4

NOTICE: These are general guidelines and do not cover all possible situations. It is the

responsibility of the system integrator to apply this product properly.

System Pressure & Hazardous Fluids

1. Disconnecting fluid or pressure containment components during pump operation can cause property damage,

serious personal injury, or death.

2. Failure to relieve system pressure prior to performing pump service or maintenance can cause property

damage, serious personal injury or death.

3. If pumping hazardous or toxic fluids, system must be flushed and decontaminated, inside and out, prior to

performing service or maintenance.

Plumbing

1. The inlet pipe should be as short and straight as possible to minimize suction pressure losses. Excessive

restrictions at the inlet can cause cavitation resulting in poor performance, noise, vibration, or pump damage.

2. Slope the inlet plumbing appropriately to avoid air pockets.

3. Plumbing weight, misalignment with the ports or thermal expansion can exert excessive force on the pump.

Plumbing must be properly supported and aligned with expansion joints, if required, to minimize these forces.

4. To prevent over pressure situations, install a relief valve as close to the pump outlet as possible. Install the

relief valve before any shut-off valves.

DO NOT use Thread Seal (Teflon

®

) tape on pump port threads.

Mounting Base

1. Mount the unit on a rigid, heavy base to provide support and absorb shock. Bases should be designed for

high rigidity; not just strength.

2. The pump feet were not designed for mounting to concrete and do not have enough contact area to prevent

concrete from failing. When mounting to cement or concrete, use a steel baseplate to distribute the mounting

stress over an area large enough to prevent the cement from failing. Grout it in place.

