1

2

ON

1

2

ON

1

2

ON

1

2

ON

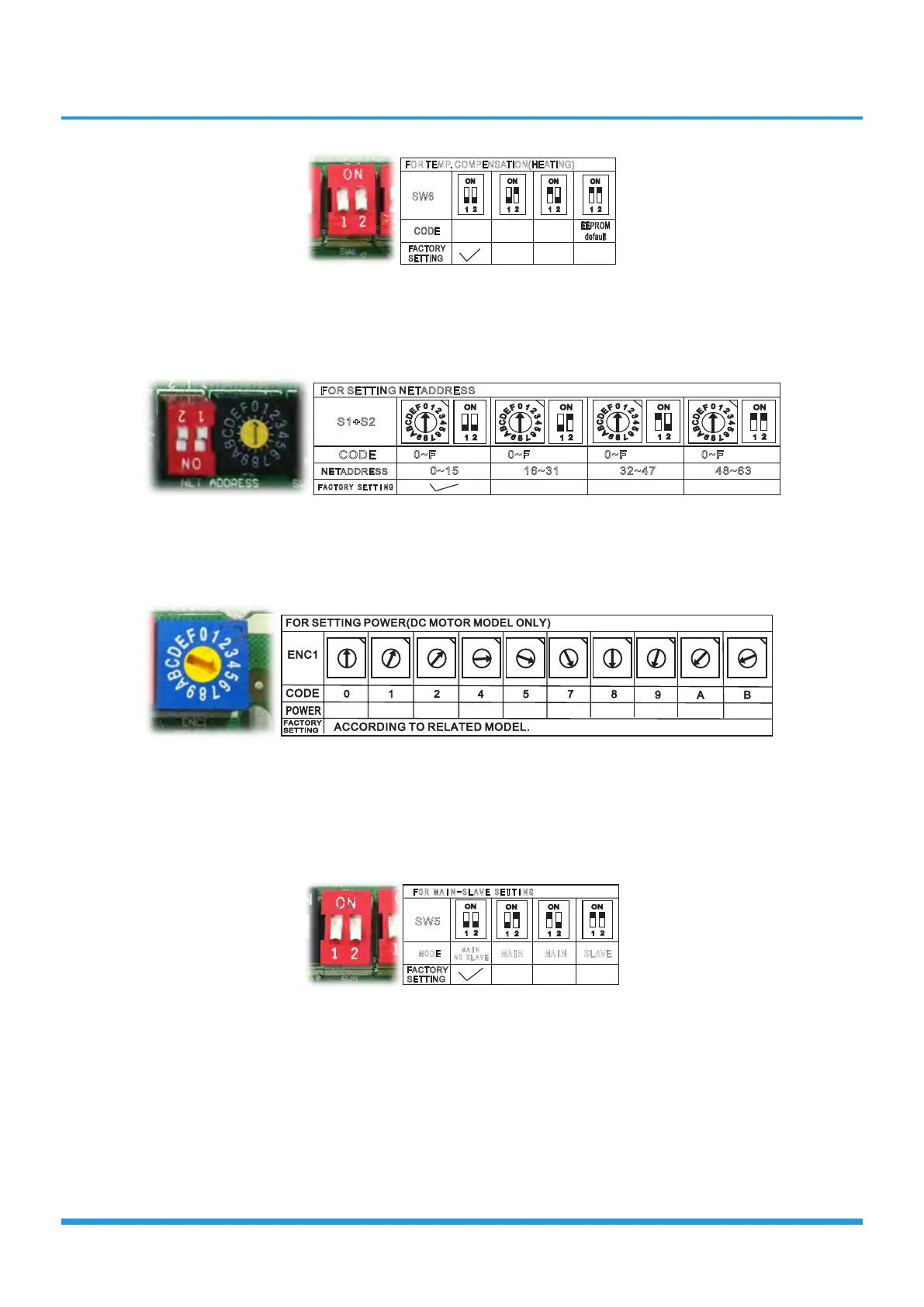

SW6

CODE

0℃

FORTEMP. COMPENSATION(HEATING)

2℃ 4℃

FACTORY

SETTING

EEPROM

default

D. Micro-switch SW6 is for selection of temperature compensation in heating mode. This helps to reduce the real

temperature difference between ceiling and floor so that the unit could run properly. If the height of installation is lower,

smaller value could be chosen.

Range: 6°C, 4°C, 2°C, E function (reserved for special customizing)

