What to do if there is no cutting oil flow in my RIDGID Industrial Equipment?

- HHeather GrayAug 9, 2025

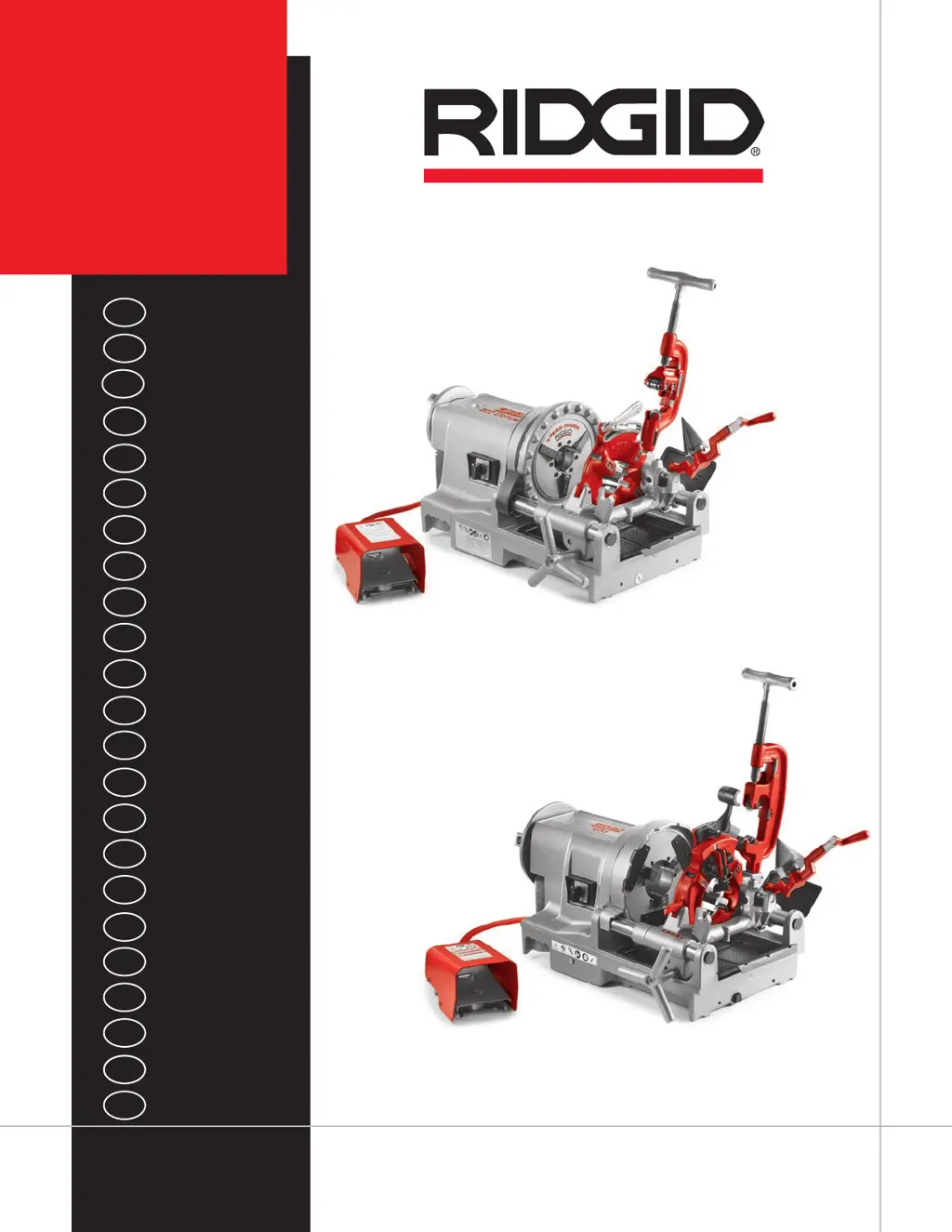

To address the issue of no cutting oil flow in your RIDGID Industrial Equipment, start by filling the oil reservoir. If the problem persists, the oil may be dirty or contaminated; in this case, replace it with RIDGID® Thread Cutting Oil. Also, the Oil Screen may be plugged, so you should clean the screen. Finally, ensure that the oil flow rate is properly set and that the die head is in the threading position.