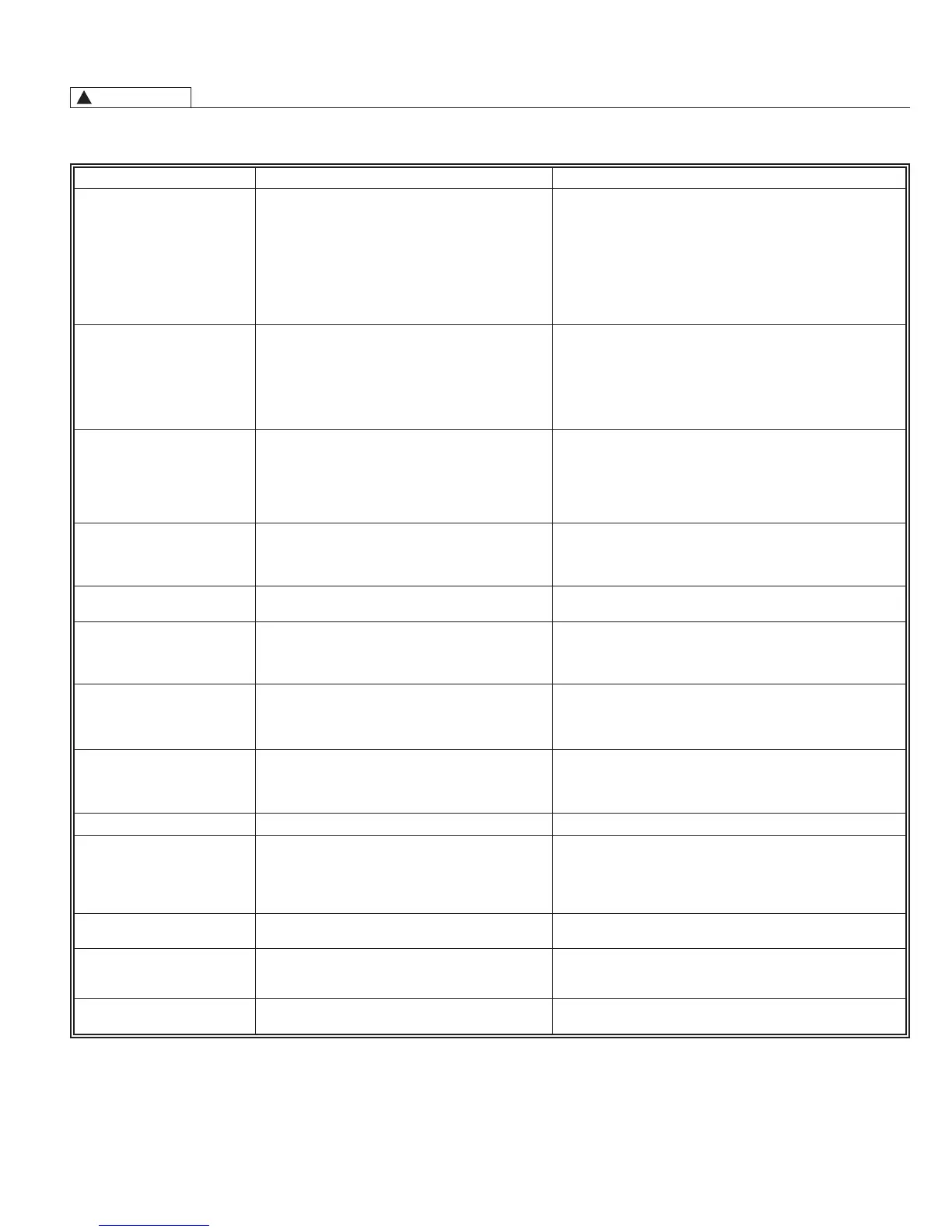

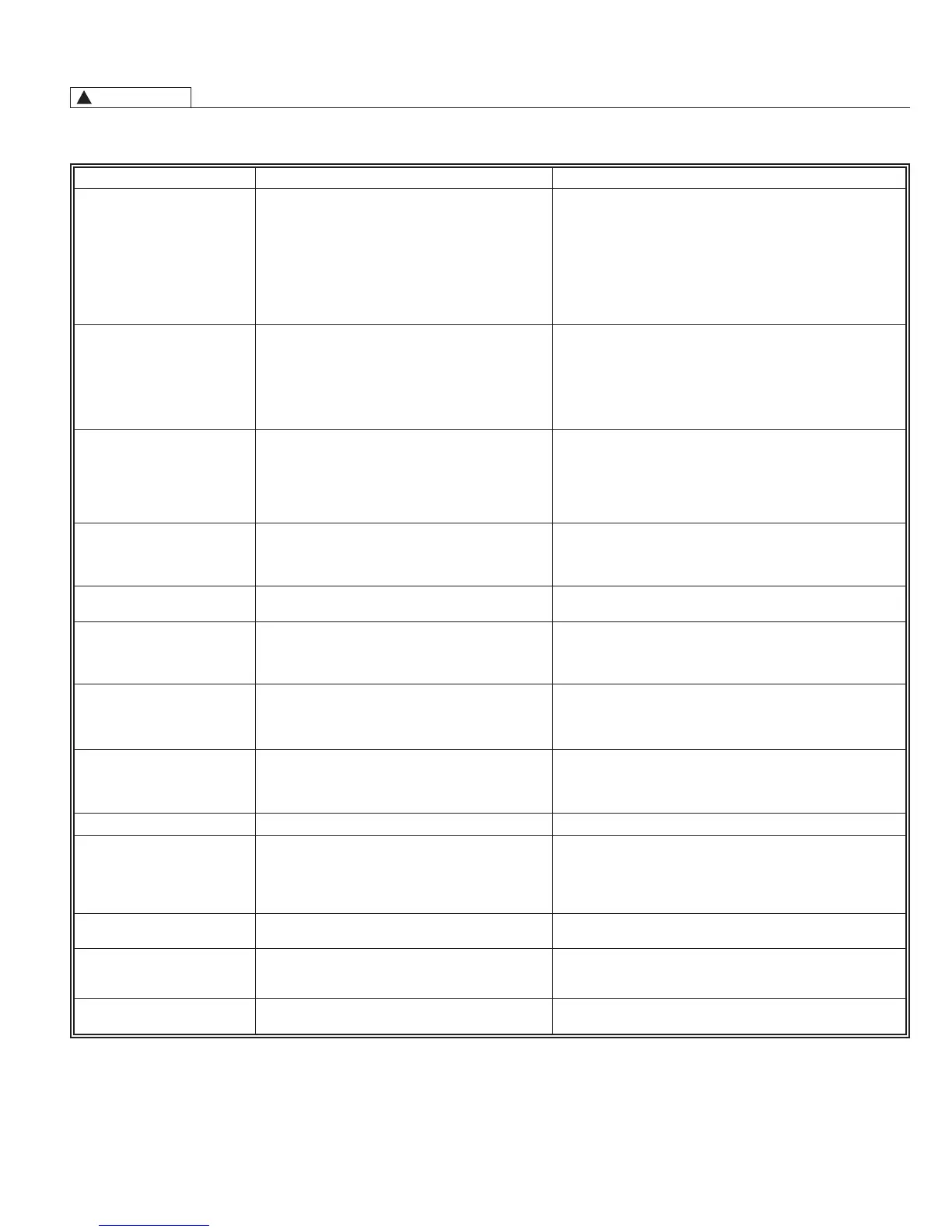

SYMPTOM POSSIBLE CAUSE REMEDY

U

nit will not run • Power off or loose electrical connection • Check for correct voltage at compressor contactor in control

box

• Thermostat out of calibration-set too high • Reset

• Defective contactor • Check for 24 volts at contactor coil - replace if contacts are

o

pen

•

Blown fuses • Replace fuses

•

Transformer defective • Check wiring-replace transformer

• High pressure control open (if provided) • Reset-also see high head pressure remedy-

• Interconnecting low voltage wiring damaged • Replace thermostat wiring

Condenser fan runs, compressor • Run capacitor defective (single phase only) • Replace

d

oesn’t • Loose connection • Check for correct voltage at compressor -

c

heck & tighten all connections

•

Compressor stuck, grounded or open motor winding, • Wait at least 2 hours for overload to reset.

open internal overload. If still open, replace the compressor.

• Low voltage condition At compressor terminals, voltage must be within 10% of rating

• Low voltage condition • Add start kit components

I

nsufficient cooling • Improperly sized unit • Recalculate load

•

Improper airflow • Check - should be approximately 400 CFM per ton.

• Incorrect refrigerant charge • Charge per procedure attached to unit service panel

• Air, non-condensibles or moisture in system • Recover refrigerant, evacuate & recharge, add filter drier

• Incorrect voltage • At compressor terminals, voltage must be within 10% of rating

plate volts when unit is operating.

Compressor short cycles • Incorrect voltage • At compressor terminals, voltage must be ±10% of

nameplate marking when unit is operating.

• Defective overload protector • Replace - check for correct voltage

• Refrigerant undercharge • Add refrigerant

Registers sweat • Low evaporator airflow • Increase speed of blower or reduce restriction - replace air

filter

