4

4‑7

HYDRAULIC SYSTEM OIL LEVEL

OL1D-SM-GB02D

4.1.1 Topping up hydraulic oil

- bulk oil supply

1. If topping up is necessary, thoroughly clean:

• The quick release coupling cap and its

surrounding area.

• Any filling equipment to be used.

855370

Stop engine

before entering

HYDRAULIC OIL

ONLY

Hydraulic Oil

Max.

CLEAN UP A

L

L

SPILLAG

E

S

P

T. No. 1001996

ONL

Y

USE

CLEAN OIL

OF THE

CORRECT SPECIFI

CAT

ION

MAX

. OL

2

5

+27

ON

LY

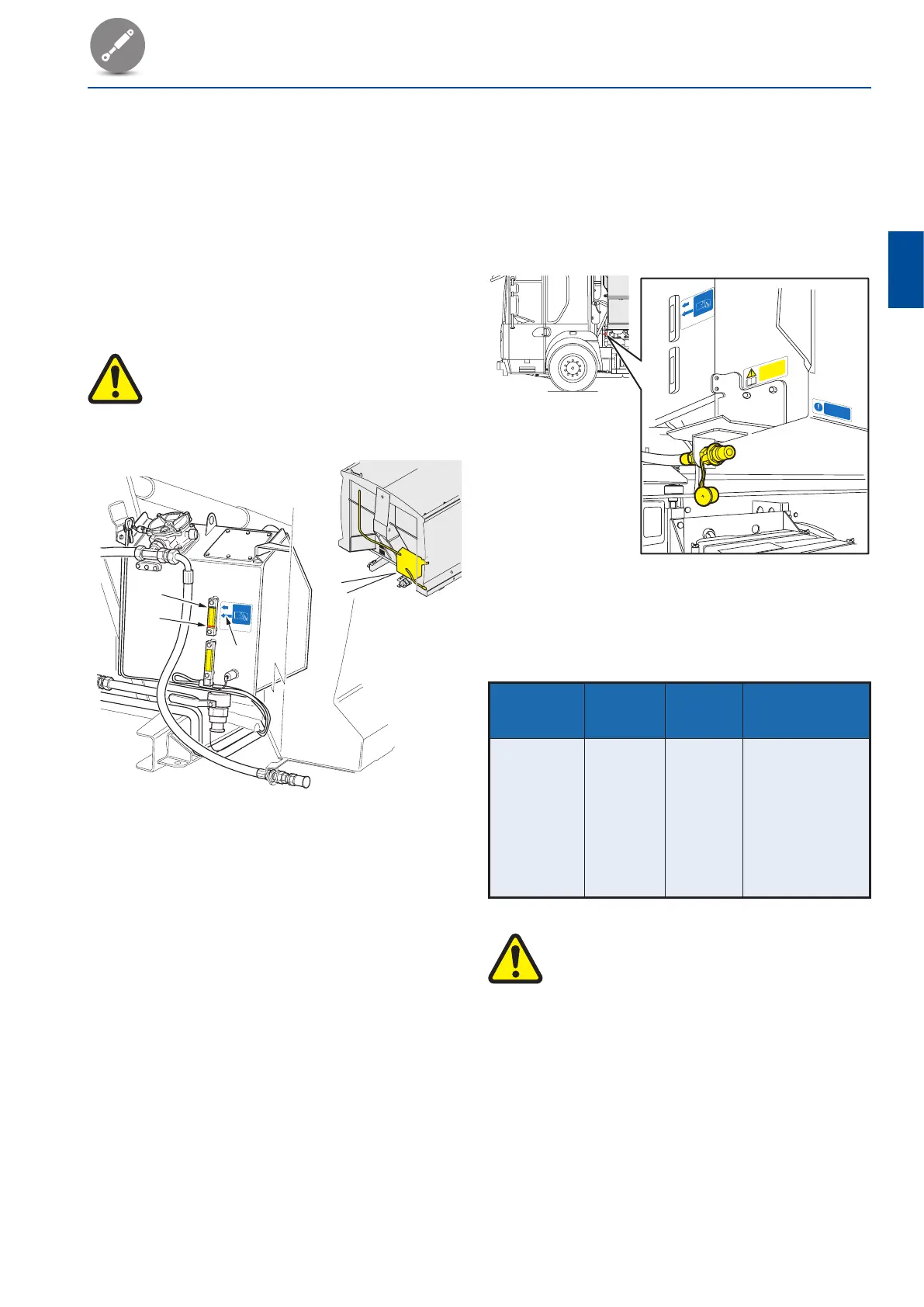

Fig. 4-2 Quick release coupling

2. Connect the filling equipment to the quick release

coupling (see Fig. 4‑2). Top up as necessary to the

correct level using new hydraulic oil to the correct

specification.

Temperature

Range

BS 4231

Viscosity

Grade

ISO Oil

Type

Manufacturers

Specification

‑30° to +80° 32 HM Q8 Foil 32

BLP

Note: Q8 Foil

32 used on new

equipment.

Biodegradeable

viscosity 46 oil is

used where

specified

by customers.

Caution:

Do not mix different oil types.

