8

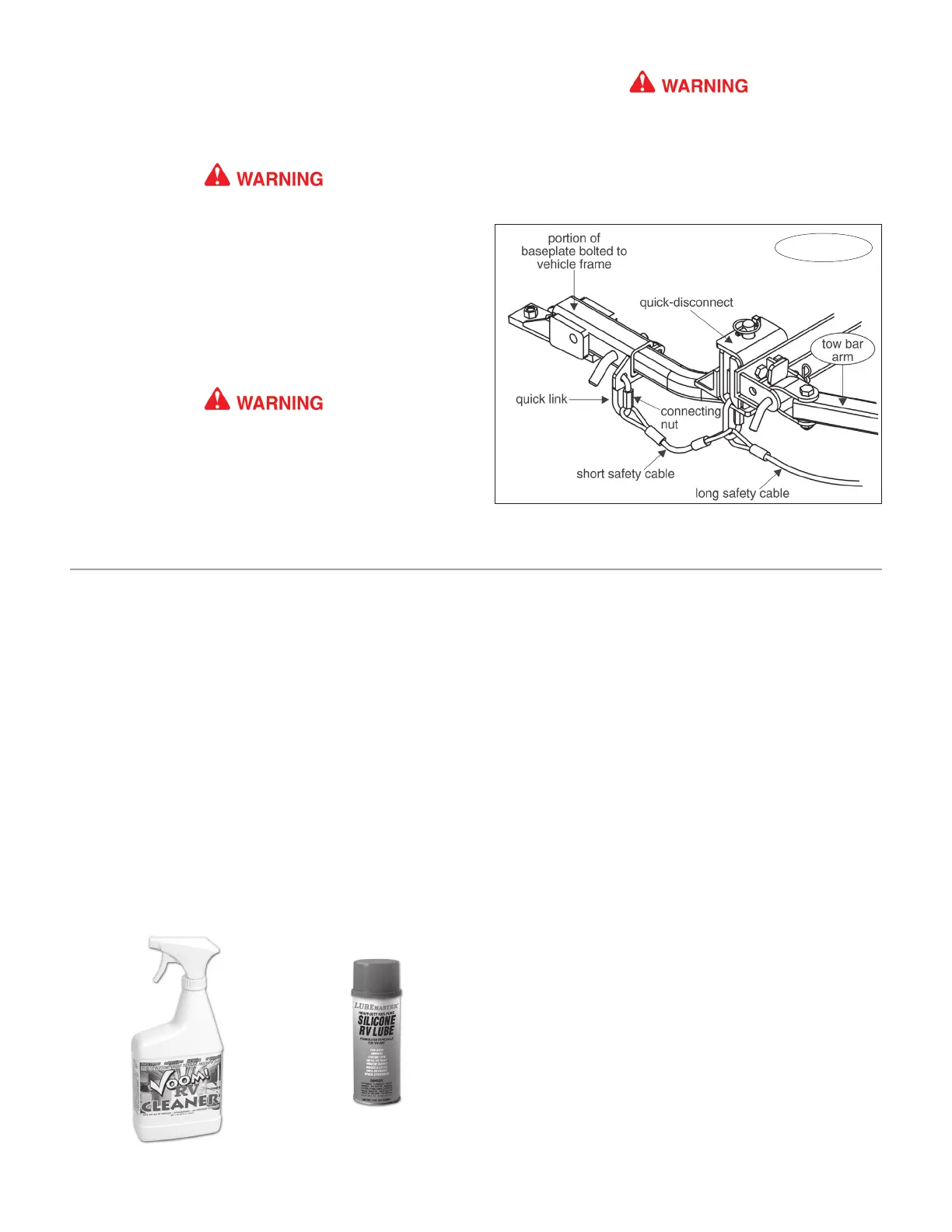

Proper installation of safety cables

continued from preceding page

If your ROADMASTER baseplate kit contains short safe-

ty cables, refer to the installation instructions for complete

information.

The safety cables must be carefully routed so that

they cannot become pinched, frayed, scraped or oth-

erwise damaged, and so they will not drag when going

over dips or low spots.

Do not use the cables if they show any signs of

wear or damage — immediately discontinue towing and

replace the cables.

Failure to follow these instructions will result in

cable failure, which may cause property damage, per-

sonal injury or even death.

If the quick links are not completely tightened, with

the loop closed, the safety cables may detach. In the

event of a towing system failure, the towed vehicle will

detach, which may cause property damage, personal

injury or even death.

If your towing system requires two sets of safety

cables, always use both the long and the short safety

cables. Connect them as shown in Figure 12. Other-

wise, in the event of a towing system failure, the towed

vehicle will detach, which may cause property damage,

personal injury or even death.

Figure 12

CARE AND CLEANING

As is the case with most precision equipment, frequent

cleaning and care results in better performance and lon-

gevity. Use the following guidelines to keep your tow bar

clean and well-lubricated.

Always clean the tow bar before lubricating. Use a wa-

ter-soluble cleaner such as Voom RV (part number 9911,

shown below) — it does an exceptional job of breaking

down road film, dirt and grease.

CAUTION

Do not use petroleum-based products to clean or lu-

bricate the tow bar. Petroleum will attract dirt and dust,

which will impede the operation of the collars and pins,

and/or other components. Certain petroleum products

may also corrode non-metallic components.

Damage caused by using a petroleum-based prod-

uct to clean or lubricate the tow bar is not covered

Voom RV cleaner and degreaser

(part number 9911)

LubeMaster silicone spray

(part number 747) —

meets Volatile Organic Compound

(VOC) standards

under warranty.

Spray a liberal amount of cleaner on the tow bar and

into both collars and pins (Figure 4). Move the coupler

(Figure 4) to the left and the right, to work the cleaner

into the collars and pins.

Clean the interior of the coupler, and wipe away the old

grease, dirt and debris.

After cleaning the tow bar, wipe any remaining cleaner

away.

Now that you have a clean, dry tow bar, use a dry

silicone aerosol, such as LubeMaster (part number 747,

shown below), to lubricate the tow bar — spray a liberal

amount of silicone into the collars and the pins.

Lubricate the coupler ball socket and ball clamp (Figure

1) with wheel bearing grease; lubricate all other moving

components of the coupler with SAE 30 weight oil. (See

“Atwood coupler information.”)

Extended storage — before storing your tow bar for an

extended period of time, clean and lubricate it as above.

Store the tow bar in a dry, enclosed area, to protect it from

the elements.

Loading...

Loading...