3-5

Calibration

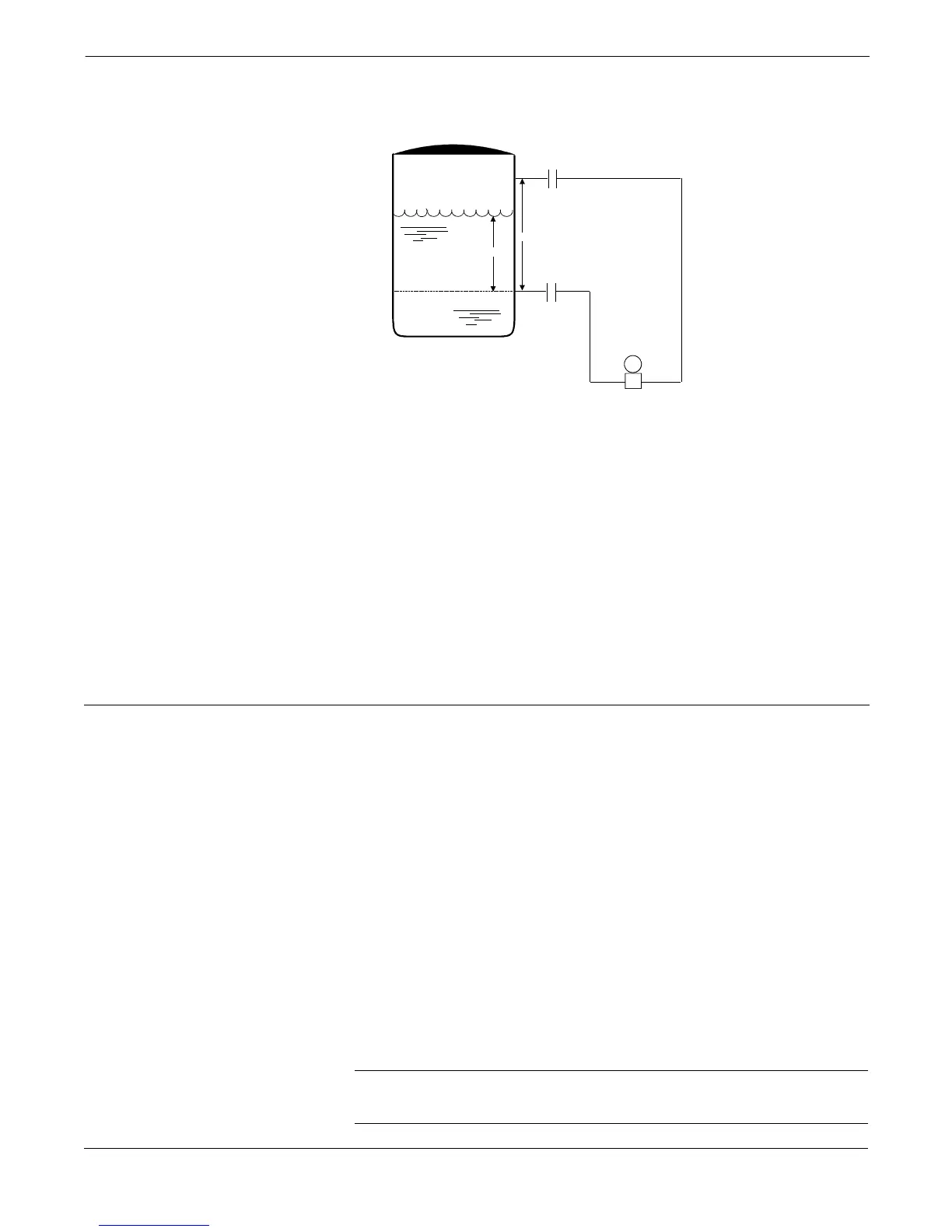

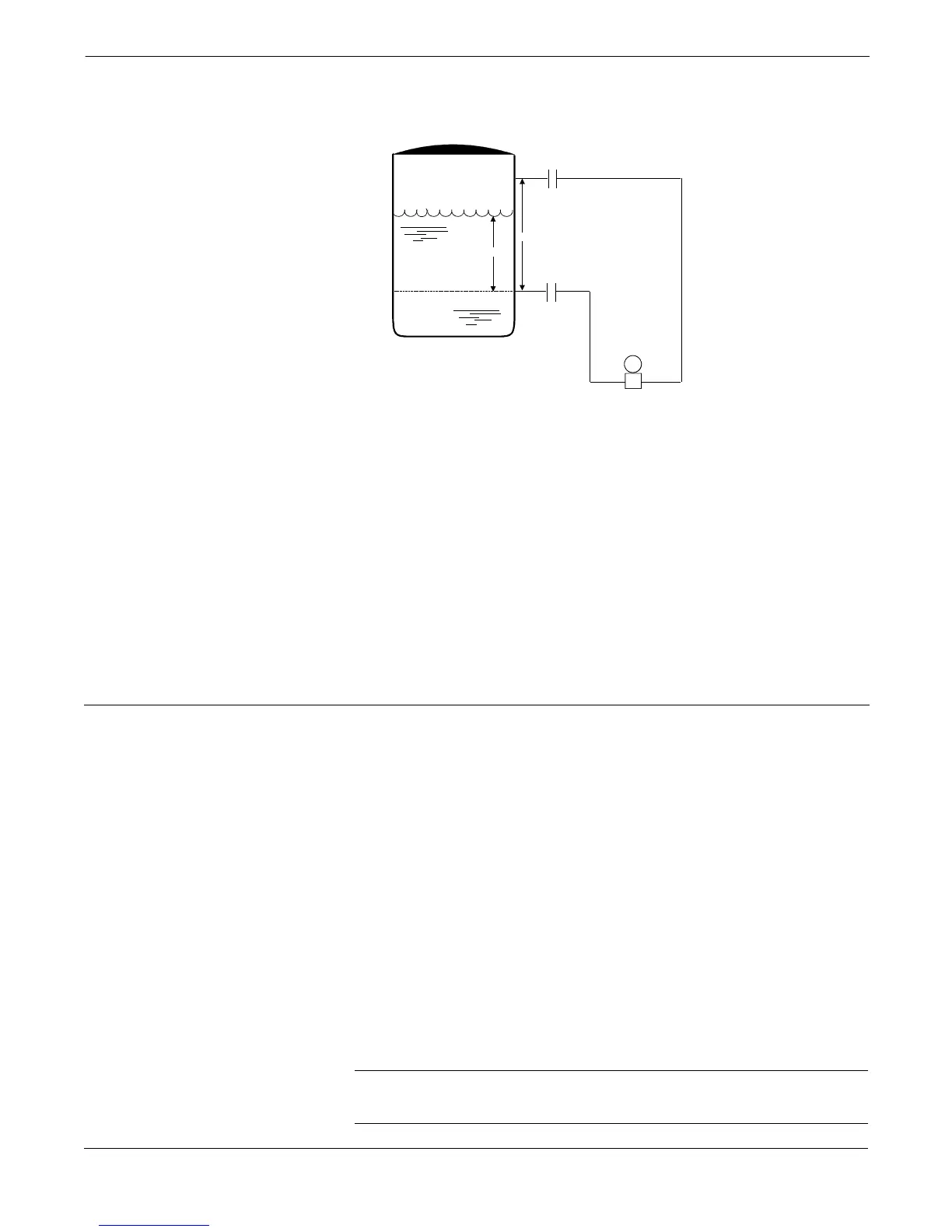

FIGURE 3-3. Transmitter with Two-Seal System.

American Units 1. Calculate the amount of zero elevation by multiplying the

distance between the process connections (h) by the specific

gravity of the fill fluid (s

f

).

Zero Elevation = -(h)(s

f

)

= - (400 inches) (1.07 inH

2

O/inch) = - 428 inH

2

O

2. Calculate the span by multiplying the maximum height of the

process fluid (H) by the specific gravity of the process liquid (s

p

).

Span = (H)(s

p

)

= (350 inches) (0.9 inH

2

O/inch) = 315 inH

2

O

3. Calibrate the transmitter using the following equation:

Calibration = Zero Elevation to (Zero Elevation + Span)

= - 428 inH

2

O to (- 428 + 315 inH

2

O)

= - 428 inH

2

O to - 113 inH

2

O.

SI Units

Calibration:

Summary In this example a Model 3051CD Range 3, URL = 1,000 inH

2

O