3. Disconnect the filling equipment from the quick

release coupling.

4. Replace the quick release coupling cap.

5. If the hydraulic level is very low, inspect all the

hydraulic systems including bin lifts, if fitted,

for hydraulic oil leaks. Rectify any leaks before

operating the vehicle.

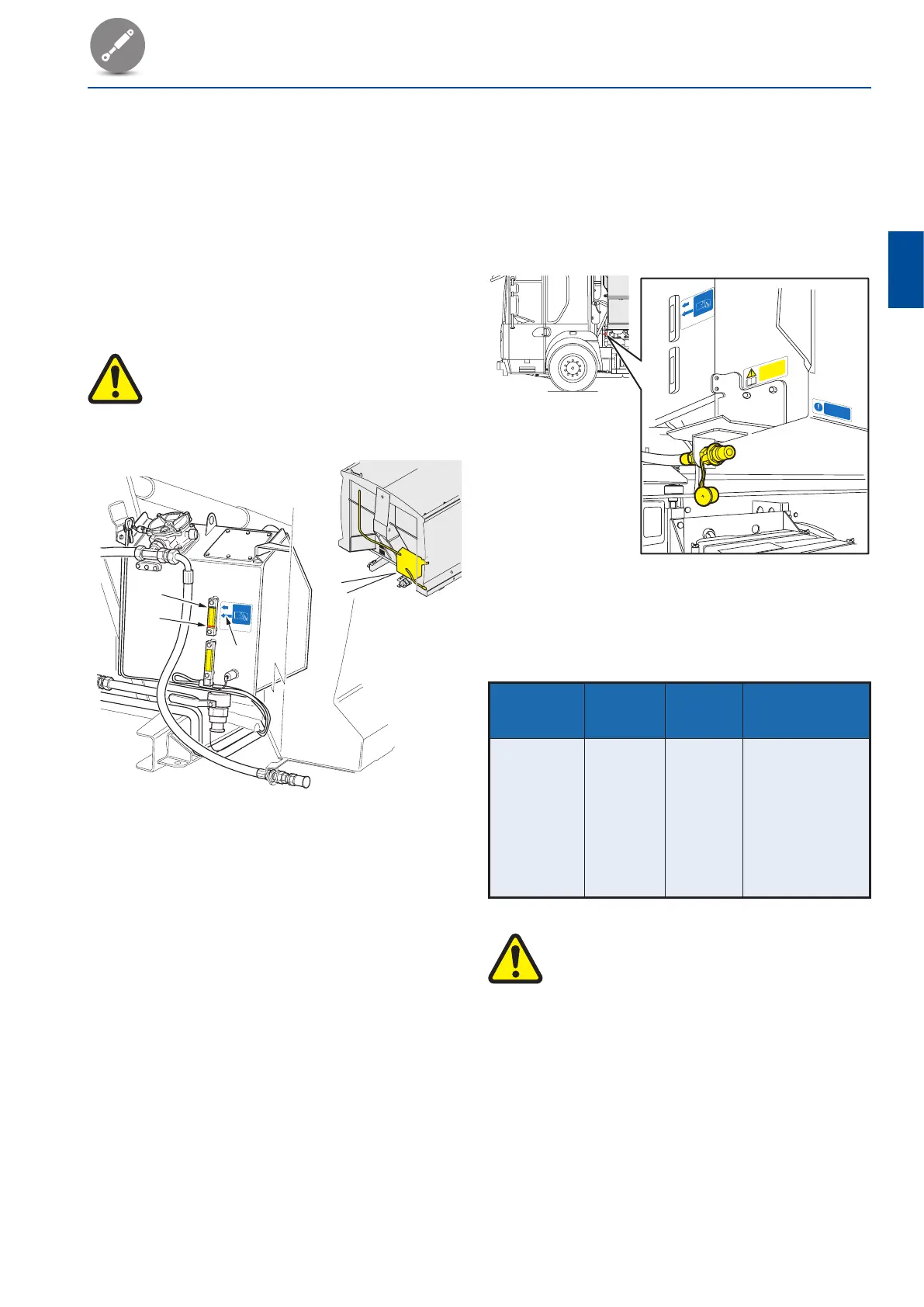

19. Check the oil level.

• The reservoir is fitted with two oil sight glasses.

The upper glass is marked with black and red

lines to show maximum (see Fig. 4‑1, A) and

minimum (see Fig. 4‑1, B) levels respectively

during normal operation.

• When the compaction mechanism packer plate

is open and carriage plate is fully lowered and

the ejection plate to the rear of the body, the

level should align with the point of the arrow

corresponding to the body size (see Fig. 4‑1, C)

on the label adjacent to the upper glass.

Caution:

If the oil level is only visible in the

lower sight glass, the hydraulic system

must not be used until the system has

been filled to the correct level.

Hydraulic Oil

Max.

CLEAN UP ALL SPILLAGES

P

T.

No.

1001996

ONLY USE CLE

AN OIL OF THE

CORRECT SPECIFICATION

M

A

X

.

O

L

25+

27

O

NLY

A

B

C

Fig. 4-1 Hydraulic oil level

Loading...

Loading...