13

R

E

M

O

V

E

ASSEMBLY

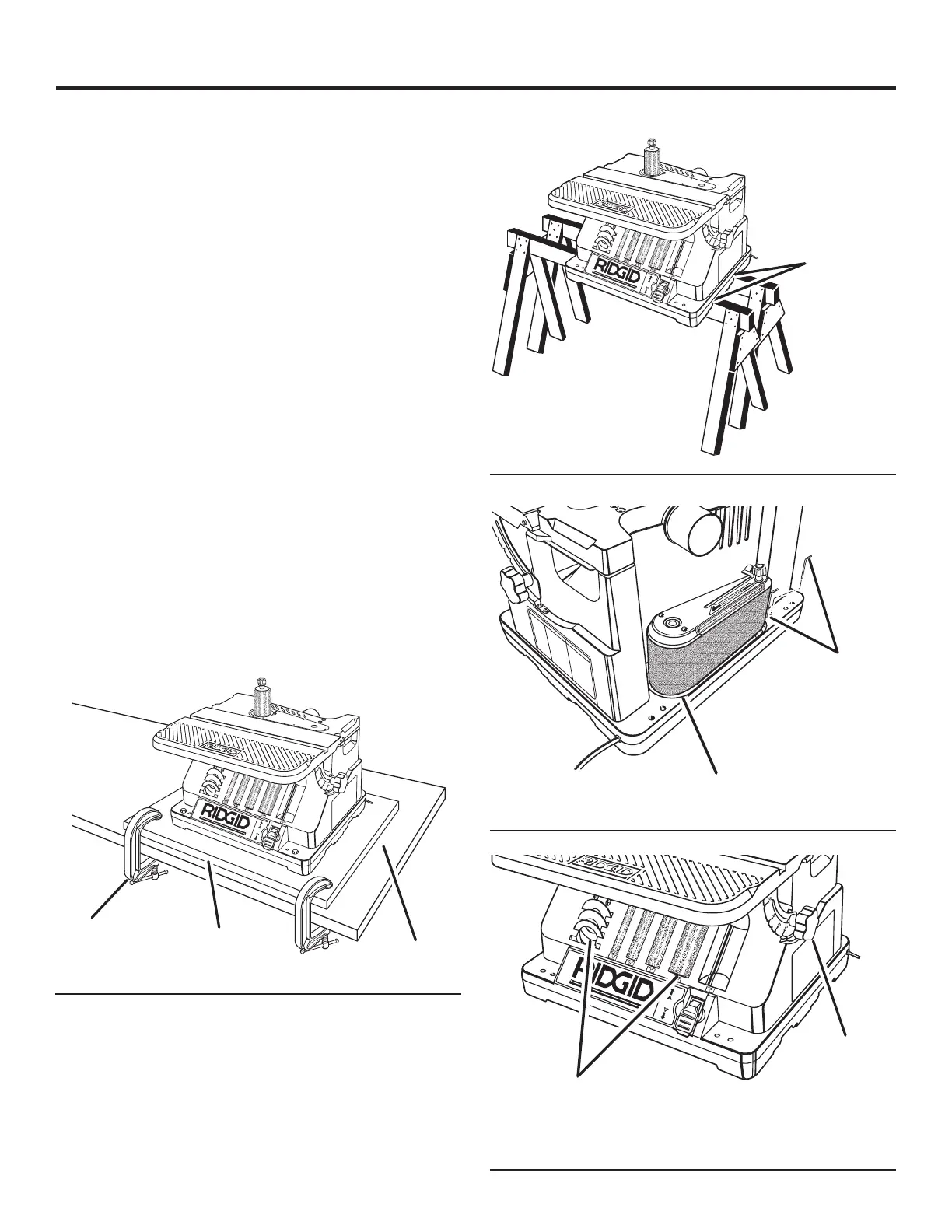

CLAMPING SANDER TO WORKBENCH

See Figure 7.

An alternative method of mounting is to fasten the sander

to a mounting board. The board should be sufficient size to

avoid tipping while in use. Any good grade of plywood or

chipboard with a 3/4 in. thickness is recommended. (Thinner

chipboard can break.)

Once sander is mounted to board, clamp to workbench.

NOTE: For proper stability, holes must be countersunk so

screw heads are flush with the surface of supporting board.

