41

FA ROTEX GW - 09/2012

9 x Inspection and maintenance

9.2.3 Checking and cleaning the burner

As a rule, the burner does not wear. If impurities or unsatisfactory

combustion values are ascertained, the burner must be

dismantled (see chapter 7.4), cleaned and if needed, reset (see

chapter 7.3).

Cleaning the combustion chamber

Ɣ Dismantle burner (see chapter 7.4)

Ɣ Clean the flue gas routing (brushing out and vacuuming out

the open burner chamber).

Checking the burner

Checking the burner includes visually inspecting the burner's

condition as well as making flue gas measurements.

The scope of inspection includes:

Ɣ Clean the burner surface (cloth, plastic brush).

Ɣ Conduct a visual inspection of the ignition and ionisation

electrodes for damages and correct electrode gap (see

chapter 7.3.7).

Ɣ If necessary, replace faulty parts.

Ɣ Mount burner in combustion chamber.

Ɣ Check the gas line for leakage.

Ɣ Put the burner into operation and let it run for about 5 minutes

in the chimney sweep position.

Ɣ Check combustion values:

– Flue gas temperature at measuring sockets of the flue gas

pipe. (Target value < 75 °C),

–O

2

- or CO

2

-content (see chapter 7.3.1),

– CO content (target value < 50 ppm).

Î If the combustion values lie not within the target range, the

burner must be adjusted according to chapter 7.3.

DANGER OF EXPLOSION!

Escaping gas is a direct threat to human health and

safety. Even a few sparks can cause major explo-

sions.

Ɣ Only heating specialists authorised and trained by

the gas or power supply company should be

allowed to work on gas-conducting parts.

For exact information regarding the checking and set-

ting of the burner, see chapter 7.3.

For exact information regarding the assembly and dis-

assembly of the burner, see chapter 7.4.

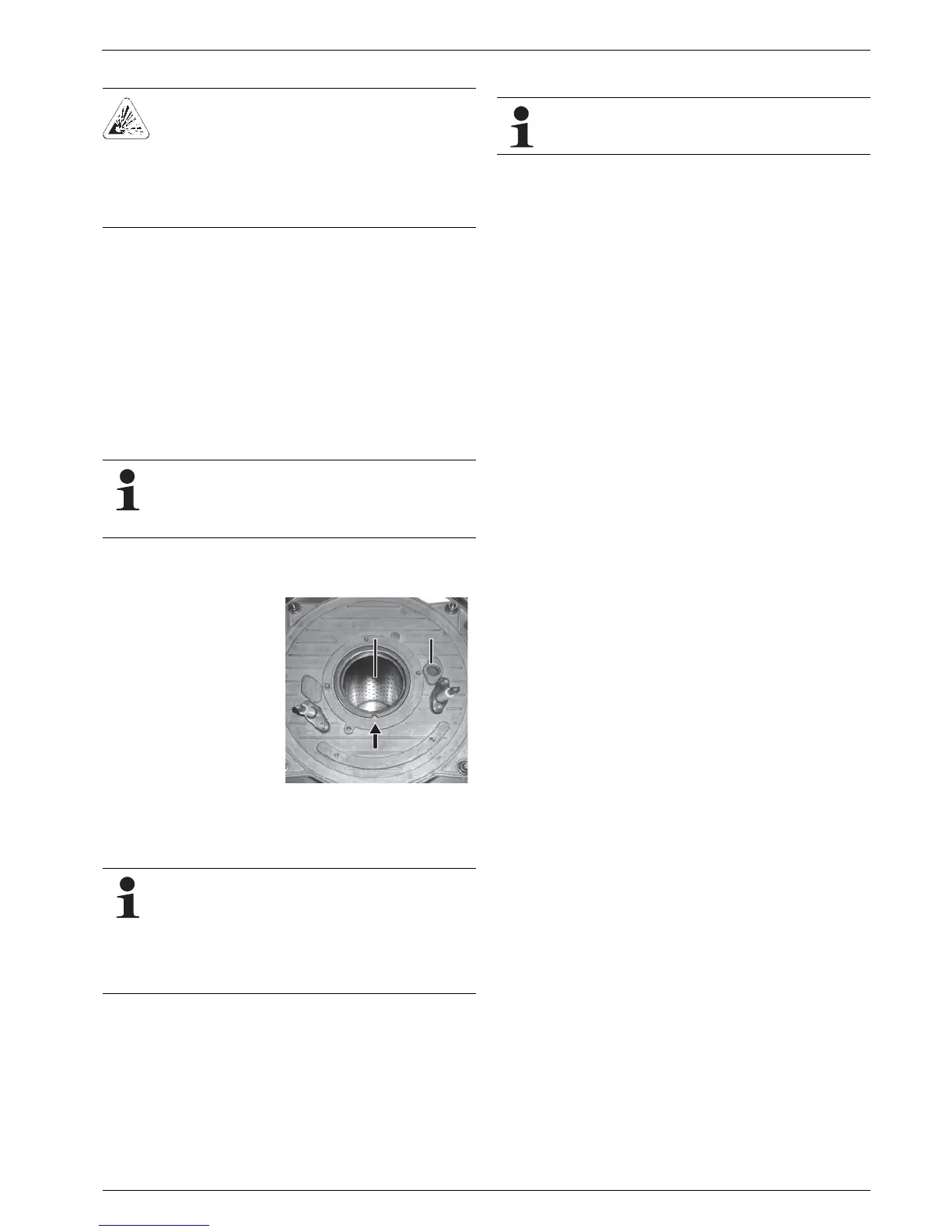

Ɣ The sight glass (item 3)

over the ignition

electrodes must be clean

and be in perfect

condition.

Fig. 9-2 Checking the sight glass

In the course of maintenance work, the safety relevant

components must be additionally inspected for the

expiration of their nominal service life:

– Ignition transformer: 10 years or 250,000 burner

starts,

– Gas valve: 10 years or 250,000 burner starts,

– Overpressure safety valve: 10 years.

1

Loading...

Loading...