Pump and Drive Assemblies

1. Assure adequate guards have been installed to prevent personnel contacting moving components.

2. Follow all OSHA, Federal, State, and local codes.

Check Alignment of Pump to Driveline

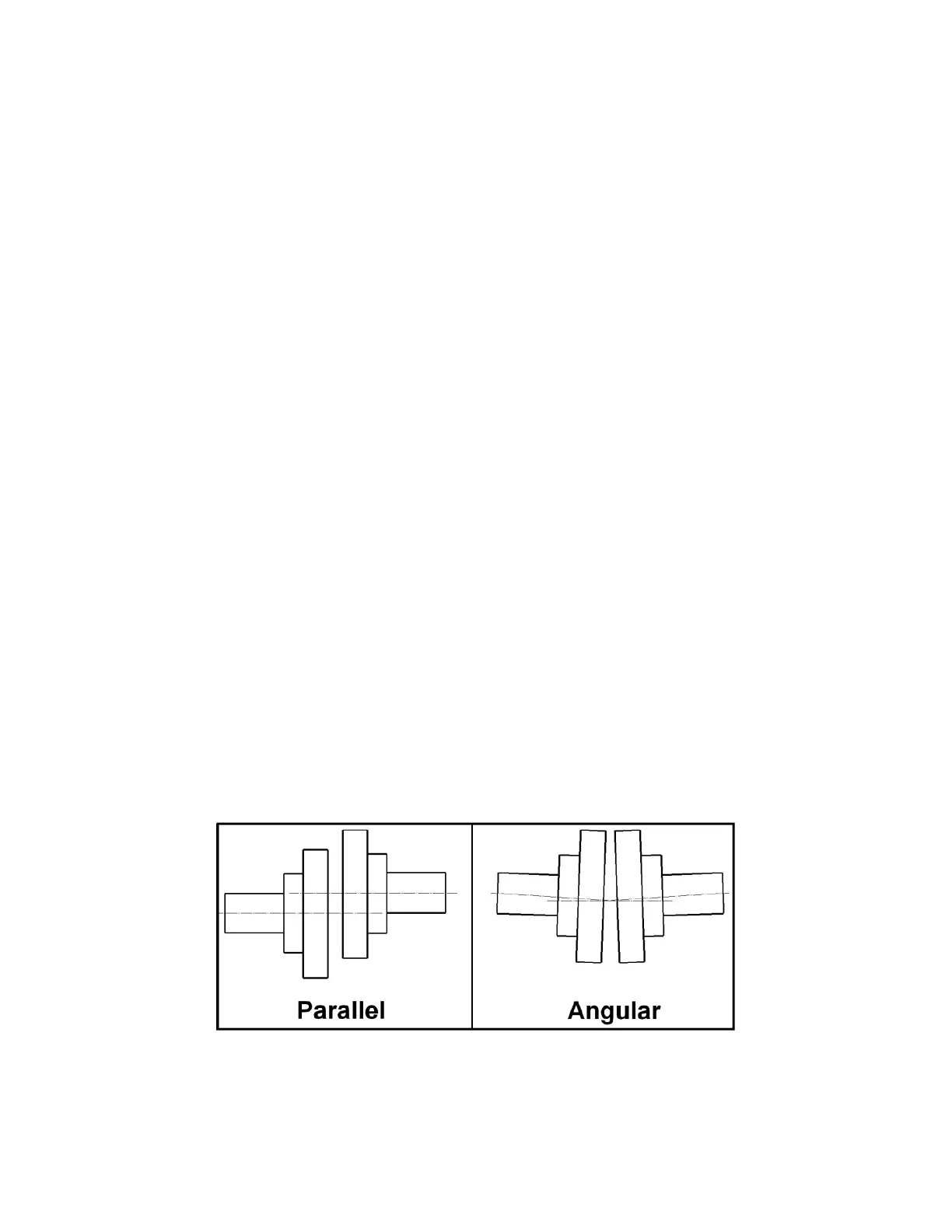

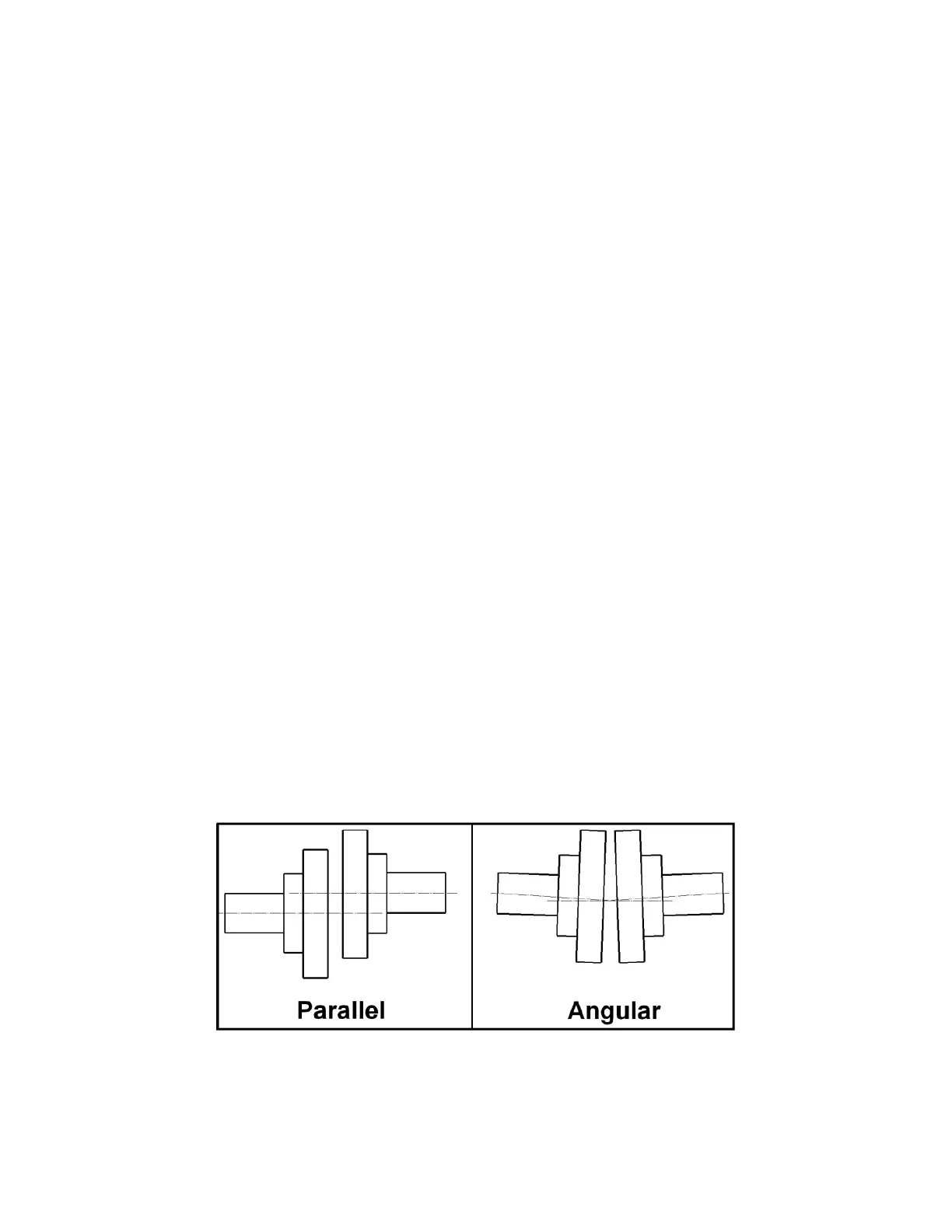

Excessive misalignment can overload the pump input shaft and cause premature failure. The figures below show

parallel and angular misalignments.

Figure 1-1: Coupling Alignment

Teflon® is a registered trademark of E.I. DuPont de Nemours Co., Inc.

Loading...

Loading...