5

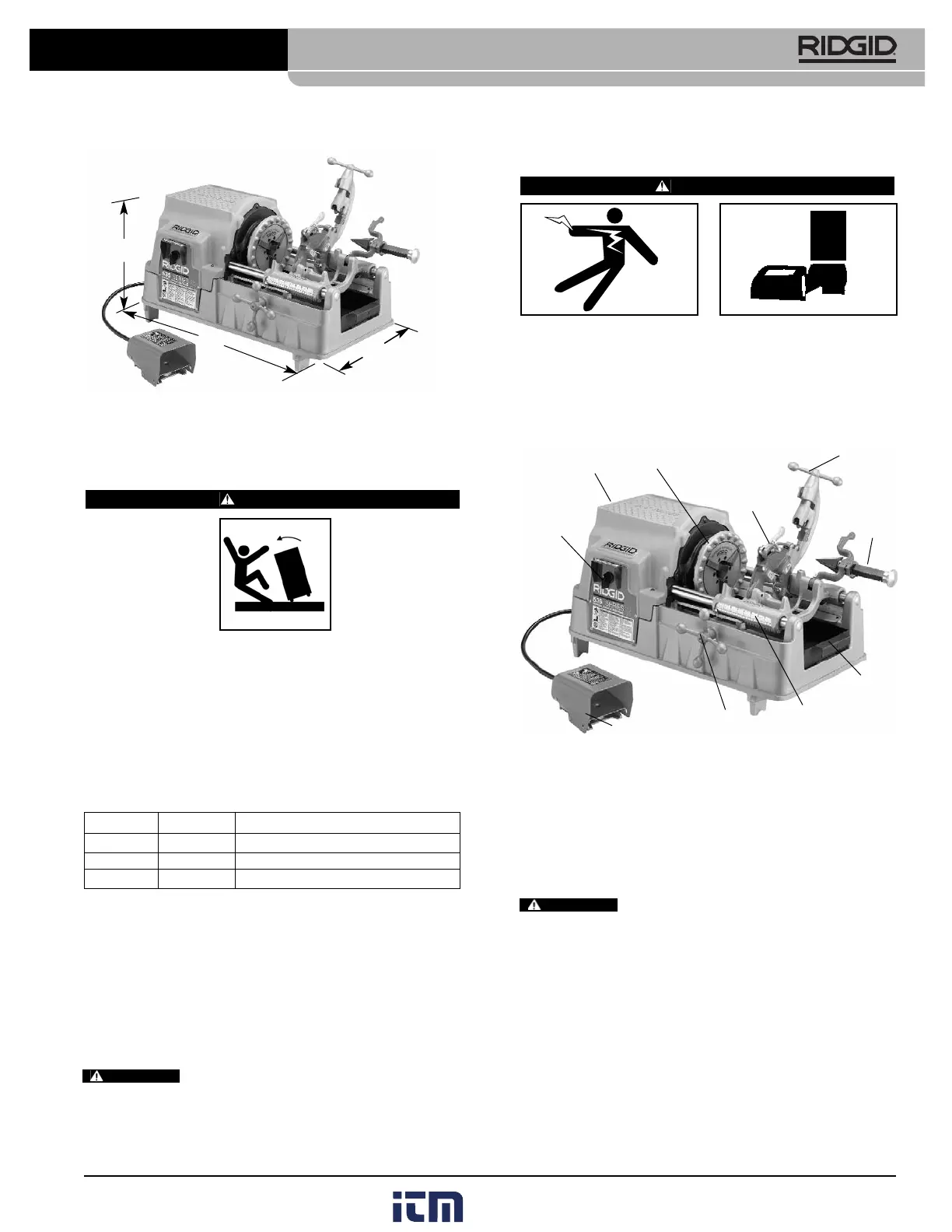

Figure 2 – No. 535 Machine Dimensions

Machine Assembly

WARNING

To prevent serious injury, proper assembly of the

Threading Machine is required. The following pro-

cedures should be followed:

Mounting Machine To Stand

1. The machine is designed to mount on the three uni-

versal stands listed below.

Figure 3

Mounting Machine To Bench

1. If a stand is not used, the machine should be mount-

ed to a stable bench. To mount the unit on a bench,

use four (4)

5

/

16

″ bolts in holes provided at each corner

of machine base. Base dimensions are shown in

Figure 2

.

Failure to mount the threading machine to

a stable stand or bench may result in tipping and serious

injury.

Machine Inspection

WARNING

To prevent serious injury, inspect your Threading

Machine. The following inspection procedures

should be performed on a daily basis:

1. Make sure Threading Machine is unplugged and the

directional switch is set to the OFF position

(Figure 4)

.

