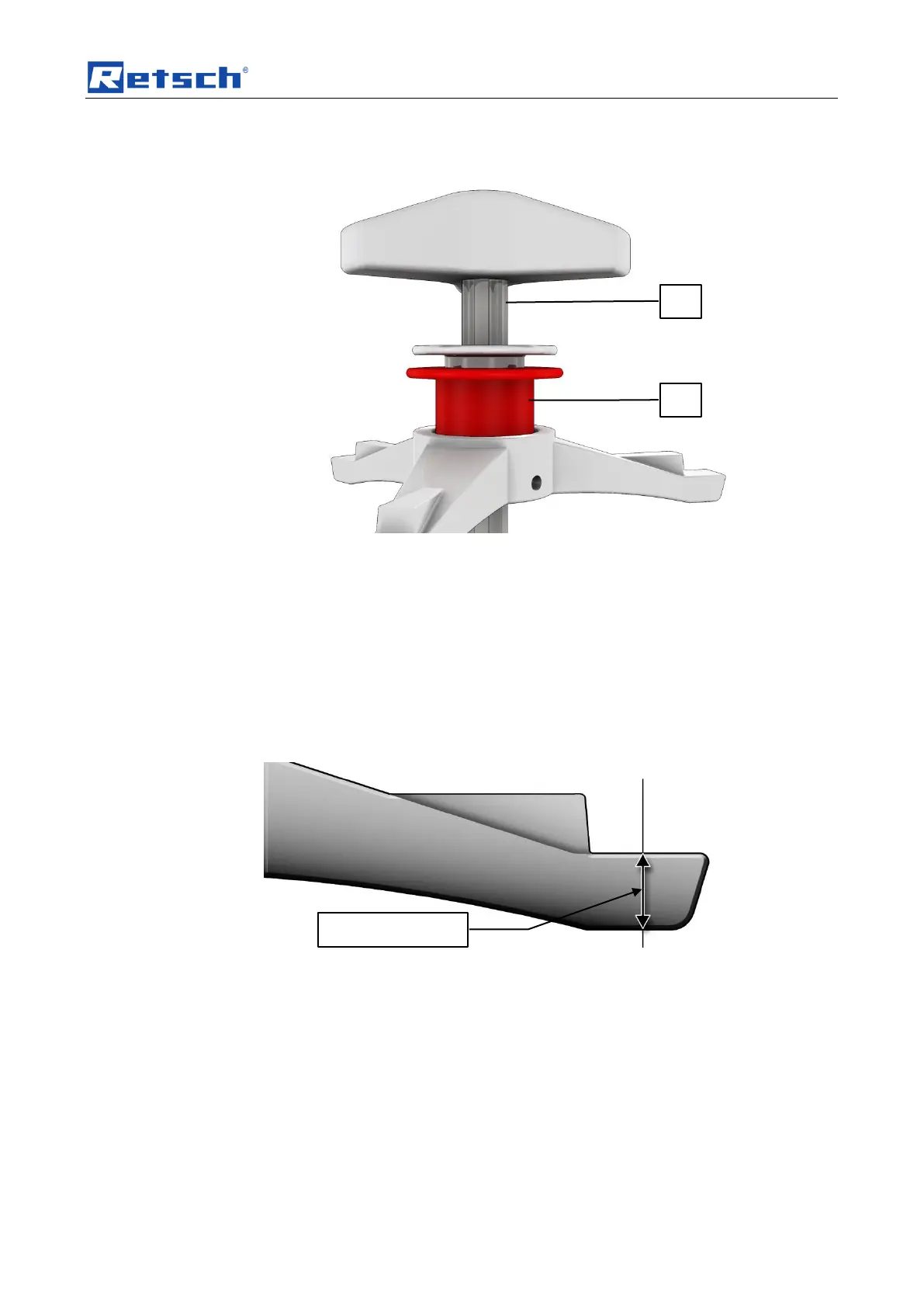

8.1.1 Servicing the clamping unit

Fig.

: Servicing the clamping unit

• Check that the threaded spindle (Gs) and locking sleeve (N1) can move

freely.

– In most cases a drop of oil will help.

The smooth running of the threaded spindle and locking sleeve is the prerequisite

for the secure clamping of the grinding jars.

Locking sleeves which do not slide down automatically through spring force cannot

reliably prevent the threaded spindle from coming loose. The grinding jars may be

ejected.

