35

FA ROTEX GW - 09/2012

7 x Gas burner

6. Start the special function "emission measurement" and set

the full load (100 %) (see chapter 6.7.1)

7. Connect the flue gas analysis unit.

8. Check flow pressure.

Î The gas inlet flow pressure must not fall significantly

below rest pressure. If the flow pressure is too low, the

burner output also drops.

9. If the measured flue gas values do not change anymore (for

the soonest 3min after the start of the burner), measure the

CO

2

-content and the O

2

-content. Compare the measured

values with the specified setting values (see chapter 7.3.1).

10. If the CO

2

concentration is outside ± 0.2 % or the O

2

concentration is outside ± 0.1 % of the set target values:

Readjust burner using the adjusting screw for the gas/air

mixture (fig. 7-1, item 11):

– Right turn (clockwise)

Î more gas: O

2

p, CO

2

n

– Left turn (counter-clockwise)

Î less gas: O

2

n, CO

2

p

11. In the special function "emission measurement", set the

minimum load (0 %) (see chapter 6.7.1).

12. If the measured flue gas values do not change anymore (for

the soonest 2min after energy change), measure the CO

2

-

content and O

2

-content. Compare the measured values with

the specified setting values (see chapter 7.3.1).

13. If the CO

2

concentration is outside ± 0.2 % or the O

2

concentration is outside ± 0.1 % of the set target values or

the burner whistles: Readjust the burner using the adjusting

screw for the gas pressure controller (fig. 7-1, item 12) (see

chapter 7.3.6):

– Right turn (clockwise)

Î more gas outlet pressure: O

2

p, CO

2

n

– Left turn (counter clockwise)

Î less gas outlet pressure: O

2

n, CO

2

p

14. In the special function "emission measurement", set the

maximum load (100 %) (see chapter 6.7.1) and check the

combustion values again.

– The values adjust according to the specifications (com-

pare step 7)

Î Adjustment procedure is finished.

– The values adjust not according to the specifications

Î repeat the steps 7-13.

15. All changes of the output setting values must be entered on

the settings type identification plate next to the type

identification plate and in the operating manual.

7.3.3 Carrying out the basic setting on the burner.

If the burner does not start, even with the power and gas supply

properly connected and with the flue gas path free, a new burner

basic setting must be carried out.

Basic setting

Ɣ Screw in the adjusting screw for the gas/air mixture (fig. 7-1,

item 11) clockwise up to the stop (do not tighten).

Ɣ Open the adjusting screw for the gas/air mixture according to

tab. 7-2 counter clockwise:

Ɣ Restart the burner.

Ɣ If the burner does not start, open the adjusting screw for

gas/air mixture further by 2 more turns and restart the

burner.

7.3.4 Changing the type of gas to natural gas LL/L or

liquid petroleum gas

The burner is factory set to the gas type indicated on the type

identification plate or on the settings type identification plate

(fig. 7-1).

1. Close the gas isolator valve.

2. Switch off the ROTEX GW and secure against restart.

3. Create access to the unit internals (see chapter 4.9.3).

4. Unscrew the bottom burner gas supply (fig. 7-3, item 1) from

the top burner gas supply and from the gas valve.

5. Remove the existing gas nozzle (fig. 7-3, item 2) from the

connection on the gas valve (do not discard).

6. Depending on the type of gas, insert the supplied liquid

petroleum gas or natural gas nozzle (fig. 7-3, item 2) in the

connection on the gas valve.

If the burner does not start, even with the power and

gas supply properly connected and with the flue gas

path free, a new burner basic setting must be carried

out (see chapter 7.3.3).

