6

On one bolt, place

(2)5/16" Star Washers

Push nuts hold bolts to brackets.

Fill Breather Cap

Use (4)5/16"-18NC

x1-1/2" lg. HHCS

and Nuts

CAPACITY

9,000 LBS.

For SPOA9/SPO9

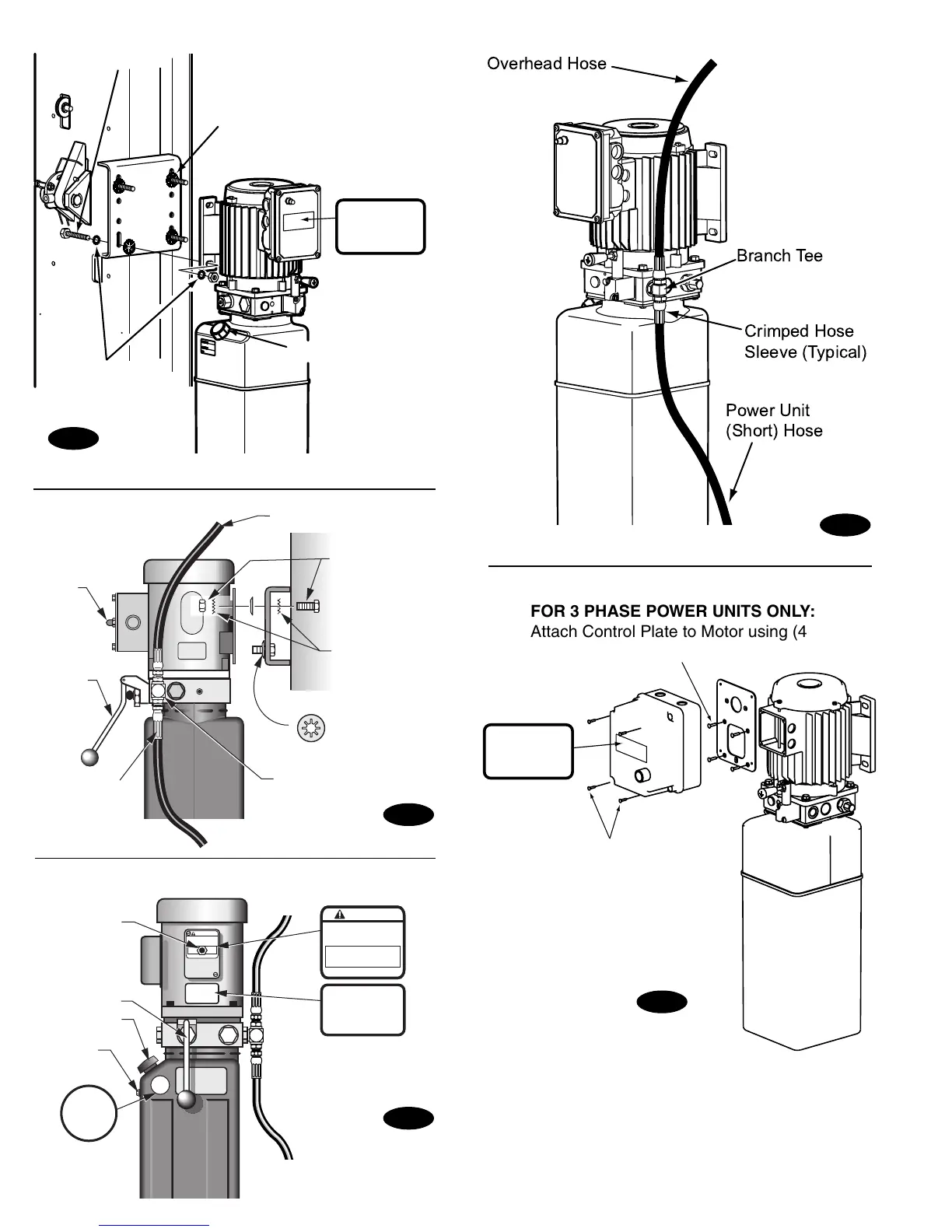

10. Hoses: Clean adapters and hose. Inspect all threads

for damage and hose ends to be sure they are crimped,

Fig. 8a or Fig. 8b. Install hose and hose clamps, Fig. 9b.

HYDRAULIC POWER UNIT

FILLINSTRUCTIONS: Lower lift. Removefill cap

andsocket headvent plug.Fillto vent holewith clean

DexronII ATF

ForParts & Service contact:(800) 445-5438

ROTARYLIFT / ADOVER INDUSTRIESCO.

PUSH

LEVER

TO

LOWER

CAPACITY

7000 LBS.

ALLOW 2 SECONDS

BETWEEN MOTOR STARTS

FAILURE TOCOMPLY MAY

CAUSE MOTORBURNOUT

PUSH BUTTON TO RAISE

NOTICE

Fill-Vent

Screw

Fill-Breather

Cap

Raise

Switch

Lowering

Valve

PUSH

LEVER

TO

LOWER

Branch

Tee

Power Unit

Hose

Overhead

Hose

ALLOW 2 SECONDS

BETWEEN MOTOR STARTS

FAILURE TO COMPLY MAY

CAUSE MOTOR BURNOUT

PUSH BUTTON TO RAISE

NOTICE

ALLOW 2 SECONDS

BETWEEN MOTOR STARTS

FAILURE TO COMPLY MAY

CAUSE MOTOR BURNOUT

PUSH BUTTON TO RAISE

NOTICE

CAPACITY

7,000 LBS.

