SUPER ELF S3 – Dornier

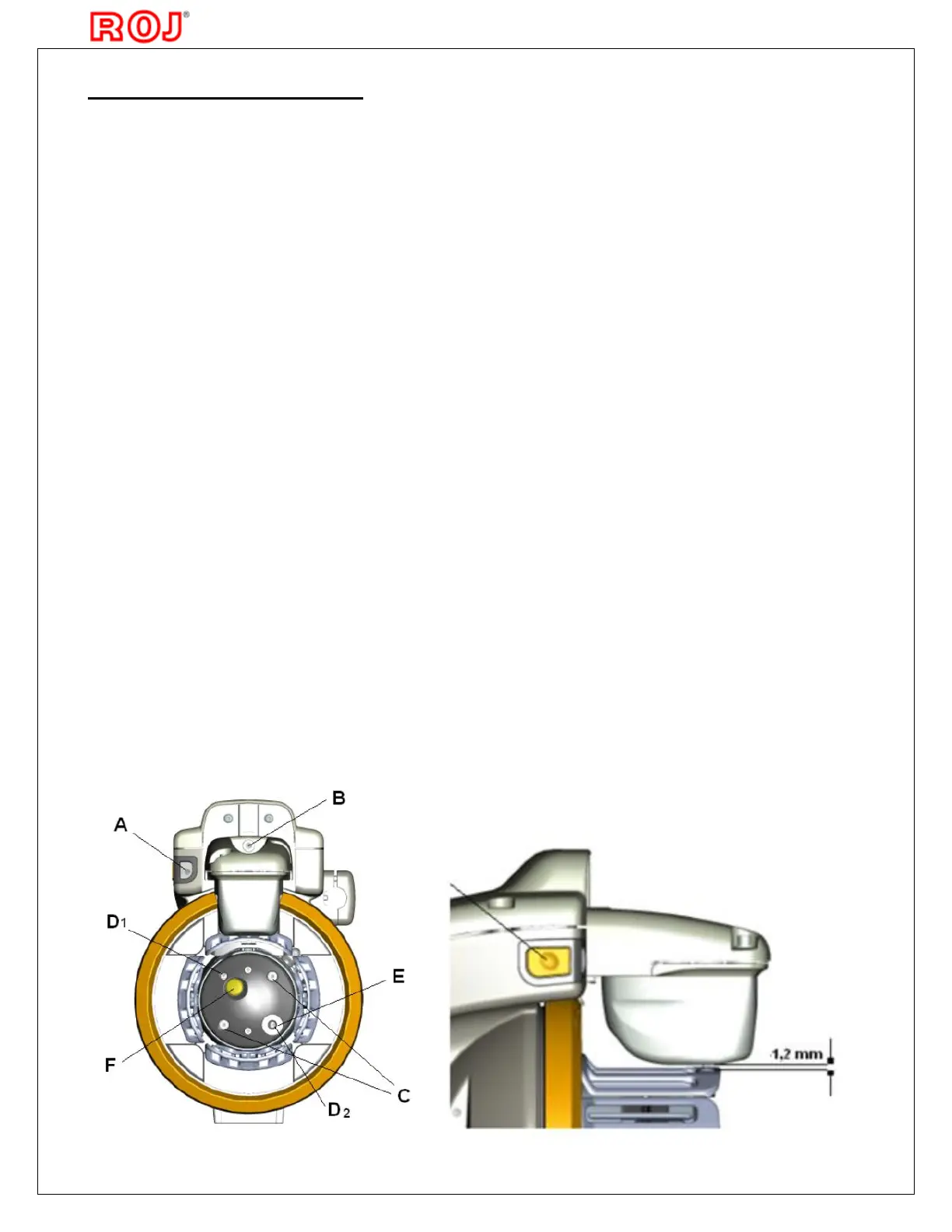

Weft length adjustment

The diameter of the Weft Feeder Spool Body must be set according to the indication shown

on the loom Dialog panel display.

Proceed as follows:

1. Loosen the screw B and raise the Photocells/Electromagnet Group. Fix it.

2. Loosen the both C socket head screws (3 mm socket).

3. Turn the Winding Disc until the eyelet is in the upper position.

4. Loosen the D1 socket head screw (3 mm socket).

5. Turn the Winding Disc until the eyelet is in the lower position.

6. Loosen the D2 socket head screw (3 mm socket)

7. Adjust the diameter of the Spool Body by turning the E socket screw (5 mm socket screw

with the hole for D1 screw) in order to move the sectors of the Winding Group to the

requested reference according to weft length to be inserted (see page 10).

8. Turn the Winding Disc until the eyelet is in the lower position.

9. Tighten the D1 and D2 socket head screws (3 mm socket) to block the fixed sectors

(remember to center the hole on the screw head, points 3 and 5).

