23

FA ROTEX GW - 09/2012

5 x Start-up

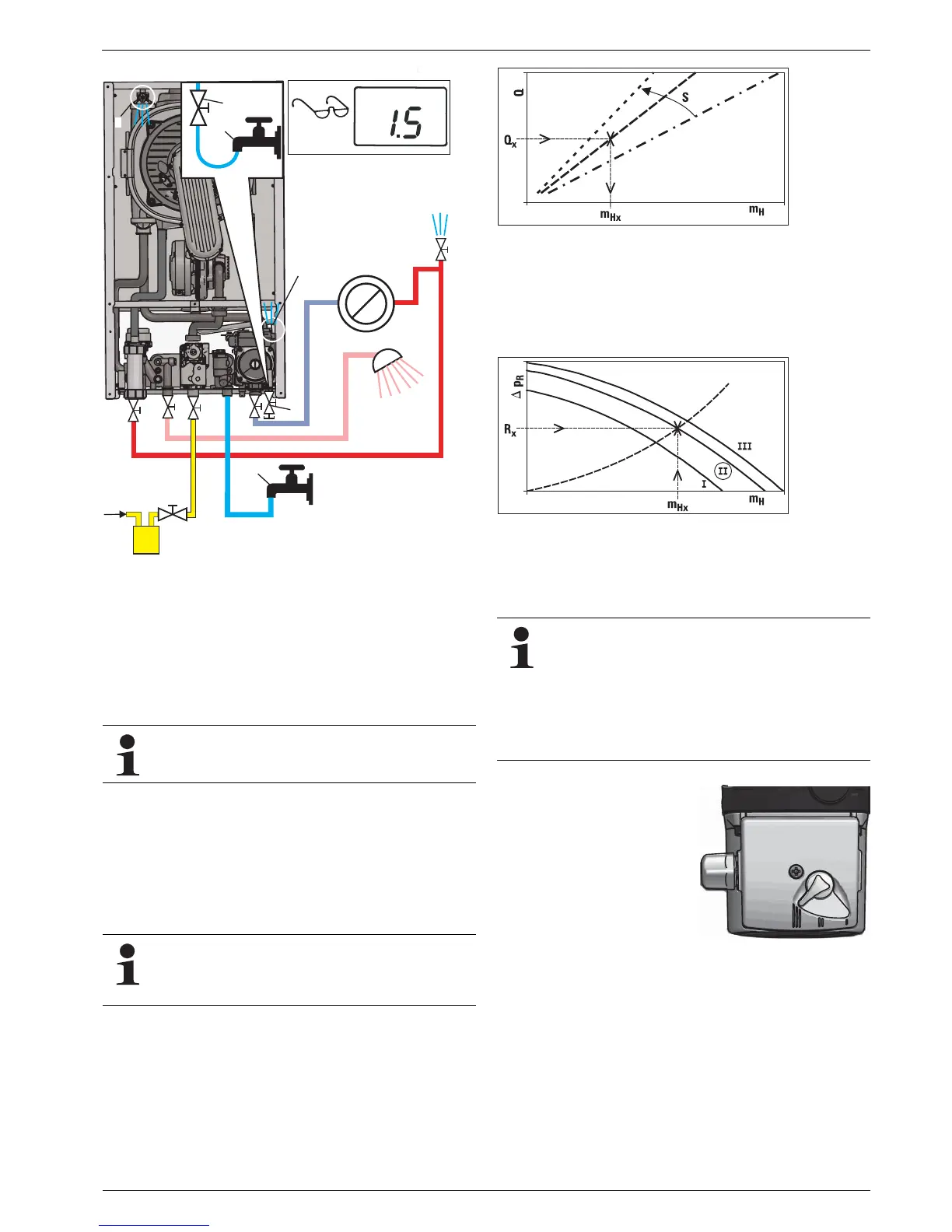

Setting pump speed of heating circulation pump

The prerequisite for the most energy-saving method of operation

is that a hydraulic balance is carried out and the heating circu-

lation pump is running at the lowest possible necessary stage.

The instructions for hydraulic incorporation (see chapter 8) and

the characteristic curves of the residual feed height (chapter 12,

fig. 12-3 and fig. 12-4) must be observed.

Ɣ Fully open all the radiator thermostats / regulating valves.

Ɣ On the ROTEX GW set the highest nominal room temper-

ature so that the burner and the heating circulation pump

operate.

Ɣ In the heating performance diagram (chapter 12 "Technical

data", fig. 12-5) determine the associated flow rate (m

Hx

) for

a specific heating output (Q

x

) depending on the layout

spread.

Ɣ Determine the hydraulic resistance in the heating circuit (R

x

).

Ɣ Based on fig. 12-3 and fig. 12-4 (chapter 12 "Technical data")

determine the output stage of the heating circulation pump.

