15-8 Control Communication - Field Busses and Protocols Rexroth IndraDrive FCS01.1

DOK-INDRV*--FCS01*****-IB01_EN-P

Profibus Telegram Structure

PCD Useful Data Section (PCD)

In process data section PCD, control words and command values are

transmitted from the master to the converter, and status words and actual

values are sent from the converter to the master. The structure of the

PCD section is always identical in the sequence of its elements (words),

but is designated in different ways depending on the direction of data flow

master ⇒ converter / converter ⇒ master.

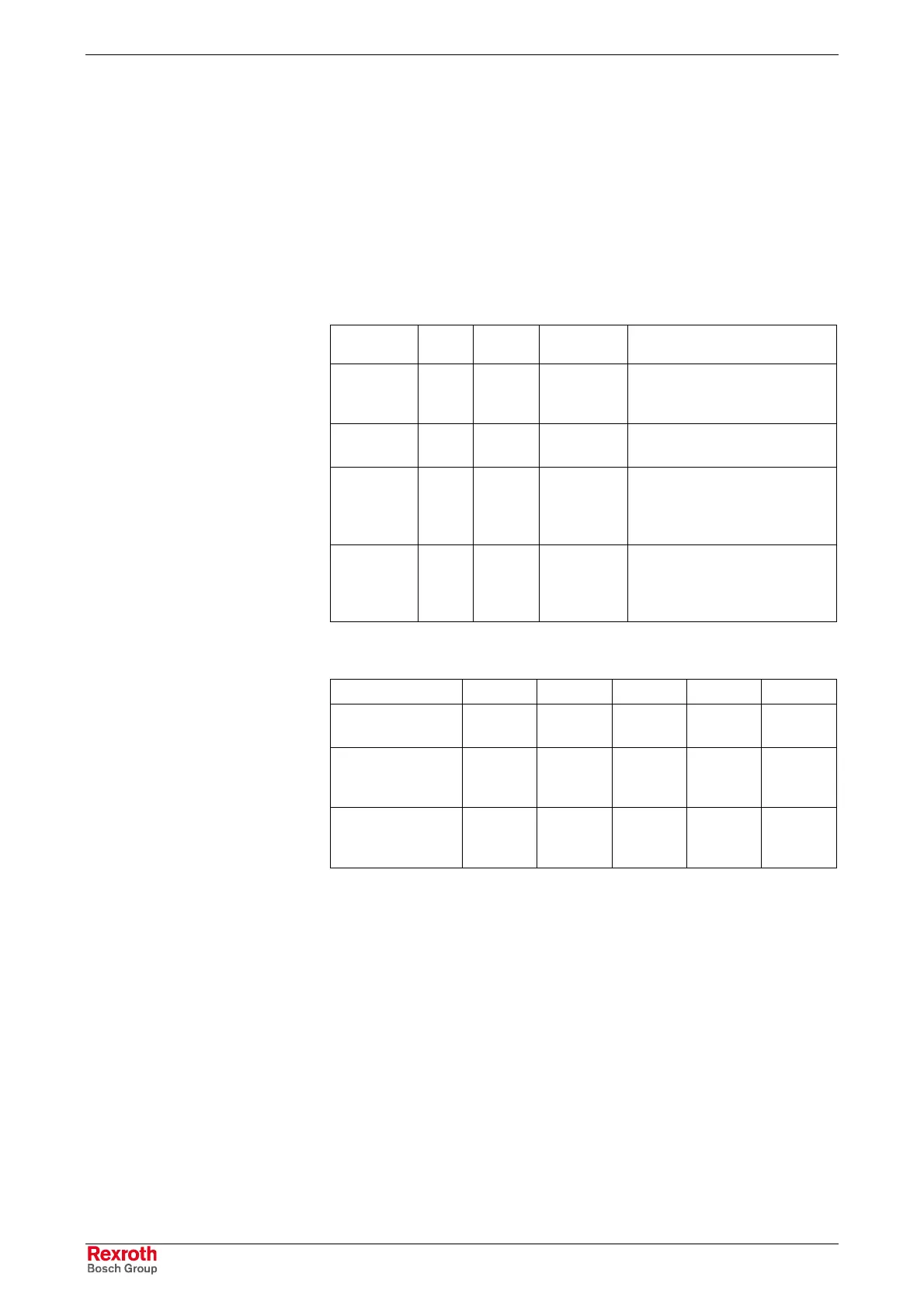

The structure of the process data section of the useful data is as follows:

Payload Abbr. Length

[bit]

Significance Contents

Control

word

CTW 16 Job

telegram

contains control bits (e.g.

release, quick-stop, error

confirmation)

Status

word

STW 16 Response

telegram

contains status bits (e.g. FC

is running, error)

Command

values

(max. 3

available)

