-

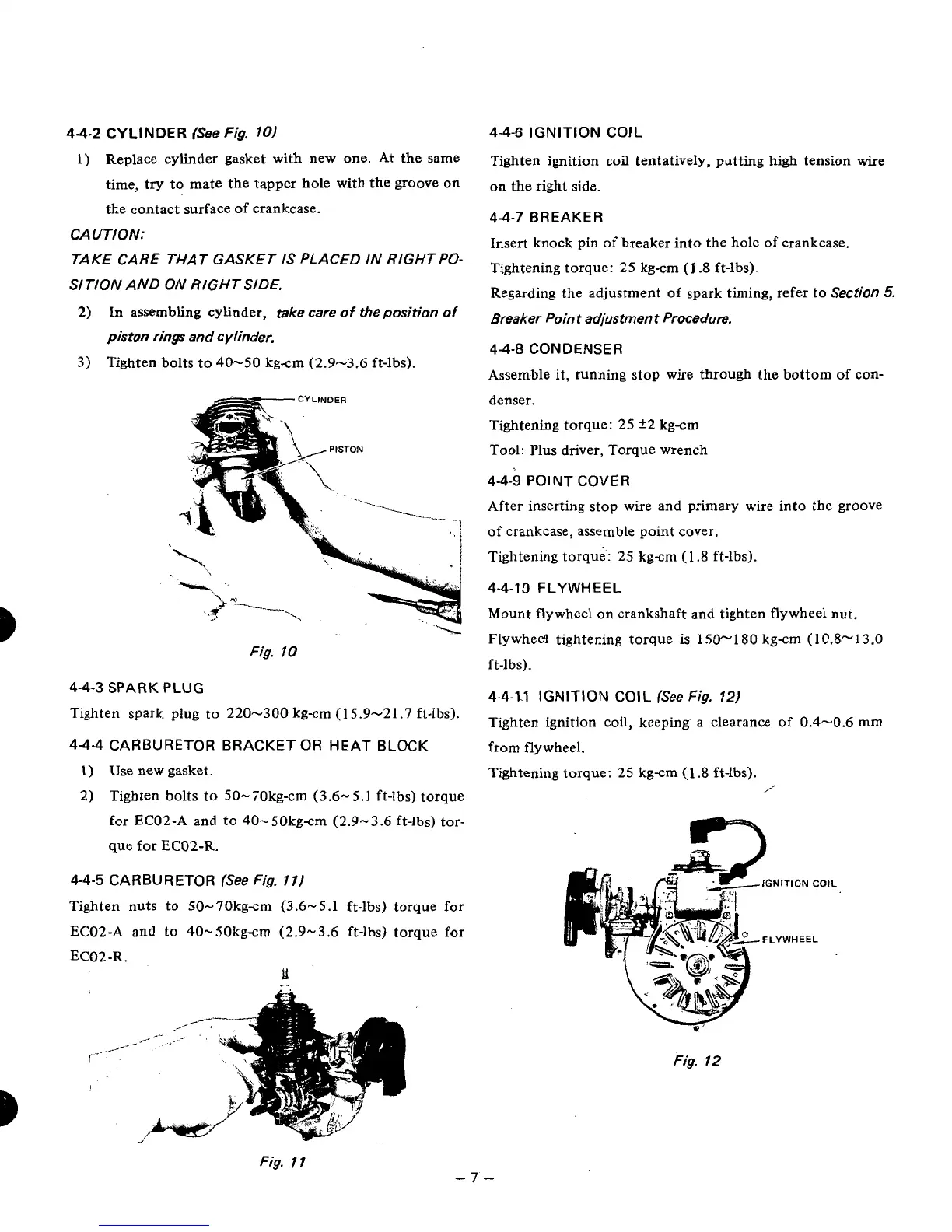

4-4-2

CYLINDER

(See

Fig.

10)

-

1) Replace cylinder gasket with new one. At the same

time,

try

to mate the tapper hole with the groove

on

the contact surface

of

crankcase.

CAUTION:

TAKE CARE THAT GASKET

IS

PLACED

IN

RIGHTPO-

SITION

AND

ON

RIGHTSIDE.

2)

In assembling cylinder,

take care

of

the position

of

piston rings and cylinder.

3)

Tighten bolts to 40-50 kg-cm (2.9-3.6 ft-lbs).

"A

Fig.

10

4-4-3 SPARK

PLUG

Tighten spark plug to 220-300 kgcm (1 5.9-21.7 ft-lbs).

4-4-4 CARBURETOR BRACKET

OR

HEAT BLOCK

1)

Use

new

gasket.

2) Tighten bolts to 50-70kg-cm (3.6- 5.1 ft-lbs) torque

for EC02-A and to 40-5Okgcm (2.9-3.6 ft-lbs) tor-

que

for

ECO2-R.

4-4-5 CARBURETOR

(See

Fig.

11)

Tighten nuts to 50-7Okgcm (3.6-5.1 ft-lbs) torque for

ECO2-A and to 40-50kgcm (2.9-3.6 ft-lbs) torque for

EC02

-R

.

