4

4‑3

HYDRAULIC SYSTEM OIL LEVEL

OL1D-SM-GB02D

4.1 To check hydraulic system oil level

WARNING:

THE BODY MUST BE EMPTY WHEN

CHECKING THE HYDRAULIC SYSTEM OIL

LEVEL.

The level is checked with:

• Tailgate fully lowered (cylinders open).

• The ejection plate fully ejected to the rear of

the body (cylinder open).

• The compaction mechanism packer plate

is open and carriage plate is fully lowered

(cylinders closed).

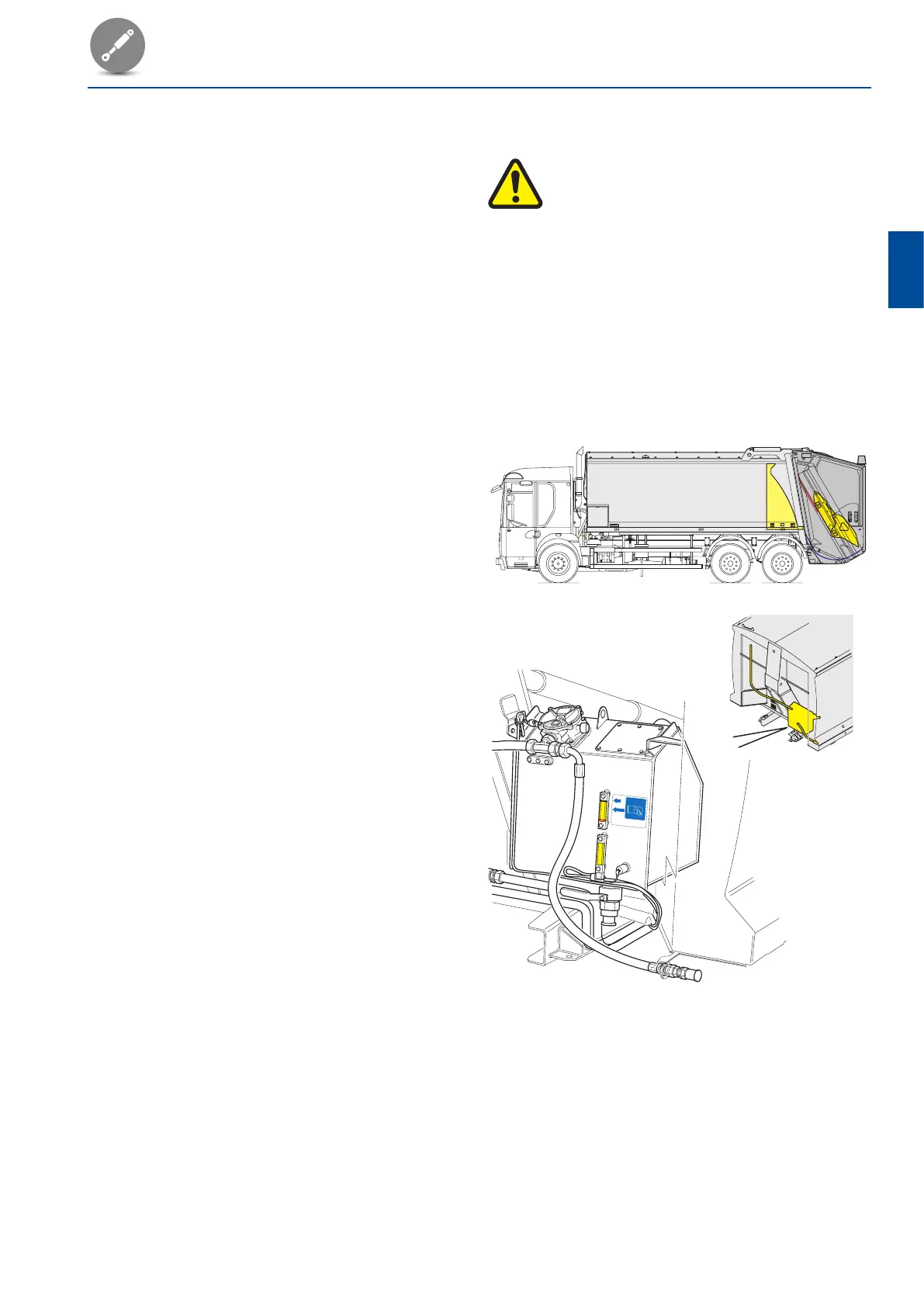

This is shown on the label adjacent to the hydraulic oil

level gauge.

Hydraulic Oil

Max.

CLEAN UP ALL SPILLAGES

PT. No. 1001996

ONLY USE CLEAN OIL OF THE

CORRECT SPECIFICATION

MAX.

O

L

2

5+27 O

N

L

Y

Procedure

1. Stand the vehicle on clean, level and stable ground

with sufficient clearance to allow for the tailgates

to be fully raised.

2. Engage the parking brakes.

3. Select Neutral ‘N’.

4. Check that the tailgate is in the normal position

locked to the body.

5. Make sure that all personnel are clear of the body,

tailgate and rear of the vehicle.

4 Hydraulic system oil level

It is most important that the level of fluid in the

hydraulic reservoir is maintained within the specified

limits.

Topping up of the oil must be conducted in a

controlled workshop environment using a pressurised

filling system connected to a quick release coupling

on the system. Operator’s without a bulk oil delivery

system are supplied with an optional hand pump and

hoses.

It is most important that the hydraulic system is

maintained according to Dennis Eagle Limited

Maintenance Schedule and associated instructions.

System maintenance and filter element change

requirements are specified in Chapter 6 ‘Scheduled

maintenance’ of this Manual.

Loading...

Loading...