Self-Opening Die Heads

The Model 815A Die Heads are self-opening die heads.

For

1

/

2

" through 2" pipe sizes, a trigger can be used to open

the die head when the thread is complete. For

1

/

8

" to

3

/

8

"

sizes, bolt and straight threads, and if desired for the

other sizes, the die head is manually opened when the

thread is complete.

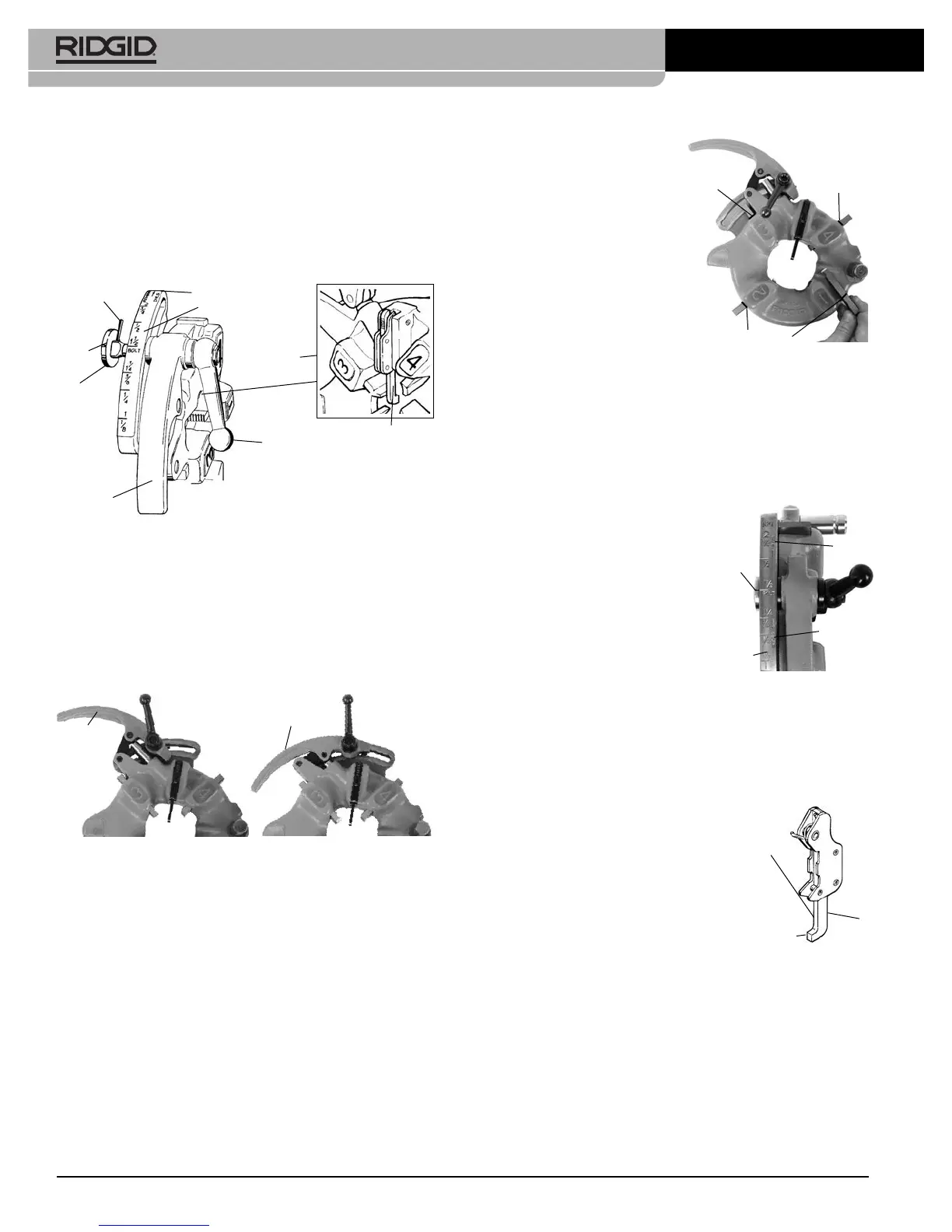

Figure 10 – Universal Self-Opening Die Head

Inserting/Changing the Dies

1. Place the die head with numbers facing up.

2. Make sure the trigger assembly is released and die

head OPEN by pulling the trigger slide away from the

die head. Stay clear of the spring loaded Throwout

Lever while releasing trigger assembly.

