Maintenance

Repair

96 MagneMotion

Rockwell Automation Publication MMI-UM037A-EN-P - April 2020

7. Store the removed puck in its original shipping container, or wrap it in bubble-wrap,

for protection. Do not move one puck over, or near, the other puck.

8. Remove the remaining puck from the fixture and store it in its original shipping con-

tainer, or wrap it in bubble-wrap, for protection. Do not move one puck over, or near,

the other puck.

9. Service the pucks as required.

Replace Individual Wheeled Puck Wear Surfaces

This procedure provides instructions to replace worn wear surfaces on the following wheeled

pucks, which are used in tandem wheeled pucks:

• PN-543023, Wheeled Puck, Tandem, HP, Single

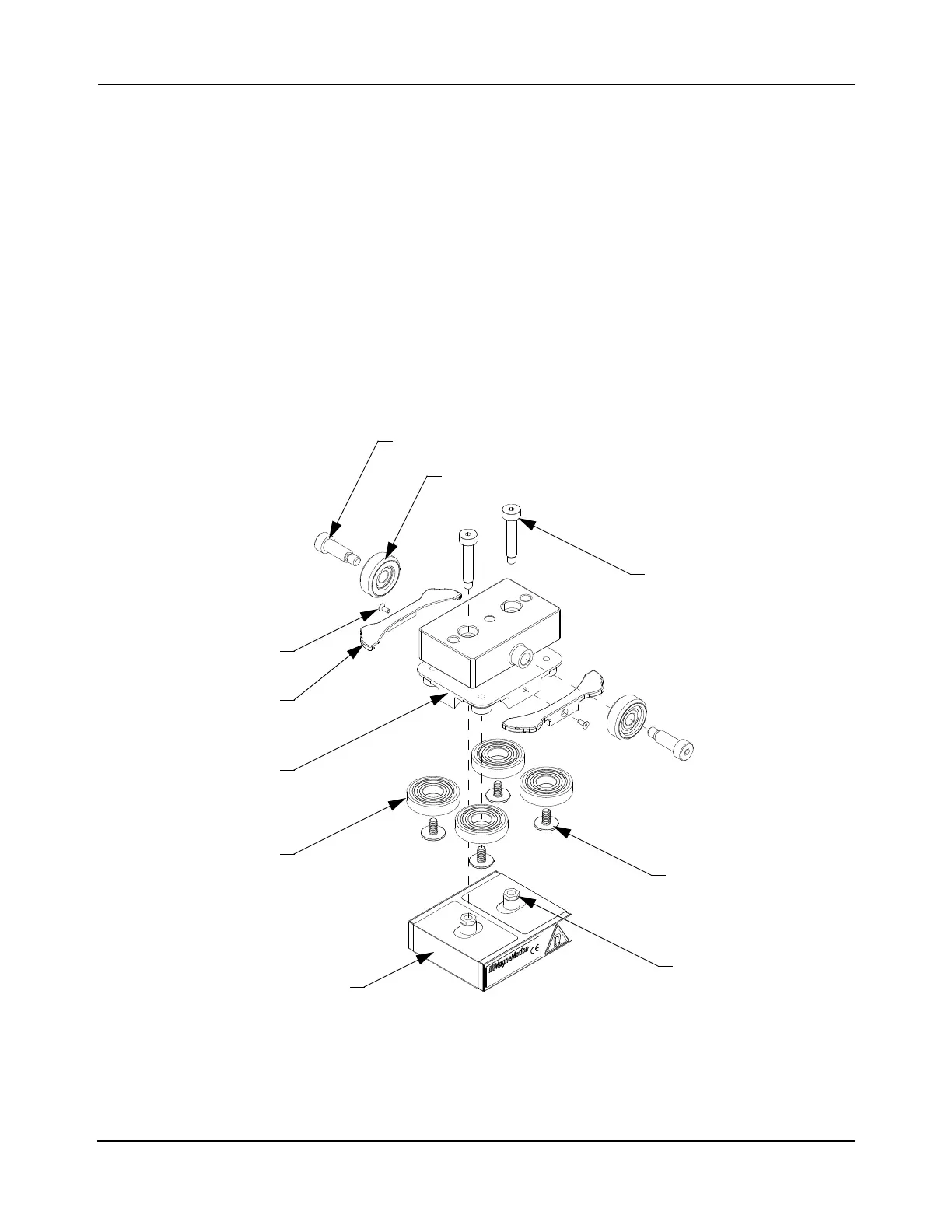

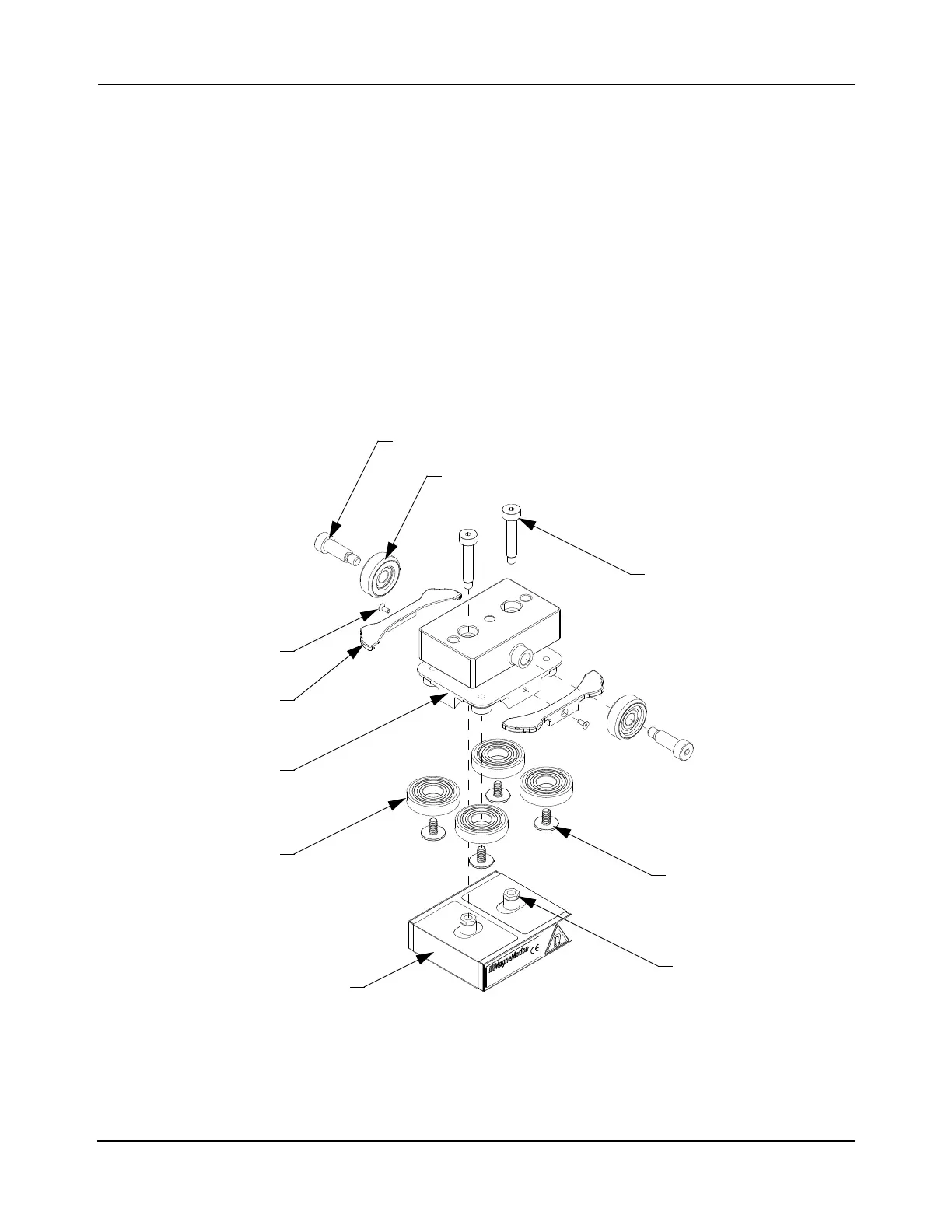

Figure 30: Replace 2-Wheel Puck Wear Points

Required Tools and Equipment

• PN-521984 – Wheel, Payload, Urethane, Core, Puck, Wheeled, ML (2X)

• PN-518836 – Wheel, Lateral Guide, Urethane, Puck, Wheeled, ML (4X)

M4 x 23.5 Shoulder Screw

(2X)

Magnet Array

10-32 Ultra-Low-Profile Shoulder Screw

Suspension (Payload) Wheels

(2X)

(2X)

M2 Screw

(2X)

Bumper

(2X)

Lateral Guide

Wheels (4X)

Puck Body

M4 x 0.7 x 7.5

Screws (4X)

Threaded Standoff

(ref)

Loading...

Loading...