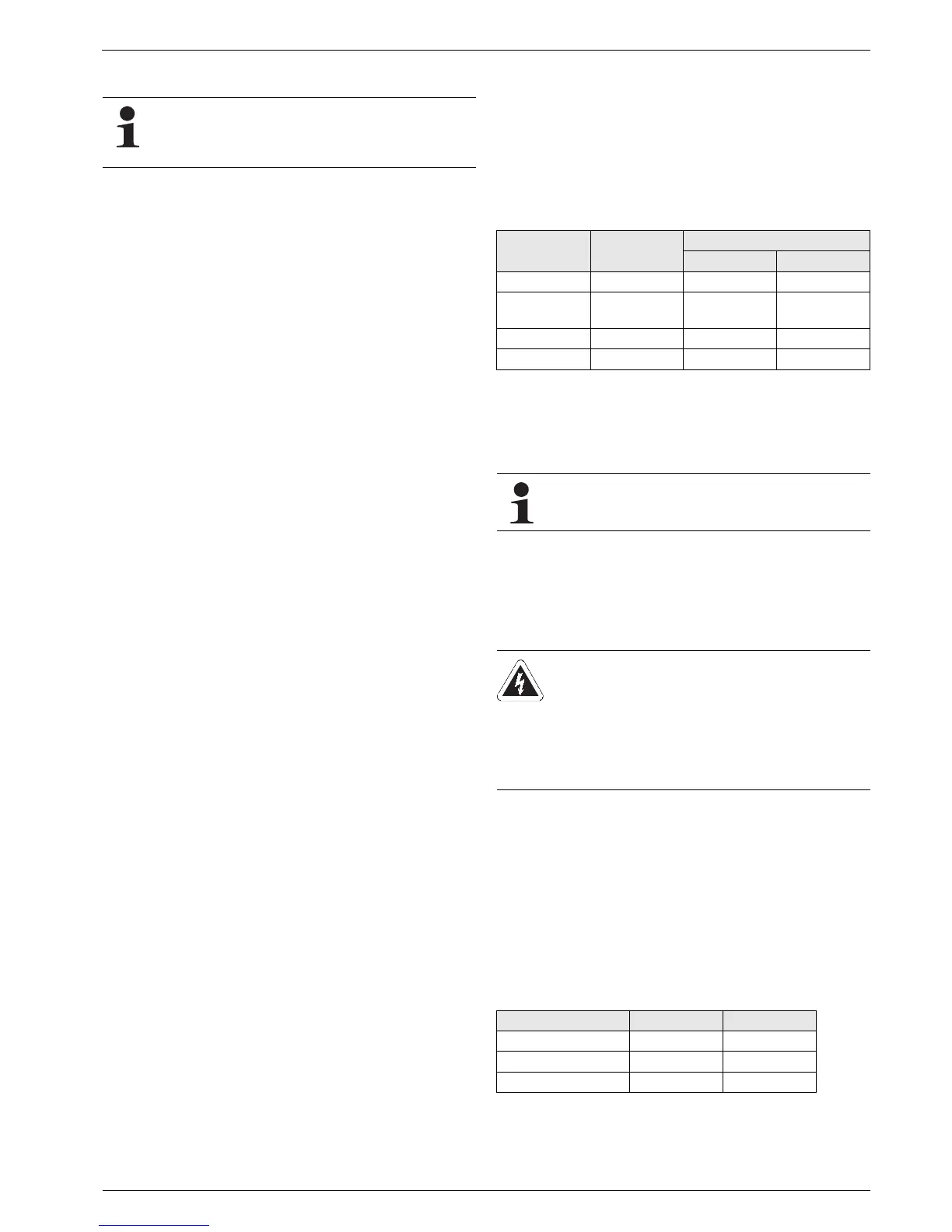

Gas type Associated

test gas

Number of rotations

GW 22C GW 26C

Natural gas E,H G20 6.5 6.5

Natural gas

LL,L

G25 8.5 8.5

Butane* G30 4 4

Propane* G31 6 6

Tab. 7-2 Number of rotations for adjusting the gas/air mixture

After carrying out the basic setting for the burner, the

burner must be checked and fine setting should be

carried out (see chapter 7.3.2).

WARNING!

Live parts can cause an electric shock on contact and

cause fatal burns or injuries.

Ɣ Before beginning maintenance work, disconnect

the ROTEX GW from the power supply (switch off

fuse and main switch) and secure against uninten-

tional restart.