10. Check that the movable sectors are centrally positioned in respect with the fixed ones.

11. Tighten the two screws C to block the movable sectors.

12. Turn the Winding Disc and check that no movable sectors get in contact with the fixed

ones; this is in order to avoid possible damages when the feeders is in operation. If the

sectors get in contact, use the C screws to adjust the movable sectors.

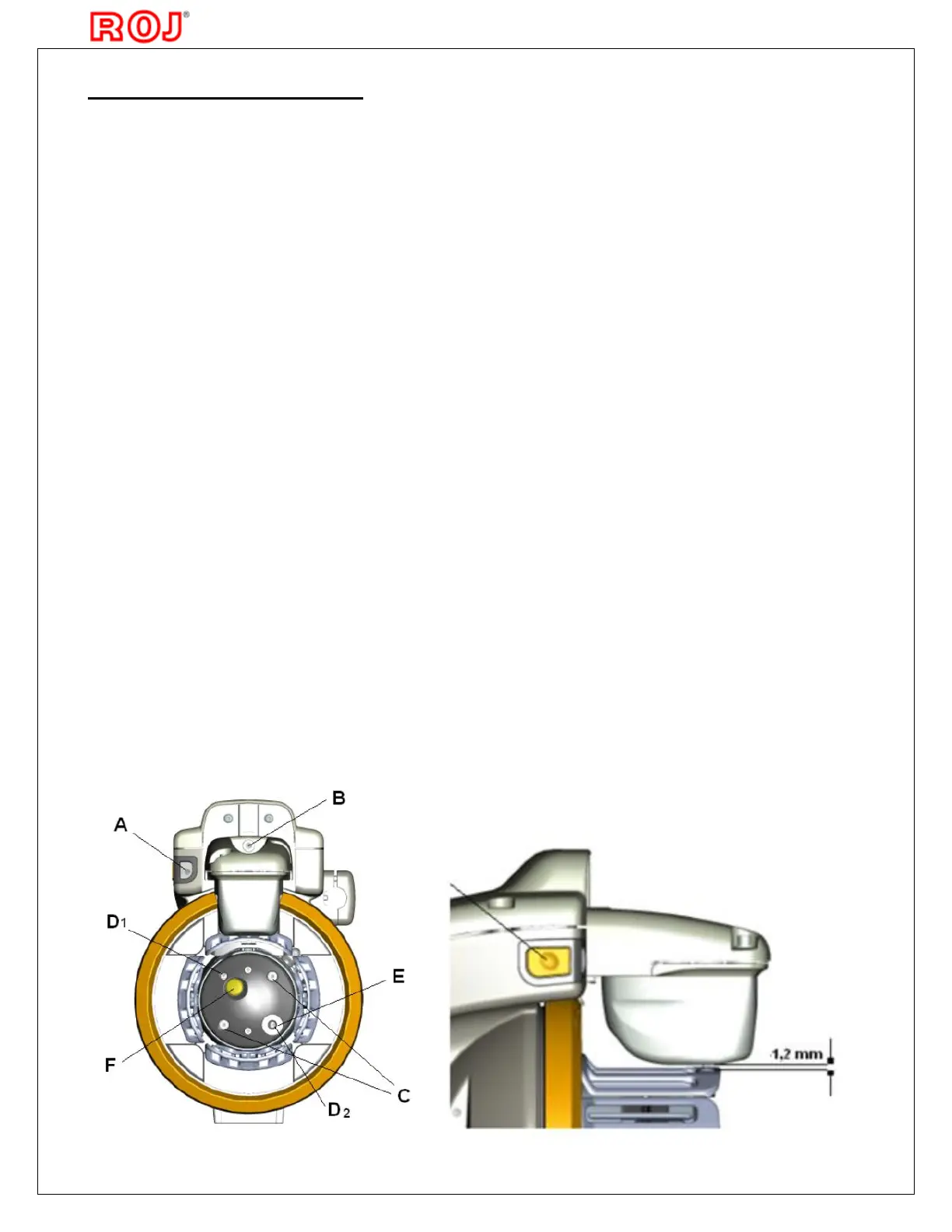

13. Loosen the screw B and position the Photocells/Electromagnet group so that the distance

between the Electromagnet and the Spool Body is about 1-1.2 mm (see picture below on the

right - use the special gauge supplied with the feeder).

14. Load the reserve as described on page 18.

15. Start up the loom and check if the length weft is as required. If it is too long, decrease a bit

the spool body diameter. If it is too short, increase a bit the diameter.

Note: Fixing torque recommended for the screws D1, D2 and C = 2.3 Nm ± 10%

Loading...

Loading...