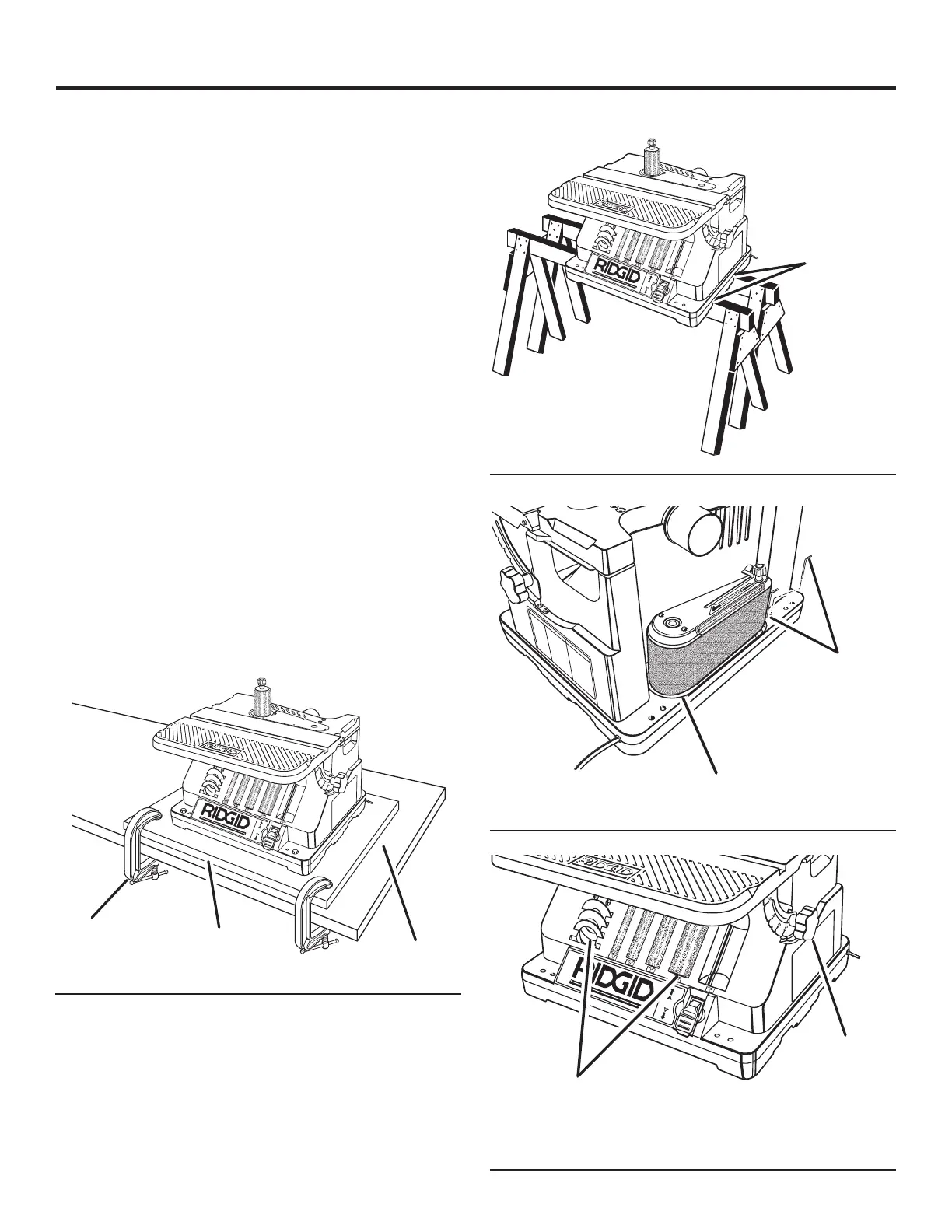

SUPPORTING OSCILLATING EDGE BELT/

SPINDLE SANDER TO SAWHORSES

See Figure 8.

The sander has provisions for being supported by saw-

horses. The sawhorse can be built with the crosspiece either

vertical or horizontal. Make sure the sawhorses are secure.

PARTS STORAGE

See Figures 9 - 10.

On board storage has been provided for all washers, spac-

ers, drums, sleeves and hex keys. All front loaded parts

can be protected from incidental dislodging by lowering

the table all the way down until it rests against the base and

tightening the knob.

Storage for the sanding belt assembly is provided in the

pocket on the rear of the base.

R

E

M

O

V

E

HEX KEY

STORAGE

AREA

SANDING SLEEVES /

THROAT PLATES / WASH-

ERS STORAGE AREA

aaaa

TABLE INSERT / SANDING

BELT STORAGE

TABLE LOCK

KNOB

SLOTS FOR

SAW HORSE

MOUNTING

Fig. 7

Fig. 9

Fig. 10

MOUNTING

BOARD

C-CLAMP

WORKBENCH

Fig. 8

Loading...

Loading...