37

FA ROTEX GW - 09/2012

7 x Gas burner

7.3.6 Setting the gas pressure controller

The gas valves are factory-set. As a rule, no changes should be

made to the gas pressure controller. The adjusting screw

(fig. 7-1, item 12) is hidden under a cover.

If the set value for basic load deviates to much from the target

value or if the burner tends to whistle:

Ɣ Adjust the adjusting screw for the gas pressure controller

(fig. 7-1, item 12) in small steps (maximum half a turn per

adjustment step).

Ɣ After each adjusting step, wait at least 2 minutes.

Ɣ Check the changes in the combustion quality with a flue gas

analyser.

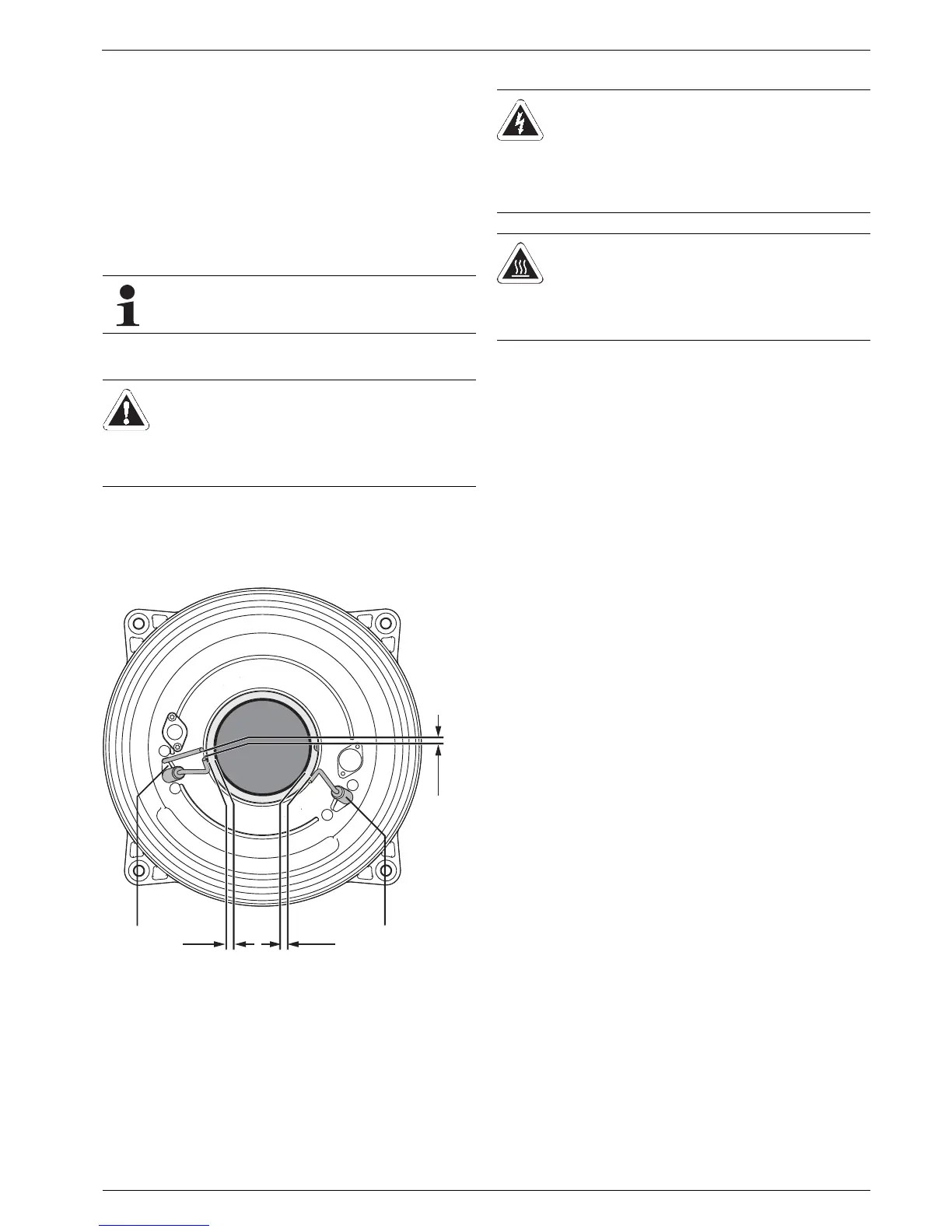

7.3.7 Setting ignition and Ionisation electrodes

The electrodes are factory-set.

For adjusting:

Ɣ Remove the burner (see chapter 7.4)

Ɣ Check and adjust the electrodes (see fig. 7-5).

7.4 Dismantling the burner

The burner works, as a rule, almost without any wear and

residue. It may be necessary to dismantle the burner for some

cleaning and servicing jobs or if there is damage in the

combustion chamber area.

If the burner produces noises in the lowest output

setting (basic load) (weather-dependent!), set the

minimum output to a higher value.

CAUTION!

Ignition electrodes can break with cold deformation.

Ɣ Dismantle the burner before adjusting the

electrodes and make the electrodes glow by using

a solder lamp.

14 Ionisation electrode 15 Ignition electrodes

Fig. 7-5 Adjustment of the ignition and ionisation electrodes

WARNING!

Live parts can cause an electric shock on contact and

cause fatal burns or injuries.

Ɣ Before removing the burner, shut off the main

switch for the heater and secure against uninten-

tional restart.

WARNING!

Danger of burning from hot surfaces (flame tube).

Ɣ Let the burner cool down sufficiently before

dismantling.

Ɣ Wear protective gloves.

Loading...

Loading...