Fig. 5-2 Filling and bleeding

The pump speed is set in the factory to the highest

pump stage.

The design spread describes the temperature differ-

ence between the flow and return flow of the heating

system under design conditions (generally -12 °C out-

side air temperature).

m

H

Flow heating network Q Heating output

S Spread

Fig. 5-3 Determination of the layout flow rate

m

H

Flow heating network

R

x

Hydraulic resistance in the

heating circuit

'

p

R

Remaining pumping height

I, II, III Pump stages integrated

heating circulation pump

Fig. 5-4 Determination of the required pump output stage

In practice, the hydraulic resistance in the heating net-

work is often not known. By observing the flow and

return flow temperatures on the heat generator, you

can determine whether the pump would still provide

adequate output at a lower speed level.

The difference between the flow and return flow tem-

perature must not be greater than the design spread

and each room must still get warm enough.

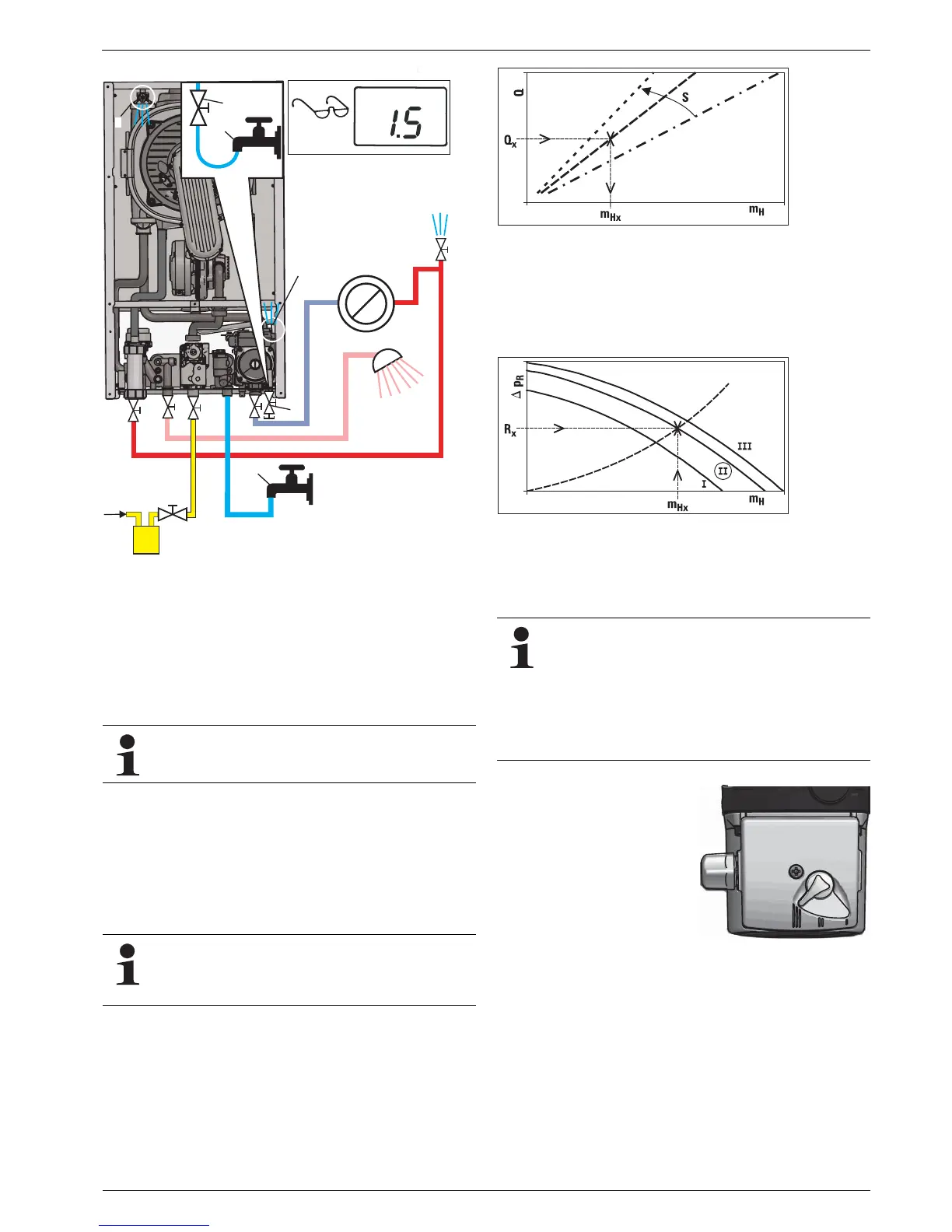

Ɣ Setting the heating circu-

lation pump to the required

output stage.

Fig. 5-5 Setting pump speed

Loading...

Loading...