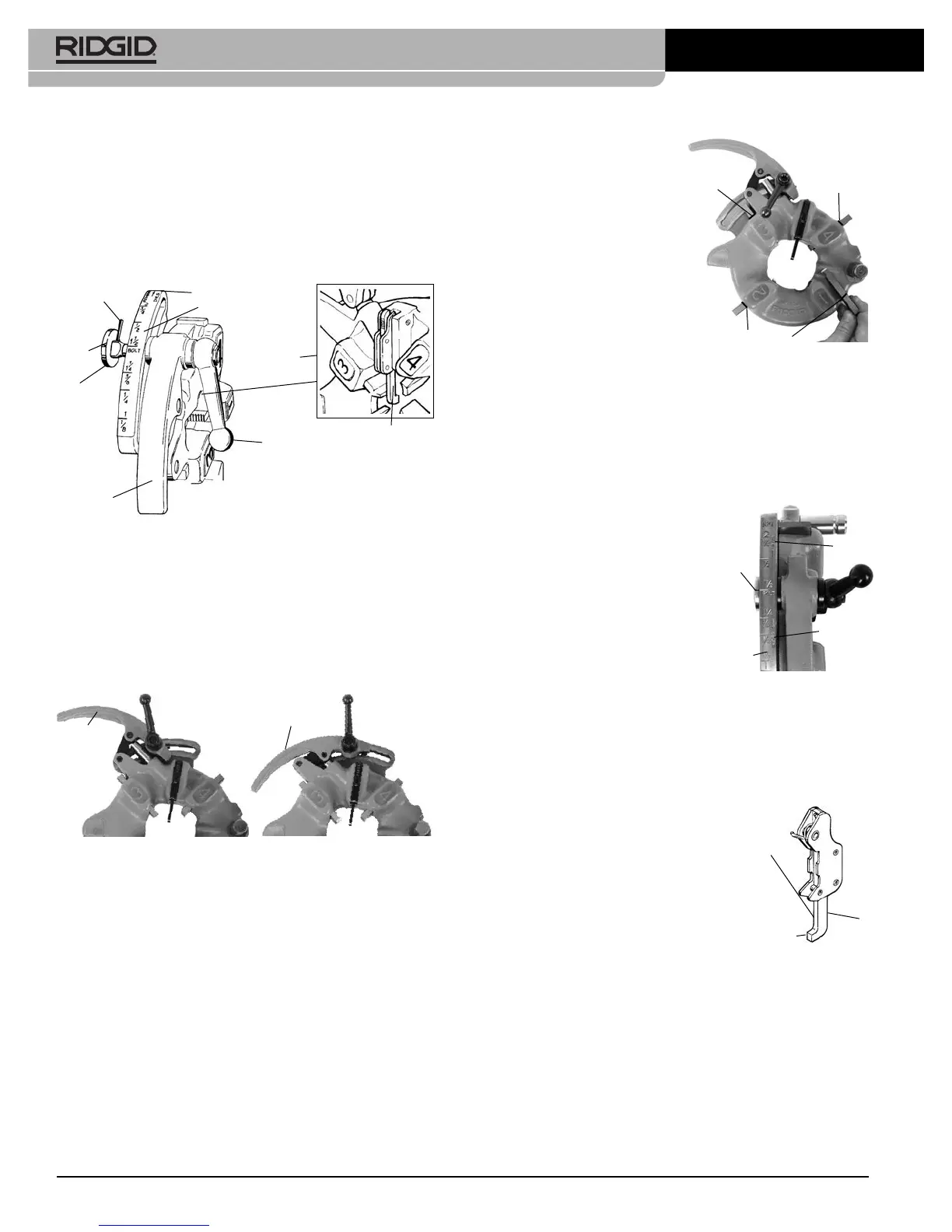

Figure 11 – Open/Closed Position

3. Loosen clamp lever ap proximately six full turns.

4. Pull lock screw out of size bar slot so roll pin will

bypass slot. Position size bar so that the index line on

lock screw is a ligned with the RE MOVE DIES mark.

5. Remove dies from the die head.

6. Insert appropriate dies into the die head, numbered

edge up until the indicator line is flush with the edge of

the die head (see Fi gure 12). Num bers on the dies

must cor res pond with those on the die head slots.

Always change dies as sets – do not mix dies from dif-

ferent sets.

7. Move size bar so in dex

line on lock screw is a -

ligned with desired size

mark. Adjust die insertion

as needed to allow move-

ment.

8. Make sure roll pin points

to ward REMOVE DIES

mark.

9. Tighten the clamp lever.

Adjusting Thread Size

1 Install the die head per the Thread ing Machine Instruc -

tions and move the die head into threading position.

2. Loosen clamp lever.

3. Position size bar so index line on lock screw is aligned

with desired size mark on size bar.

4. If thread size needs to be ad -

justed, set the lock screw index

line slightly off the mark on size

bar in the direction of OVER

(larger dia meter thread, less

turns of fitting engagement) or

UNDER (smaller thread dia -

meter, more turns of fitting en -

gagement) markings.

5. Tighten clamp lever.

Trigger Slide Adjustment

Position the Trigger Slide for the size of pipe being thread-

ed (see Figure 14).

•

1

/

2

" and

3

/

4

" – End of pipe should hit foot of Trigger

Slide.

• 1" to 2" – End of pipe should hit

the shank of the Trigger Slide.

For

•

1

/

8

", ¼" and

3

/

8

" pipe

• Longer or shorter threads

• Bolt threading

Push trigger slide up and out of the

way. Die head must be opened man-

ually.

Opening the Die Head at the End of the Thread

When using trigger it will contact the end of pipe, causing

the die head to automatically open. Stay clear of the

spring loaded Throwout Lever when it releases.

10

300 Compact/1233 Threading Machines

Throwout

Lever

Open

Closed

Throwout

Lever

Figure 12 – Inserting Dies

Indicator Line

Indicator

Line

Indicator

Line

Figure 13 – Adjusting

Thread Size

Lock

Screw

Index

Line

Size

Bar

“Over”

“Under”

Throwout

Lever

Trigger

Assembly

Clamp Lever

Size Bar

Roll Pin

Index

Line

Lock

Screw

“Remove Dies” Mark

Trigger

Slide

1" thru 2"

pipe hit

this

surface

Trigger

Slide

1

/

2

" and

3

/

4

"

pipe hit this

surface

Figure 14 – Setting

the

Trigger

Loading...

Loading...