(2,5 bar) or a Model 1151DP Range 5, URL = 750 inH

2

O

(1,9 bar) transmitter is required.

NOTE

Calibrating a Two-Seal System With Elevated Zero

(Transmitter Mounted Level With, Above, or Below the High Pressure Tap)

Given:

DC 704 fill fluid

(S

f

) = 1.07 in H

2

O/inch

(-h) = - 400 inches

(S

p

) = 0.9 in H

2

O/inch

(H) = 350 inches

H

1199-0160L

h

Transmitter

Given:

High Temperature

Silicone Oil fill fluid

(ρ

f

) = 1 070 kg/m

3

(-h) = -10 meters

(ρ

p

) = 900 kg/m

3

(H) = 8,5 meters

(g) = 9,81 m/s

2

Zero Elevation ρ

f

gh⋅⋅–=

1070–=981,

10

100

---------

mbar⋅⋅

– mbar=

Span ρ

p

=gH⋅⋅

900= 981,

85,

100

---------

mbar⋅⋅

750 mbar=

4mA Zero Elevation

mbar–==

20mA Zero Elevation Span+

750 mbar+–==

mbar–=

1mbar

100

-----------------------1kgm

3

⁄()1m s

2

⁄()1m()⋅⋅1N m

2

⁄==

Step 1

Step 2

Step 3

Step 1

Step 2

Step 3

Step 4

Loading...

Loading...