18

FA ROTEX GW - 09/2012

4 x Installation

4.6.3 Connecting the drain hoses

The system positive pressure is blown off via the safety valve

integrated in the unit. The safety valve and an automatic bleeder

are mounted in the housing of the heating circulation pump via a

plug connection. Any heating water escaping via the safety valve

is directed out via a short transparent hose (fig. 4-13, item G) out

of the ROTEX GW.

The condensate created in the boiler and the flue gas system by

the cooling of the combustion gases is directed to the condensate

siphon via the condensate pipe and is then directed to the

condensate drain connection and to the sewerage system.

The entire blow-off line and the connection to the sewerage

system must be executed in accordance with EN 12828.

Ɣ Check the condensate drain section for leakage.

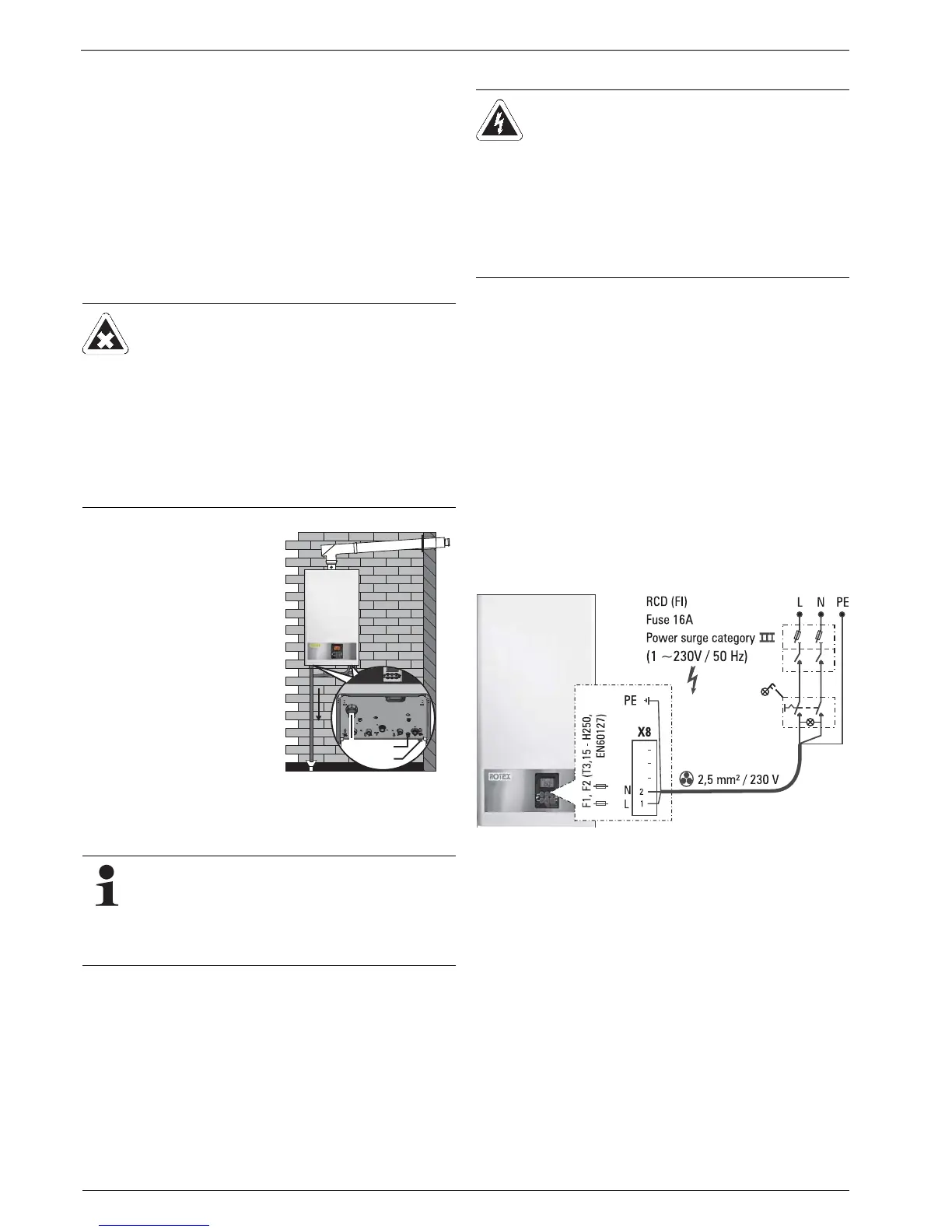

4.7 Electrical connection

All control and safety systems of the ROTEX GW are connected

and tested at the factory. Modifications on the electrical instal-

lation are dangerous and prohibited. The operator alone shall

bear responsibility for any resulting damage.

A flexible cable for the mains connection is already connected

inside the unit. Only the optional applications (e. g. outside

temperature sensor, room station, circulation pump)still need to

be connected to the controller.

Ɣ Check the supply voltage (~230 V, 50 Hz).

Ɣ Disconnect the junction box of the domestic installation.

Ɣ Connect a cable for mains connection via a main switch to be

provided by the customer and which isolates all the poles and

is still to be installed on the distribution box of the house

installation (isolating device in accordance with EN 60335-1).

Ensure that the polarity is correct.

Ɣ Restore power supply to the junction box of the domestic

electrical installation.

DANGER OF CHEMICAL BURNS!

The condensate coming from the burner contains acid

and can cause injury if it comes into contact with the

eyes or the skin.

Ɣ Wear protective clothing (safety glasses, rubber

gloves) when working on the condensate drain.

Ɣ If your skin comes in contact with anything, wash

the affected area immediately with tap water.

Ɣ If the chemicals come in contact with eyes,

immediately wash with tap water and consult an

ophthalmologist.

Ɣ Direct the condensate drain

hose (Ø 18/24 mm)

mounted on the condensate

siphon (fig. 4-13, item F) in

the factory with constant

gradient) and with free inlet

to the sewerage

connection.

The entire outlet must not

be capable of being locked

and must direct the conden-

sate safely and visibly to the

outside.

If necessary, the factory-fit-

ted corrugated hose can be

replaced by a suitable plas-

tic hose having a minimum

inside diameter of 13 mm.

Fig. 4-13 Connection of the

condensate drain

hose

The boiler can be drained if necessary via the hose

spigot leading out of the floor of the unit between the

heating return and the cold water connection (fig. 4-13,

item H).

Ɣ To do this, open the drain valve coupled to the hose

spigot (hexagon) by 1/2 a turn.

Loading...

Loading...