Do you have a question about the Rexroth Indramat BZM 01.3-01-07 and is the answer not in the manual?

Guidelines for the intended and correct use of Rexroth Indramat products.

Description of typical applications and areas where drive controllers are designed to be used.

Definition and examples of inappropriate use of drive controllers outside specified conditions.

Instructions to eliminate risks of bodily harm or material damage before equipment startup.

Identification of hazards associated with improper use, such as electric shock and dangerous movements.

Safety measures for preventing contact with live electrical parts and high voltages.

Guidelines for connecting equipment to terminals with voltages between 0 and 50 Volts.

Precautions against dangerous movements caused by faulty motor control or wiring.

Health hazard information for persons with pacemakers, implants, or hearing aids near electrical equipment.

Safety precautions regarding hot housing surfaces and the need to wait for cooling.

Safety instructions for handling and mounting parts and components to prevent injuries.

Detailed technical specifications including dimensions, electrical data, and environmental conditions.

Detailed electrical specifications for mains connections and power sections of DKC components.

Graphs illustrating allowed DC bus continuous power without auxiliary components.

Information on how CZM01.3 affects allowed DC bus continuous power.

Details on the impact of CZM01.3 and GLD12 on DC bus continuous power.

Detailed information on electrical connections independent of drive controller type.

Detailed information on the X1 connector for control voltage supply and connections.

Technical description and connection details for the serial interface (RS232).

Technical description and connection details for digital and analog inputs/outputs.

Technical description and connection details for Encoder 1.

Technical description of connectors for DC bus, motor, and mains connections.

Technical specifications including dimensions, materials, ambient conditions, and electrical data.

Detailed electrical data for mains connections and power sections of DKC**.3-016 components.

Overview of mains supply options: Single source and Group supply.

Diagram showing allowed peak power in the DC bus for DKC**.3-016-7-FW.

Diagrams showing allowed DC bus continuous power with single-phase mains connection.

Detailed information on electrical connections for DKC**.3-016.

Identification of connectors on the DKC**.3-016 front view.

Comprehensive wiring diagram showing all connections for DKC**.3-016 drive controllers.

Description of AH and RF input functions for drive control for DKC**.3-016.

Guidelines for connecting the motor for DKC**.3-016.

Technical description of connectors for motor temperature monitoring and holding brakes.

Information on connecting and loadability of the holding brake.

Technical specifications including dimensions, materials, ambient conditions, and electrical data.

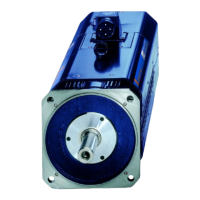

Detailed electrical data for the BZM01.3 power section.

Detailed information on electrical connections for the BZM01.3 module.

Comprehensive terminal diagram for the BZM01.3 module.

Information on single-phase and three-phase mains connections.

Technical specifications including dimensions, materials, ambient conditions, and electrical data.

Mechanical dimensions for the CZM01.3 auxiliary capacitance module.

Specifies ambient and operating conditions for the CZM01.3.

Detailed electrical data for the CZM01.3 power section.

Detailed information on electrical connections for the CZM01.3 module.

Technical specifications including output voltage, current, input voltage, and degree of protection.

General requirement for permanent connection of ECODRIVE03 drive controllers to the power supply network.

Explanation of control circuits for mains connection, including Bb contact and switching states.

Guidelines for using the E-stop function for drive-internal error reactions.

Information on the internal DC bus dynamic brake (ZKS) and its applications.

Selection guidelines for mains contactors and fuses, including current calculations.

Selection table for Q1 fuses and K1 contactors, including current and cross-section data.

Considerations for control cabinet planning, including mechanical and thermal data.

Explanation of how power dissipation is determined by current load and regenerated power.

Guidelines for mounting position and required distances for ventilation and heat dissipation.

Example of arranging components in multiple rows within a control cabinet considering airflow.

Guidelines for using cooling units, including handling condensation.

Explanation of how drive components are labeled with type designations and labels.

General guidance for problem search using diagnostic display and handling defective units.

Step-by-step procedure for replacing the drive controller, including safety precautions.

Procedure for replacing the motor, including safety and reference re-establishment.

Safety precautions and guidelines for replacing cables.

Detailed instructions for replacing firmware and parameter modules.

Step-by-step instructions for replacing the firmware module.

Instructions for replacing the entire programming module.

Specific instructions for replacing firmware on DKC**.3-016-7-FW.

Conditions relevant to supply and regeneration when sizing the drive.

Formulas for calculating allowed power and energy on the device side.

Formulas for calculating power and energy resulting on the installation side.

Formulas and diagrams for calculating allowed continuous braking resistor and DC bus power.

Recommendations for control cabinet construction regarding EMC and cooling.

Guidelines for wire routing and wiring of drive controllers.

List of required measuring equipment, PC hardware/software, and link cables for system startup.

Recommended switching on sequence for DKC**.3 drive controllers.

Recommended shutdown sequence diagram and timing parameters.

Contact information for Rexroth's service helpdesk.

| Brand | Rexroth Indramat |

|---|---|

| Model | BZM 01.3-01-07 |

| Category | Controller |

| Language | English |