NP241

For SPOA7

Lowering

Valve

Push-nuts

hold bolts

to bracket.

Use (4) 5/16"-18NC

x 1-1/2" HHCS, and

5/16"-18NC Nuts

On one bolt,

place 5/16"

Star Washers.

Overhead Hose

Branch Tee

Raise

Switch

Lowering

Valve

Crimped Hose

Sleeve(typical)

Overhead Hose

Power Unit

(Short) Hose

Crimped Hose

Sleeve (Typical)

Branch Tee

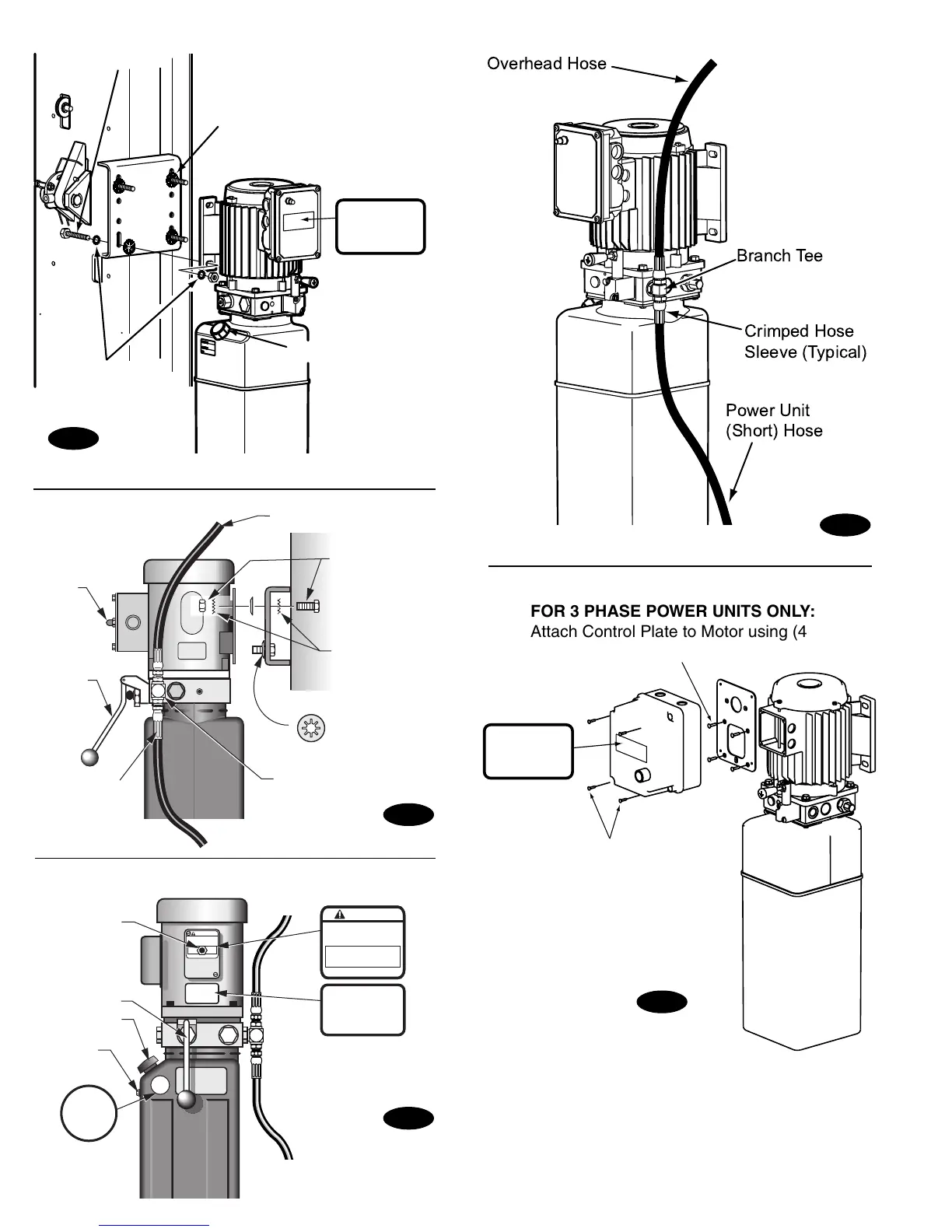

FOR 3 PHASE POWER UNITS ONLY:

Attach Control Plate to Motor using (4)

5mm-.80 x 8mm lg. Flat Head Machine Screws

Attach control box to plate

using (4) #8-32NC x 1/2"

Self-Tapping Slotted PHMS

CAPACITY

9,000 LBS.

For SPOA9/SPO9

Fig. 7a

Fig. 8a

Fig. 7b

Fig. 8b

Fig. 8c

Loading...

Loading...