(2)

Install needle bearing to small end of

connecting rod.

(3)

Assemble piston and connecting

rod

with

piston pin and clips. (See page

14,

Fig.

15.)

Set the

"M"

mark stamped on piston top to

flywheel

side

of

piston.

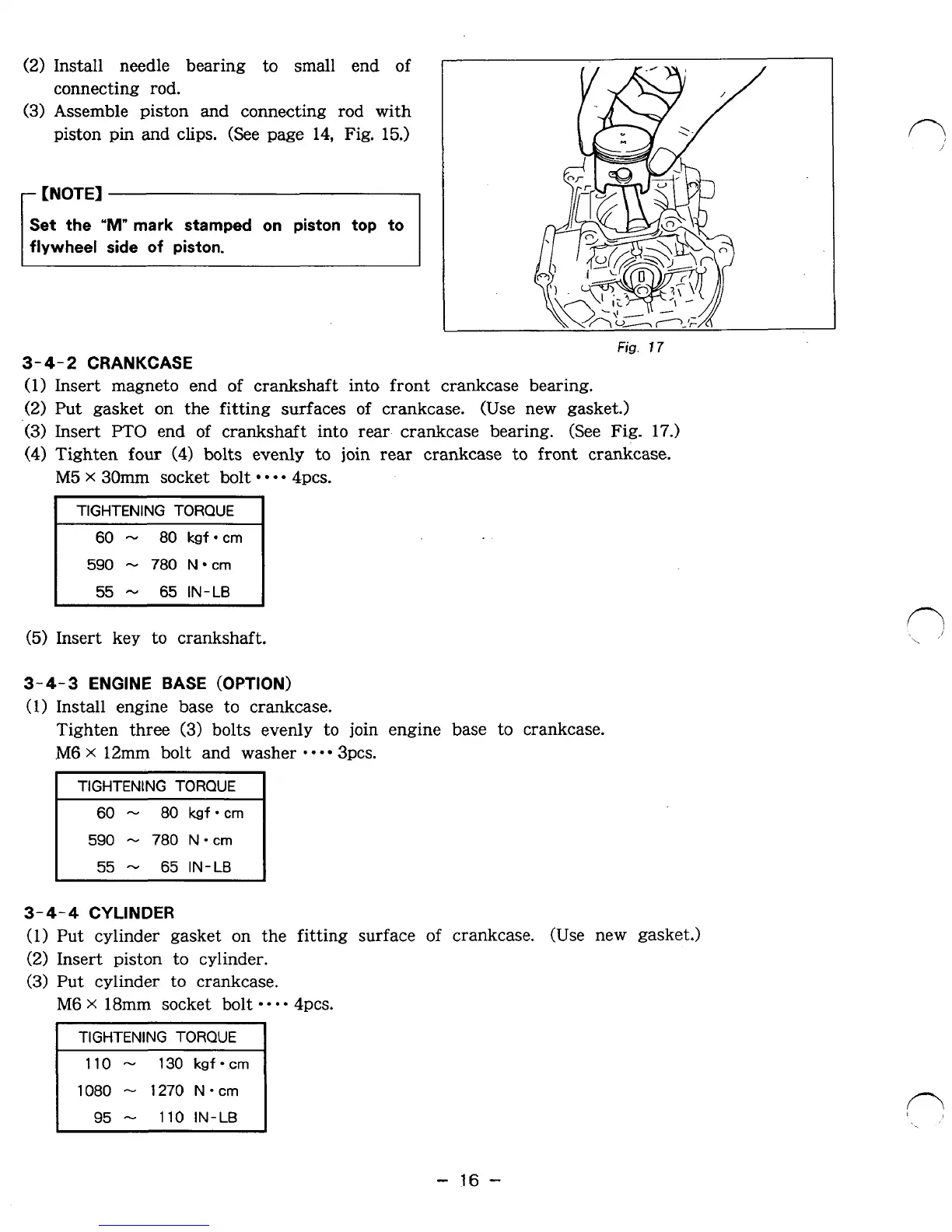

Fig.

17

3-4-2

CRANKCASE

(1)

Insert magneto end of crankshaft into front crankcase bearing.

(2)

Put gasket on the fitting surfaces

of

crankcase. (Use new gasket.)

(3)

Insert

FTO

end of crankshaft into rear crankcase bearing. (See Fig.

17.)

(4)

Tighten

four

(4)

bolts evenly to join rear crankcase to front crankcase.

M5

X

30mm socket bolt

0.

4pcs.

TIGHTENING TORQUE

60

-

80

kgf

*cm

590

-

780

N

crn

55

-

65

IN-LB

(5)

Insert key to crankshaft.

3-4-3

ENGINE

BASE

(OPTION)

(1)

Install engine base to crankcase.

I

Tighten three

(3)

bolts evenly

to

join engine base to crankcase.

M6

x

12mm bolt and washer

*e*

3pcs.

TIGHTENING TORQUE

80

kgf

*cm

590

-

780

N

-

cm

55

-

65

IN-LB

3-4-4

CYLINDER

(1) Put cylinder gasket on the fitting surface of crankcase. (Use new gasket.)

(2) Insert piston to cylinder.

(3)

Put cylinder

to

crankcase.

M6

X

18mm socket bolt

-0

-0

4pcs.

1080

-

1270

N*cm

n

i

,

-

16

-

Loading...

Loading...