0

8

4

1

2

3

5

6

7

C

9

A

B

D

E

F

1

2

ON

0

8

4

1

2

3

5

6

7

C

9

A

B

D

E

F

1

2

ON

0

8

4

1

2

3

5

6

7

C

9

A

B

D

E

F

1

2

ON

0

8

4

1

2

3

5

6

7

C

9

A

B

D

E

F

1

2

ON

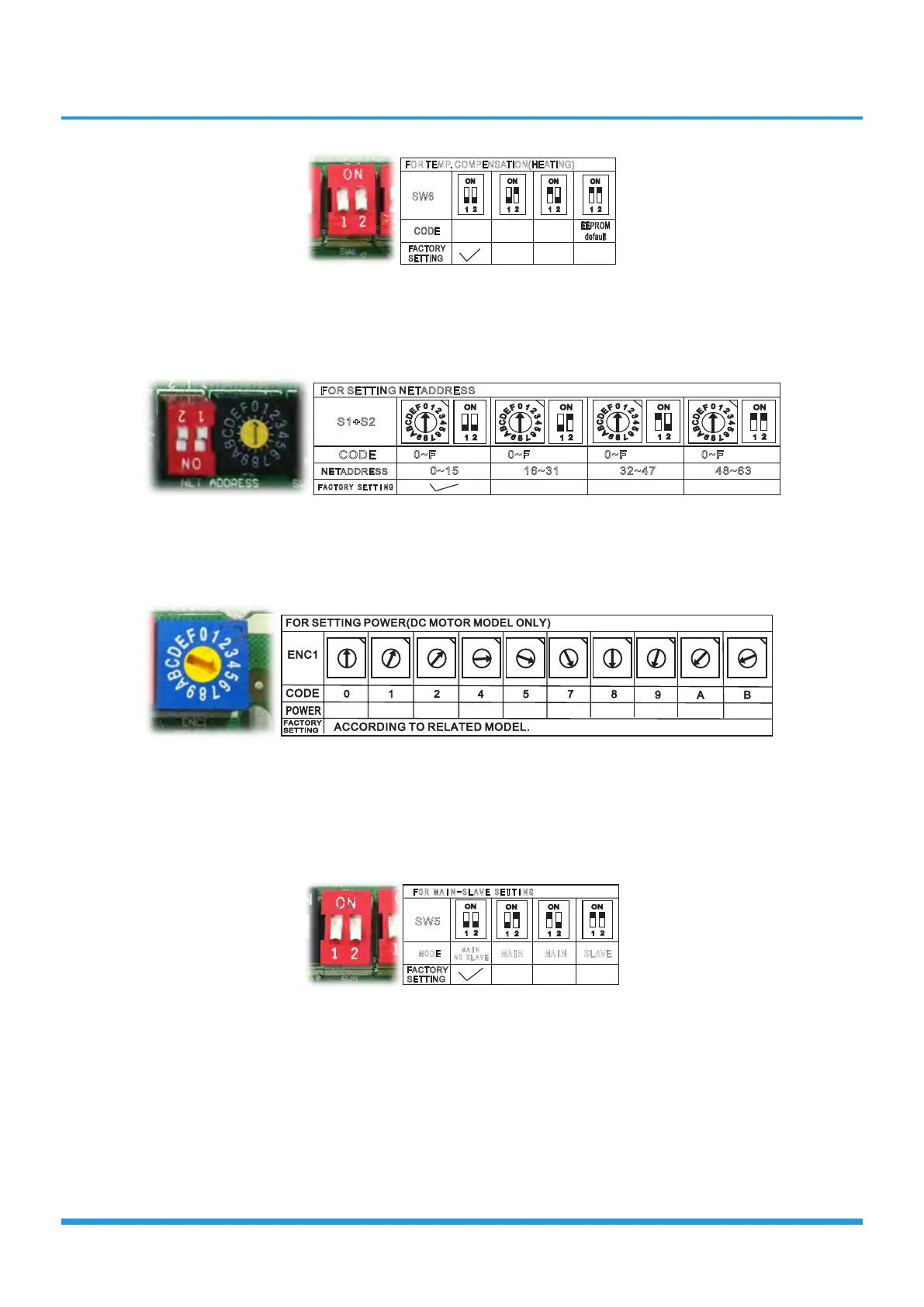

S1+S2

0~F

0~F

0~F

0~F

NETADDRESS

CODE

0~15

16~31

32~47

48~63

FACTORY SETTING

FOR SETTING NETADDRESS

E. Micro-switch S1 and dial-switch S2 are for address setting when you want to control this unit by a central controller.

Range: 00-63

106~140

161~200

0

8

4

1

2

3

5

6

7

C

9

A

B

D

E

F

0

8

4

1

2

3

5

6

7

C

9

A

B

D

E

F

0

8

4

1

2

3

5

6

7

C

9

A

B

D

E

F

0

8

4

1

2

3

5

6

7

C

9

A

B

D

E

F

0

8

4

1

2

3

5

6

7

C

9

A

B

D

E

F

0

8

4

1

2

3

5

6

7

C

9

A

B

D

E

F

0

8

4

1

2

3

5

6

7

C

9

A

B

D

E

F

0

8

4

1

2

3

5

6

7

C

9

A

B

D

E

F

0

8

4

1

2

3

5

6

7

C

9

A

B

D

E

F

0

8

4

1

2

3

5

6

7

C

9

A

B

D

E

F

20

26

36~5332~35 54~71 72~90 91~105 141~160

F. Dial-switch ENC1: The indoor PCB is universal designed for whole series units from 7K to 68K. This ENC1 setting will

tell the main program what size the unit is.

NOTE: Usually there is glue on it because the switch position cannot be changed at random unless you want to use this

PCB as a spare part to use in another unit. Then you have to select the right position to match the size of the unit.

“20” means 2kW (7K),“105” means 10.5kW(36K), and so on.

1

2

ON

1

2

ON

1

2

ON

1

2

ON

FACTORY

SETTING

SW5

MODE

MAINMAIN SLAVE

MAIN

NO SLAVE

FOR MAIN-SLAVE SETTING

G. Micro-switch SW5 is for setting the master or slave unit when the unit is in twin connection.

Range: Master no slave (Normal 1 drive 1 connection), Master (2 positions without difference), Slave

Loading...

Loading...