Model 1199 Diaphragm Seal Systems Manual

2-2

Tagging

Each diaphragm seal system is tagged in accordance with the customer

requirements. The standard tag is attached to the transmitter/seal

system. Tag is 0.020 in. (0.051cm) thick with 0.125 in. (0.318 cm) high

letters. A sample tag is shown below. 3-A

®

approved sanitary seal

systems have a 3-A symbol marked on the diaphragm seal.

The Maximum Working Pressure (MWP) of the transmitter/seal system

is stamped on the transmitter neck tag. This is dependent upon the

maximum pressure rating of the seal system or transmitter upper

range limit.

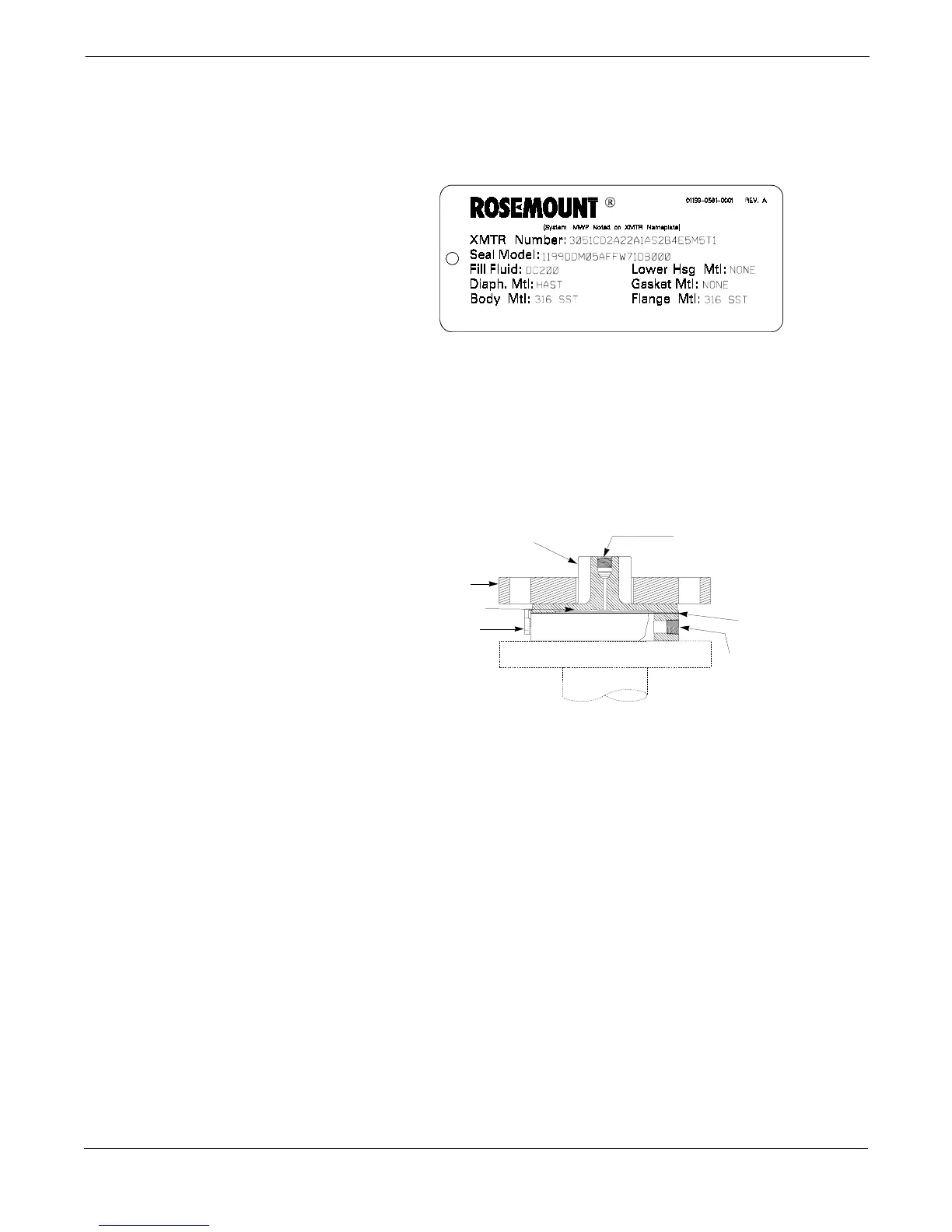

Flanged Type Seals: Flush

or Extended Diaphragm

FIGURE 2-1. Flanged Type Seal.

Bolt Torquing When connecting the process and mating flange, the bolts should be

torqued to the applicable flange requirements. Required torque is a

function of the gasket material and surface treatment of the bolts and

nuts which are customer supplied.

Flushing Connection Ring

Installation

The flanged type seals are available with an optional flushing

connection ring (or lower housing.) For certain seal types the flushing

connection ring is supplied with four clips and screws that hold the

diaphragm seal to the lower housing in order to make installation

easier.

Gasket Installation When connecting the diaphragm seal, gasket, and flushing connection

ring make sure the gasket is properly aligned on the gasket sealing

surface.

Mounting

Flange

Upper Housing

Capillary Connection

Diaphragm

Flushing Connection

Ring (Lower Housing)

Gasket

Process Side

Mounting Clip

3051A23C

1199-0561A01A

Loading...

Loading...