II

4-4-6

IGNITION COIL

Tighten ignition

coil

tentatively, putting high tension

on

the right side.

4-4-7 BREAKER

Insert knock pin

of

breaker into the hole of crankcase.

Tightening torque: 25 kg-cm

(1.8

ft-lbs).

wire

Regarding the adjustment of spark timing, refer to

Section

5.

Breaker Point adjustment Procedure.

4-4-8 CONDENSER

Assemble it, running stop wire through the bottom of con-

denser.

Tightening torque: 25

k2

kgcm

Tool: Plus driver, Torque wrench

4-4-9 POINT

COVER

After inserting stop

wire

and primary wire into the groove

of crankcase, assemble point cover,

Tightening torque: 25 kgcm (1.8 ft-lbs).

4-4-10 FLYWHEEL

Mount flywheel on crankshaft and tighten flywheel nut.

Flywheel tightening torque

is

150-180 kgcm (10.8-13.0

ft-lbs).

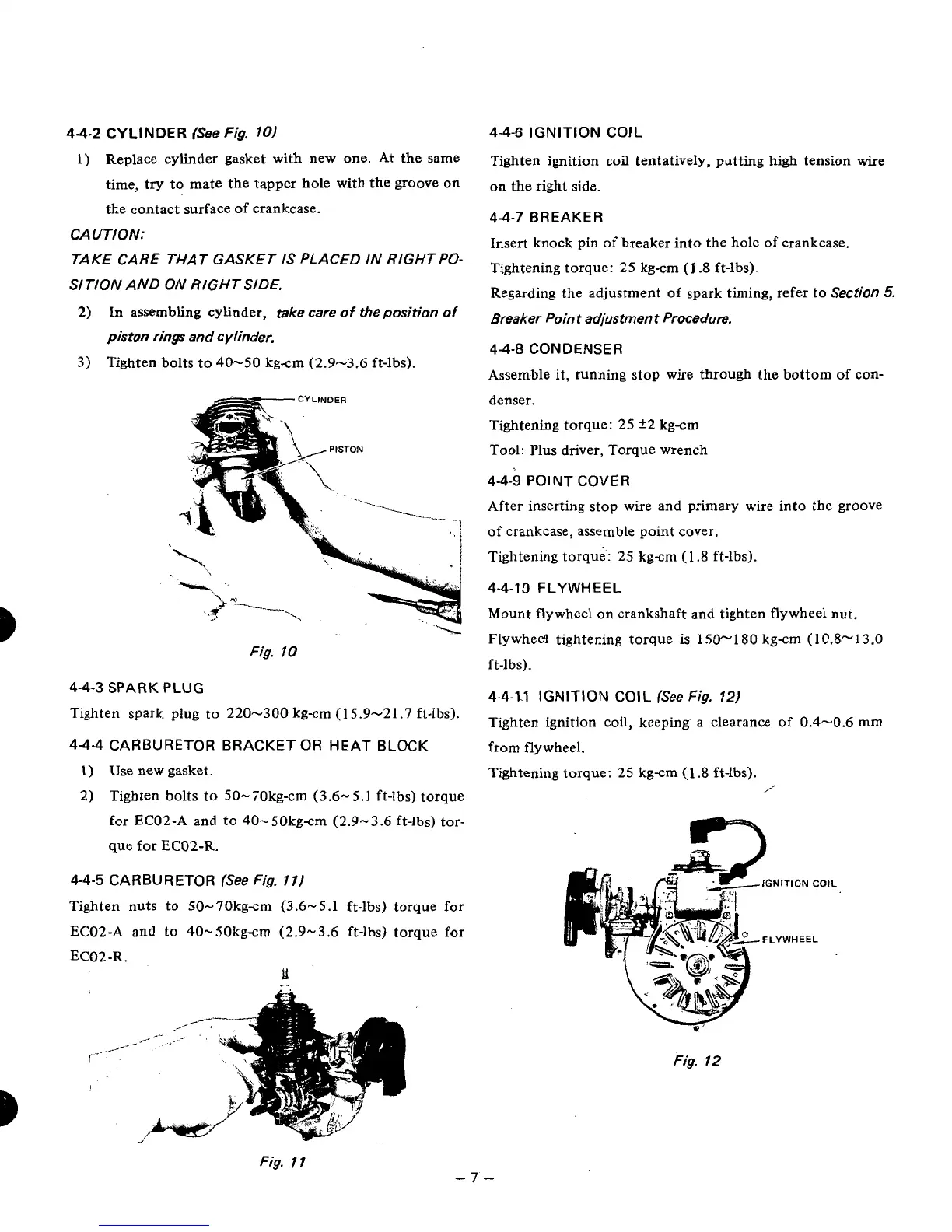

4-4-1.1 IGNITION

COIL

(See

Fig.

12)

Tighten ignition coil, keeping' a clearance of 0.4-0.6 mm

from

flywheel.

Tightening torque: 25 kg-cm

(1.8

ft-Lbs).

/

,NIT1

-YWI

ON

COIL

HEEL

Fig,

12

Fig,

1

1

-7-

Loading...

Loading...