High head-low vapor pressures • Restriction in liquid line, expansion device or filter drier • Remove or replace defective component

• Flow check piston size too small • Change to correct size piston

• Incorrect capillary tubes • Change coil assembly

• TXV does not open • Replace TXV

High head-high or normal vapor • Dirty condenser coil • Clean coil

pressure - Cooling mode • Refrigerant overcharge • Correct system charge

• Condenser fan not running • Repair or replace

• Air or non-condensibles in system • Recover refrigerant, evacuate & recharge

High head-high or normal vapor • Low air flow - condenser coil • Check filters - correct to speed

pressure - Heating mode • Refrigerant overcharge • Correct system charge

• Air or non-condensibles in system • Recover refrigerant, evacuate & recharge

• Dirty condenser coil • Check filter - clean coil

Low head-high vapor pressures • Defective Compressor valves • Replace compressor

Low vapor - cool compressor - • Low evaporator airflow • Increase speed of blower or reduce restriction - replace air

iced evaporator coil filter

• Operating below 65°F outdoors • Add Low Ambient Kit

• Moisture in system • Recover refrigerant - evacuate & recharge - add filter drier

• TXV limiting refrigerant flow • Replace TXV

High vapor pressure • Excessive load • Recheck load calculation

• Defective compressor • Replace

Fluctuating head & vapor • TXV hunting • Check TXV bulb clamp - check air distribution on coil - replace

pressures TXV

• Air or non-condensate in system • Recover refrigerant, evacuate & recharge

Gurgle or pulsing noise at • Air or non-condensibles in system • Recover refrigerant, evacuate & recharge

expansion device or liquid line

TROUBLE SHOOTING CHART

D

ISCONNECT ALL POWER TO UNIT BEFORE SERVICING. CONTACTOR MAY BREAK ONLY ONE SIDE. FAILURE

TO SHUT OFF POWER CAN CAUSE ELECTRICAL SHOCK RESULTING IN PERSONAL INJURY OR DEATH.

WARNING

!

SEE DEMAND DEFROST CONTROL SECTION FOR DEFROST BOARD FLASH CODES (6 TON UNIT ONLY).

83

Loading...

Loading...