12 Rockwell Automation Publication 440R-RM003A-EN-P - July 2021

Chapter 2 CU3 Control Unit

Threshold and Delay

Settings

Both the CU3 control unit and the MSR55P safety relay have a potentiometer

for adjusting the back EMF threshold setting. To access the threshold setting

adjustment in the CU3 control unit, you must open the front cover. The

MSR55P safety relay has the threshold setting adjustment on the front face.

In addition, the MSR55P safety relay has a second potentiometer on the front

face. This potentiometer is for adjusting a delay time from when standstill is

detected to when the outputs are energized. This feature provides additional

assurance that the motor has achieved a steady state speed that is considered

safe.

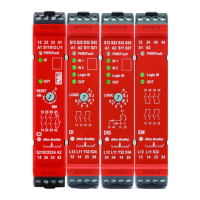

Terminal Locations and

Panel Space

Figure 2 on page 13 shows the relay sizes and terminal locations. The CU3

control unit has one row of terminals at the top and bottom. The MSR55P

safety relay has two rows of terminals at the top and bottom to accommodate

the features that the CU3 control unit does not have.

Both control units are 45 mm (1.77 in.) wide. The MSR55P safety relay is taller.

To achieve optimal heat dissipation, 50 mm (2 in.) of spacing is recommended

above and below each control unit.

Table 2 - CU3 Catalog Options

Cat. No. Supply Voltage

Standstill Monitoring

Voltage Threshold

Typical Applications

440R-S35001 24V AC/DC

Up to 2.5V Induction motors

440R-S35002 110V AC

440R-S35002 230V AC

Table 3 - MSR55P Catalog Options

Cat. No. Supply Voltage

Standstill Monitoring

Voltage Threshold

Typical Applications

440R-S35011 24V DC

20...400 mV Induction motors

440R-S35012 115V AC

440R-S35013 230V AC

440R-S35014 24V DC

200 mV…4V

Servo (permanent magnet)

motors

440R-S35015 115V AC

440R-S35016 230V AC

Loading...

Loading...