CV1..3 16 or 32 Job

telegram

e.g. frequence setpoint,

position setpoint, torque

setpoint

Actual

values

(max. 3

available)

AV1..3 16 or 32 Response

telegram

e.g. actual frequency value,

actual position value, actual

torque value

Fig. 15-10: Process data section of the useful data

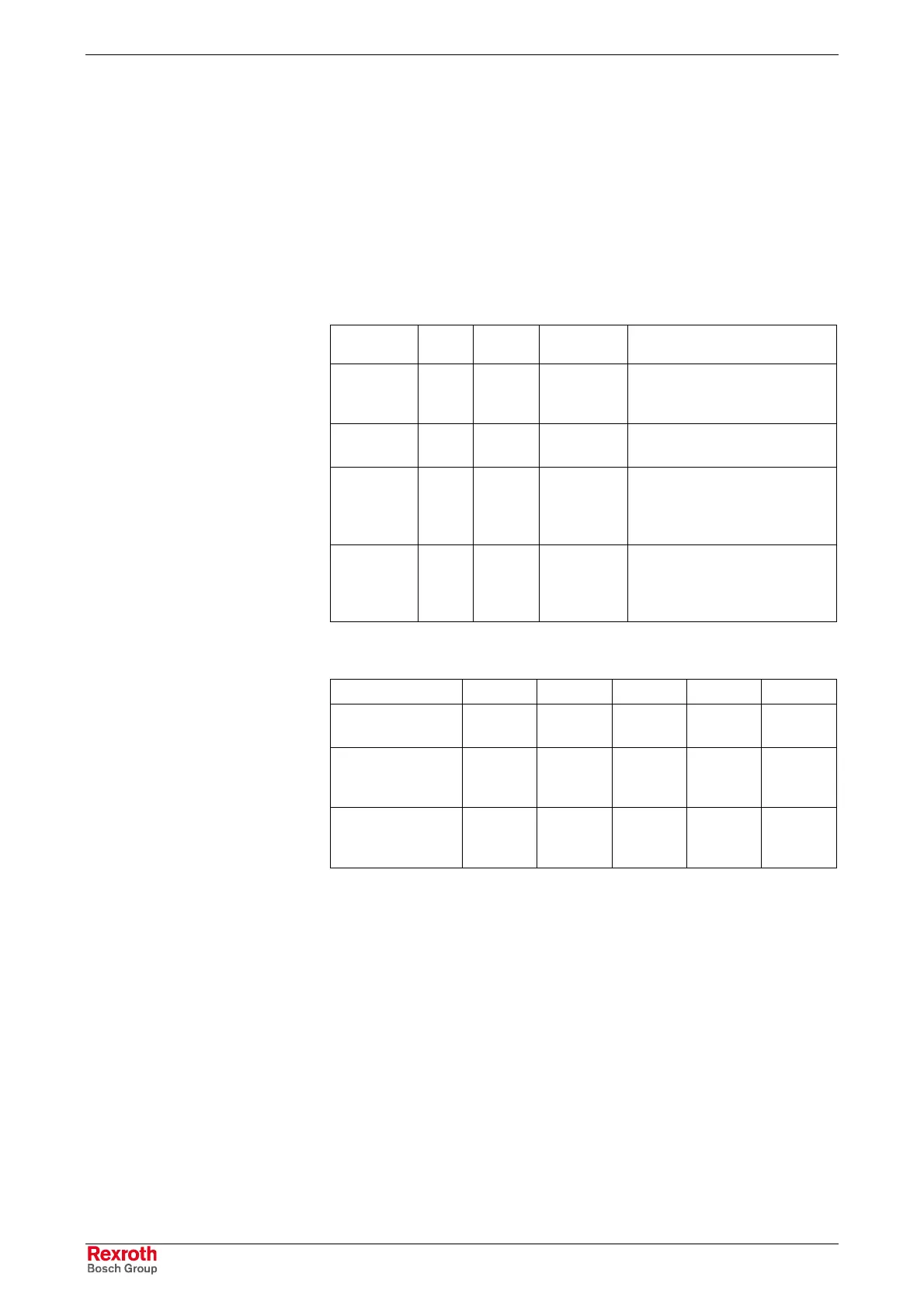

1. word 2. word 3. word 4. word

PCD section with

1x16 bit setpoint

CTW

STW

SP1

AV1

PPO type

1,3

PCD section with

up to 3

16 bit setpoints

CTW

STW

SP1

AV1

SP3

AV3

SP2

AV2

PPO type

2.4

PCD section with

1x32 bit setpoint

value and 1x16 bit

CTW

STW

SP1

AV1

SP2

AV2

PPO type

2.4

Fig. 15-11: Structure and sequence of the process data section

Loading...

Loading...