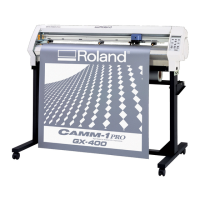

Do you have a question about the Roland Camm-1 PNC-1850 and is the answer not in the manual?

Instructions for proper grounding of equipment and safe operating guidelines.

Includes Canadian Class B notice, general cautions, and user manual disclaimers.

Explanation of symbols used in the manual for warnings, dangers, cautions, and notices.

Comprehensive safety advice covering product modification, handling, environment, and operation.

Instructions regarding specific operational notices found on unit labels, such as pausing cutting.

Notices concerning precision handling, installation environment, voltage, and cable management.

Covers cutting area, blade information, display menu explanations, and plotting.

Includes troubleshooting guides, error messages, and device control instructions.

List of included accessories to verify upon unpacking the unit.

Identification of unit components through front and rear view diagrams.

Step-by-step guide for fundamental operations of the PNC-1850/1200.

Instructions for proper installation, placement, and connection of the unit.

Procedure for installing and replacing the cutting blade and blade holder.

Step-by-step instructions for installing and removing the blade holder.

Diagrams illustrating correct pinch roller placement for different sheet widths.

Detailed steps for loading and preparing rolled sheets for cutting.

Instructions for loading sheets using the sheet base (PNC-1200 only).

Steps for mounting shafts and securing the rolled sheet on the stand.

Aligning the sheet and adjusting pinch roller positions for proper cutting.

Handling control panel messages and menu navigation during sheet loading.

Aligning the flat sheet using guide lines and rollers for straight loading.

Checking for sheet offset and alignment issues during piece scanning.

Securing rolled sheets on shafts and finalizing sheet feed to the carriage.

Using the separate cutter to cut off excess portions of the sheet.

Setting the computer's output port for the chosen interface type.

Selecting interface type and configuring serial communication parameters.

Procedure for performing cutting tests and analyzing results.

Adjusting cutting speed, blade force, and blade compensation parameters.

Procedure for adjusting blade compensation for clean corner cuts.

Specific advice for cutting sheets with strong adhesive layers.

Configuring application software and transferring cutting data.

Procedures for temporarily halting and resuming or aborting cutting operations.

Using the Replot feature to create copies of the same cutting sequence.

Crucial warning about opening the cover during operation to avoid errors.

Instructions for applying the cut-out designs onto surfaces.

Guidelines for cleaning and maintaining the unit.

Instructions for cleaning the body, platen, rollers, and covers.

Specifies the maximum cutting dimensions and acceptable sheet widths.

Information on blade condition, maintenance, and factors affecting its lifespan.

Describes the power on sequence and initial menu navigation steps.

Configuration for automatic sheet feed and cutting distance correction.

Function to repeat cutting sequences and manage the replot buffer.

Procedure to select the type of sheet loaded (Roll, Edge, Piece).

How to set and store cutting parameters like speed, force, and compensation.

Step-by-step guide for adjusting the cutting speed parameter.

Procedure for adjusting blade compensation for clean corner cuts.

Procedure for adjusting the pressure or force of the blade during cutting.

Setting to enable smooth cutting of curves and arcs.

Adjustment for using thicker sheets, affecting speed settings.

Setting the speed for tool movement when raised.

Procedure for setting a user-defined origin point on the sheet.

Rotating the cutting coordinate origin by 90 degrees.

Procedure to feed the sheet to ensure sufficient material for cutting.

Setting display units for length (Metre or Feet).

Configuration for automatic sheet feed at cutting.

Adjustment for distance errors based on actual measurements.

Function to repeat cutting sequences and manage the replot buffer.

Selecting the type of instructions the unit understands (Mode 1, 2, or Auto).

Selecting the connection interface (Parallel, Serial, or Auto).

Configuring serial communication parameters like Stop Bit, Data Bit, Parity, Baud Rate, Handshake.

Setting the size of data blocks and parity check mode for serial communication.

Setting the data transmission speed and handshake mode for serial connections.

Enabling or disabling tool change commands from the computer.

Using VS command for setting cutting speed and FS command for force.

Changing display language and setting coordinate units (Mechanical or Millimeter).

Performing a demo cut for operation check when the unit is not working correctly.

Moving the blade up, down, or in four directions for cutting.

Benefits of plotting for design verification and compatible pen/paper combinations.

Recommended pen speed and force settings, and guidance on pen replacement.

Step-by-step instructions for performing plotting operations.

Matching plotter settings to software pen configurations for pen change operations.

A systematic checklist for troubleshooting common issues with the PNC-1850/1200.

Steps to diagnose and resolve power-on and connectivity problems.

Troubleshooting specific messages related to pinch rollers and the front cover.

Troubleshooting motor errors and power-related issues.

Checking blade installation security and condition for proper cutting.

Diagnosing and resolving issues related to sheet slippage during the cutting process.

A list and explanation of error messages displayed by the unit.

List of optional accessories available for the PNC-1850/1200.

Details on the unit's mechanical components and cutting speed specifications.

Specifications for interfaces, dimensions, weight, temperature, and humidity.

Pin connection details and signal specifications for the parallel interface.

Pin connection details and signal specifications for the serial interface.

Instructions for handshake protocols and DTR signal control.

Instructions for outputting buffer status, pause state, and RS-232C error codes.

Commands to abort device control, CAMM-GL III instructions, and initialize settings.

| Drive Method | Servo motor |

|---|---|

| Resolution | 0.025 mm |

| Media Thickness | 0.1-1.0 mm |

| Repeatability | ±0.1 mm |

| Power Requirements | 100-240 V, 50/60 Hz |