19

MECHANICAL SEAL

Mechanical seals do not require adjustments. Leakage developed at the seal may be due to one

of the following conditions; worn, marred, or cracked rotating or stationary lapped seal faces, or

bellows that has become hard, soft, cracked, expanded or extruded.

When replacing or servicing a mechanical seal, take particular care not to mar or scratch the

sealing surfaces or damage the bellows. If the seal has been used, do not put it back into service

unless both sealing surfaces are perfectly flat and smooth or else replaced.

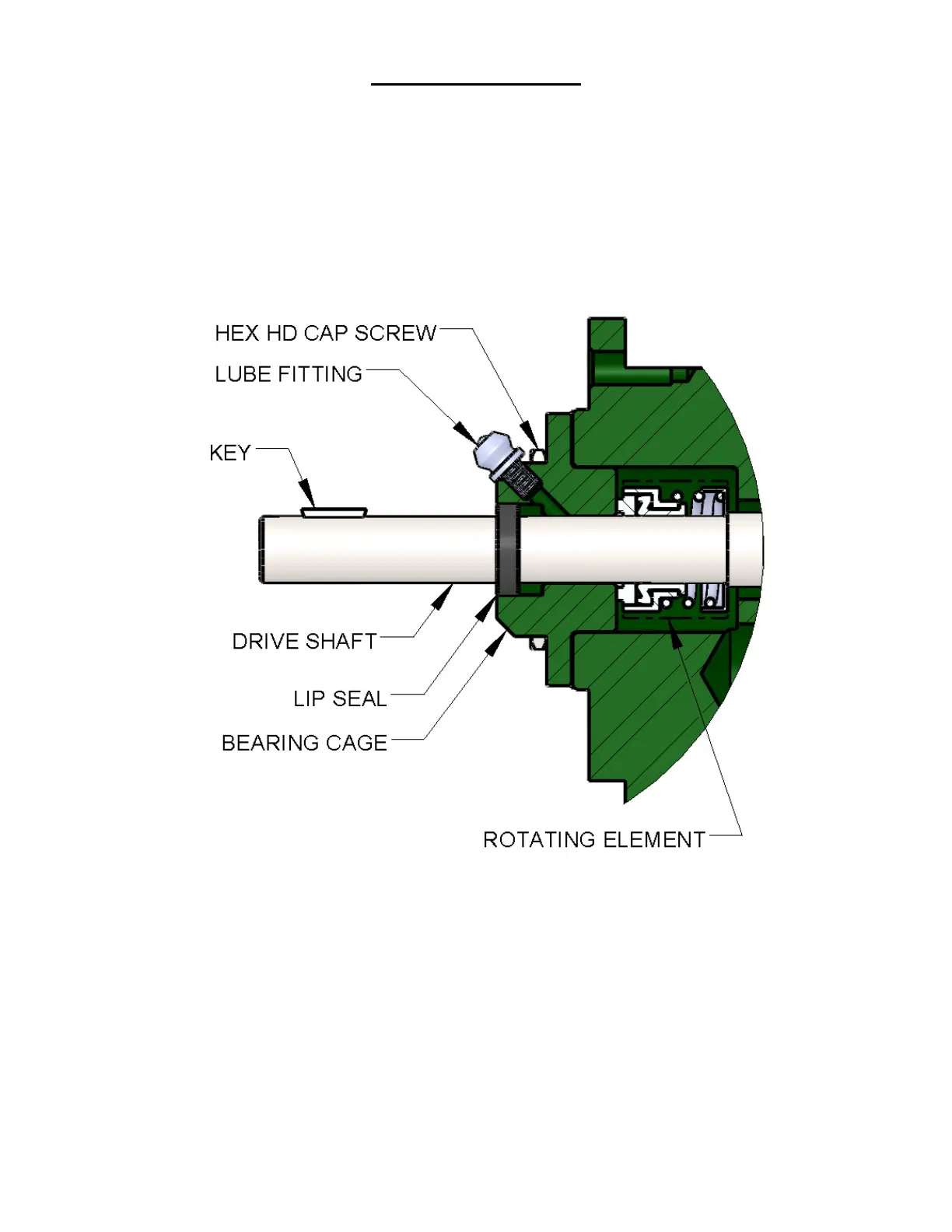

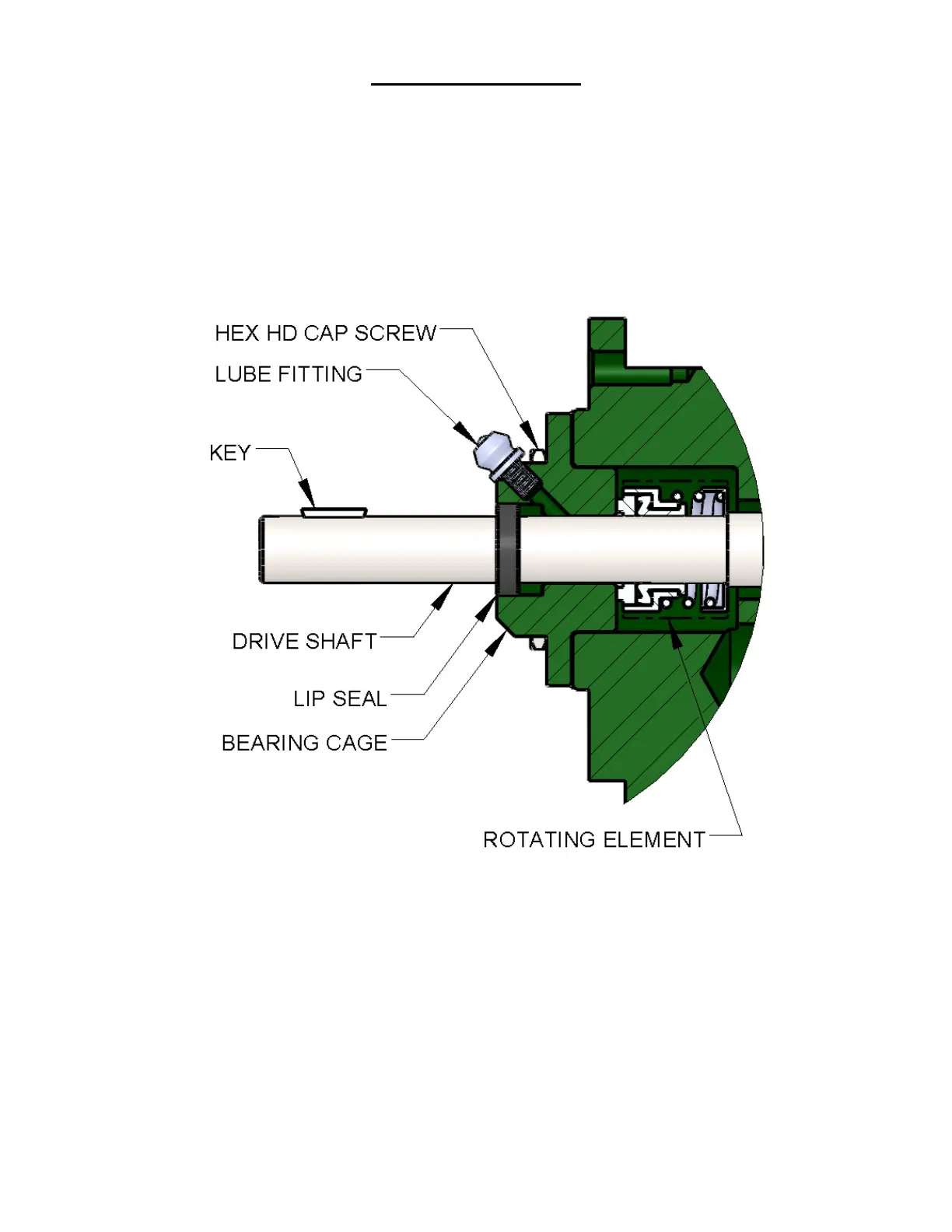

To replace the mechanical seal on pump size F1 thru F5, remove the key, cap screws, bearing

cage, and gasket. Remove burrs and sharp edges from the end of shaft and keyway and clean

the shaft. Next the seal parts may be removed from the shaft. To assemble, lubricate with a light

machine oil the section of the shaft over which the seal is to be mounted. Slide the rotating

element onto the shaft. Be sure it is properly centered on the shaft. After checking the bearing

cage and lip seal and replacing if required, coat the sealing surfaces with light machine oil. Install

bearing cage and gasket and secure with the cap screws.

Loading...

Loading...