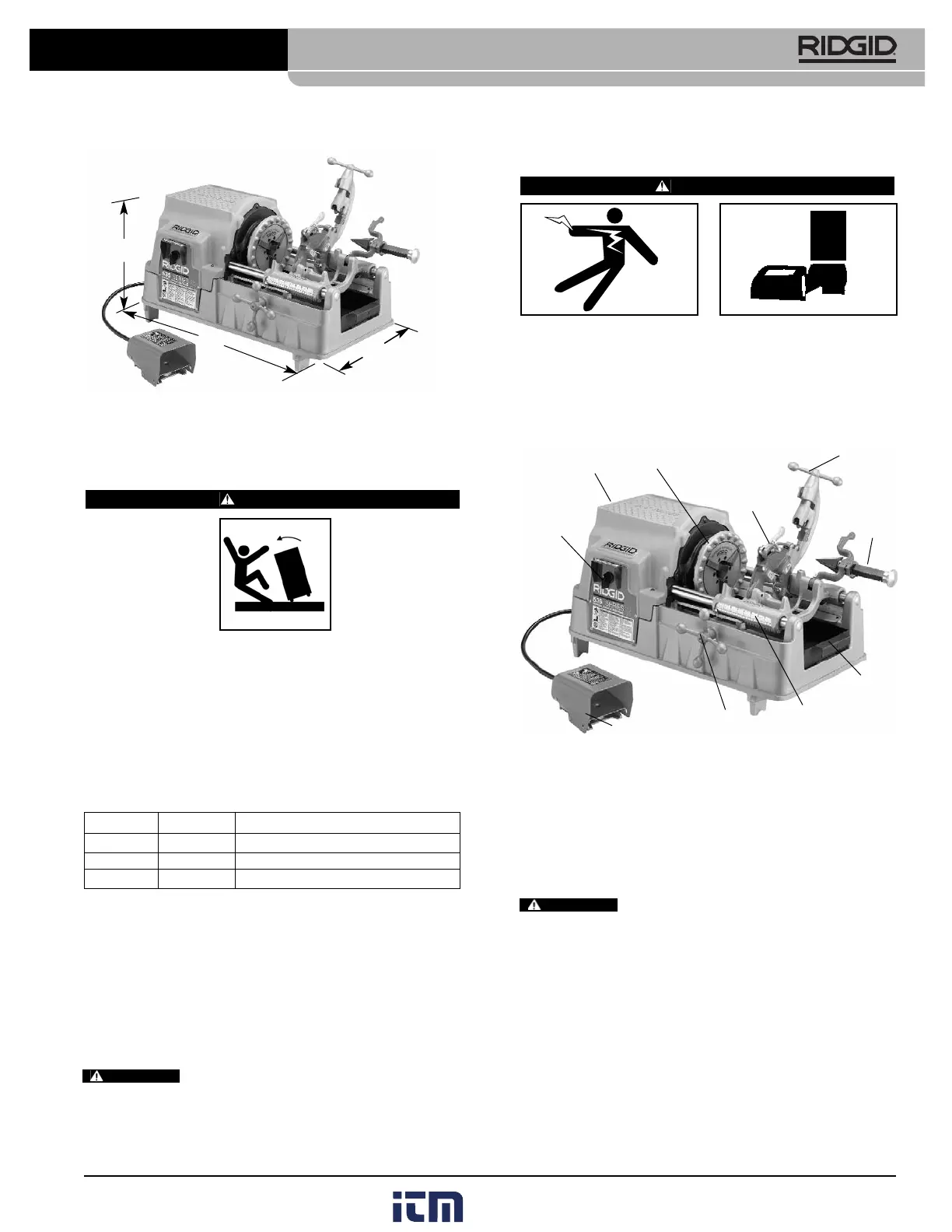

Figure 4 – No. 535 Pipe and Bolt Threading Machine

2. Clean the speed chuck jaws with a wire brush.

3. Inspect the jaw inserts for excessive wear. Refer to the

Maintenance Instructions if they need to be replaced.

4. Make sure the foot switch is present and attached to

the Threading Machine

(Figure 4)

.

Do not operate the Threading Machine

without a foot switch.

5. Inspect the power cord and plug for damage. If the

plug has been modified, is missing the grounding

pin or if the cord is damaged, do not use the

Threading Machine until the cord has been replaced.

6. Inspect the Threading Machine for any broken, miss-

ing, misaligned or binding parts as well as any other

conditions which may affect the safe and normal

operation of the machine. If any of these conditions

are present, do not use the Threading Machine until

any problem has been repaired.

535 Manual Pipe and Bolt Threading Machine

WARNING

Machine Stands

Model No. Cat. No. Description

100A 92457 Universal Leg & Tray Stand

150A 92467 Universal Wheel & Tray Stand

200A 92462 Universal Wheel & Cabinet Stand

20.8″

38.1″

20.5″

Centering

Device

(Not Shown)

Chuck Handwheel

Quick or

Self-Opening

Die Head

No. 820

Cutter

(Standard)

No. 341

Reamer

Chip

Pan

REV/OFF/FOR

Switch

Foot Switch

Carriage Handwheel

Length Gauge

WARNING

Loading...

Loading...