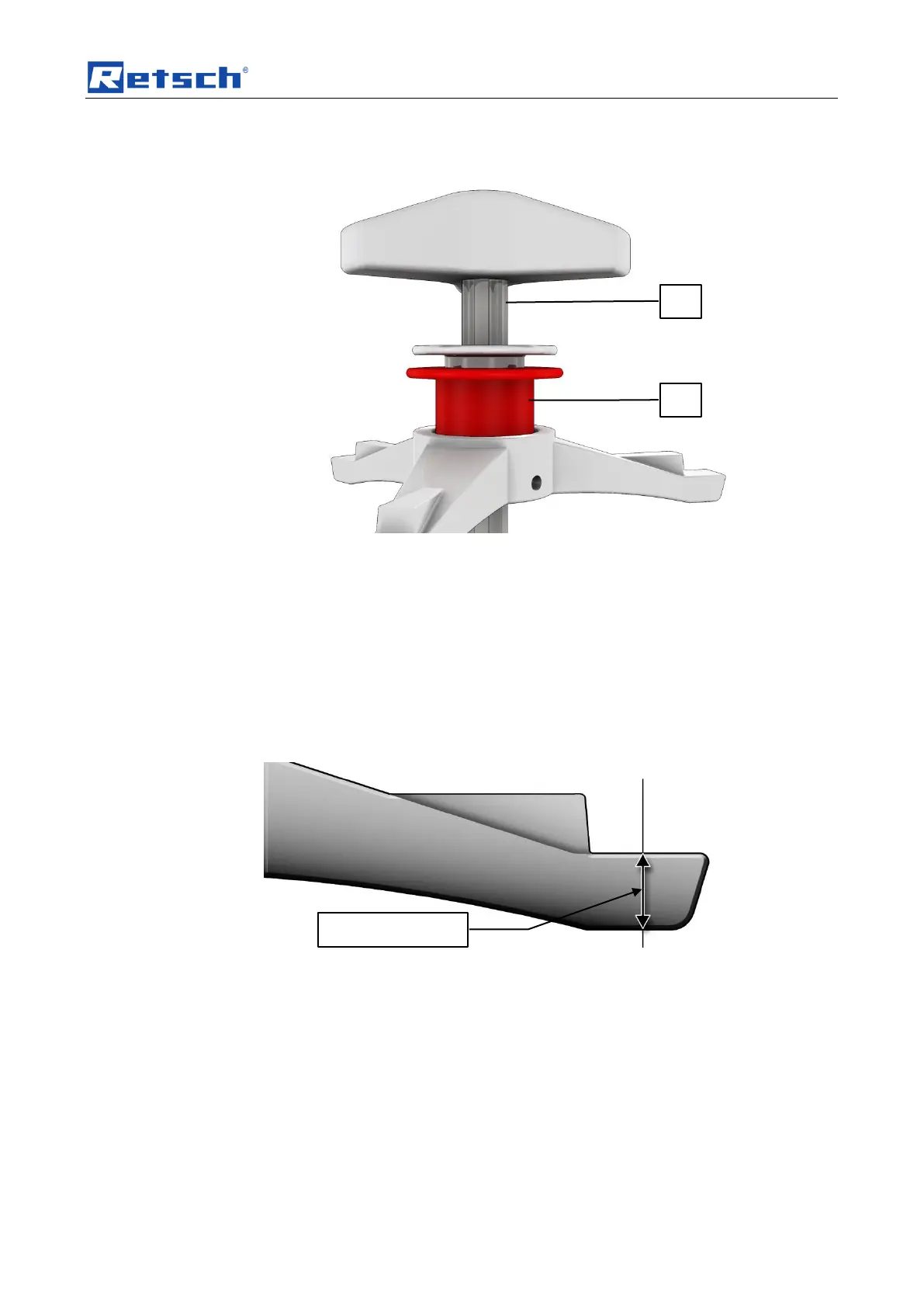

8.1.2 Wear to the bases of the clamping unit

Fig.

: Wear to the bases of the clamping unit

• Check the thickness (D1) of the three lead frame bases regularly for wear (at

least monthly).

– The thickness (D1) of the three lead frame bases must not be less than

7mm.

– Operational safety can no longer be guaranteed if the thickness falls below

this value (D1). The grinding jars may be ejected.

Loading...

Loading...