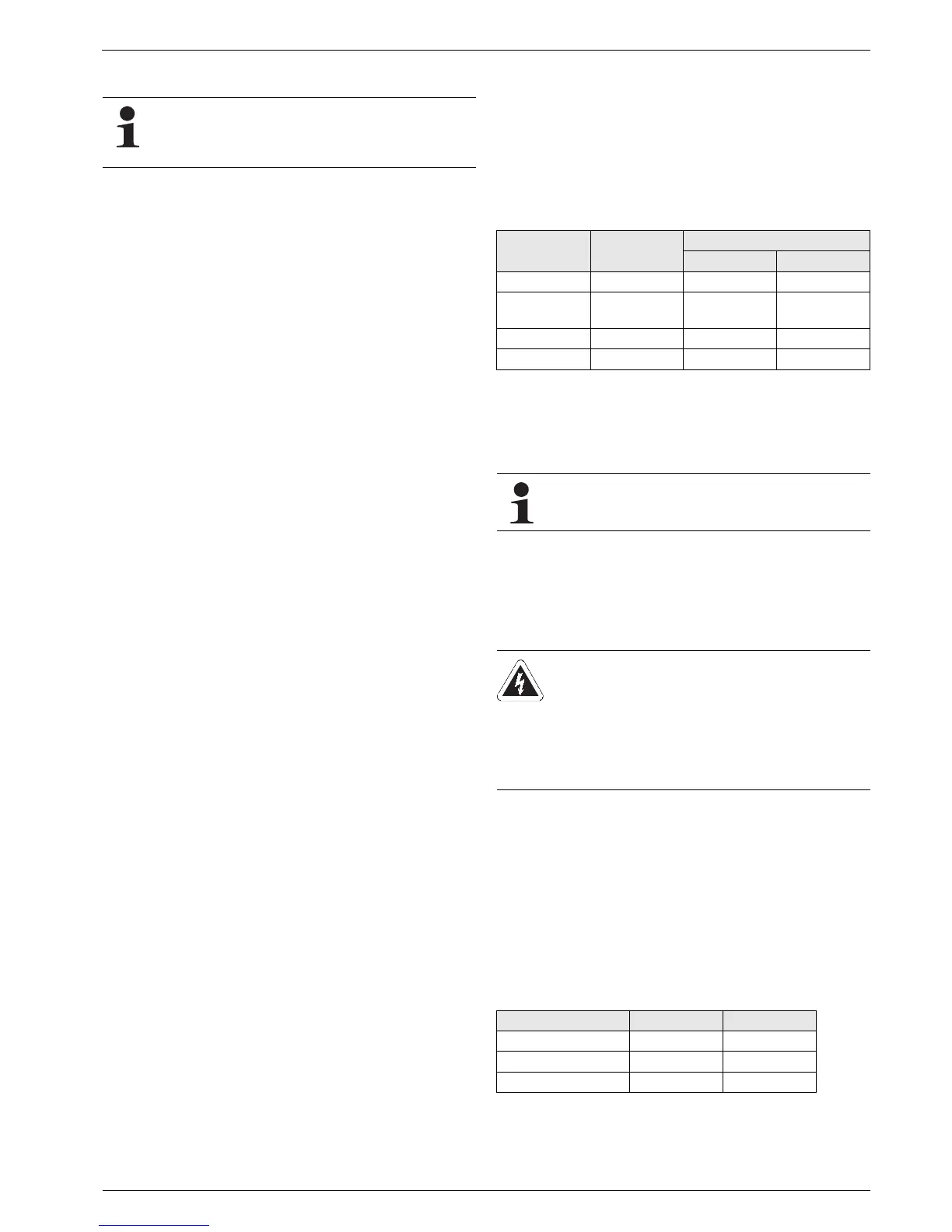

Gas type GW 22C GW 26C

Natural gas E,H Ø 5.4 mm Ø 5.0 mm

Natural gas LL,L Ø 5.6 mm Ø 5.7 mm

Liquid petroleum gas Ø 3.8 mm Ø 3.8 mm

Tab. 7-3 Gas nozzle diameter

Loading...

Loading...