Operating Instructions 6-5 SG8 Manual

Cutting Counter Bores for Seat Rings:

Align the work piece as explained previously. Cylinder head deck surface must

be up.

Insert correct pilot into the valve guide. Mount the correct milling head cutter

on the milling head Adapter, Install milling head adapter into spindle adapter

Float the machine workhead while feeding the spindle down into the pilot until

milling head is few thousand from contacting the seat, release the foot pedal to

lock the floating head, rest the cutter gently on the surfaces and set the positive

stop with the seat ring between the stop rod and the quill clamp. This will ensure that

quill travel will be limited to the correct amount; or use the following alternative

method:

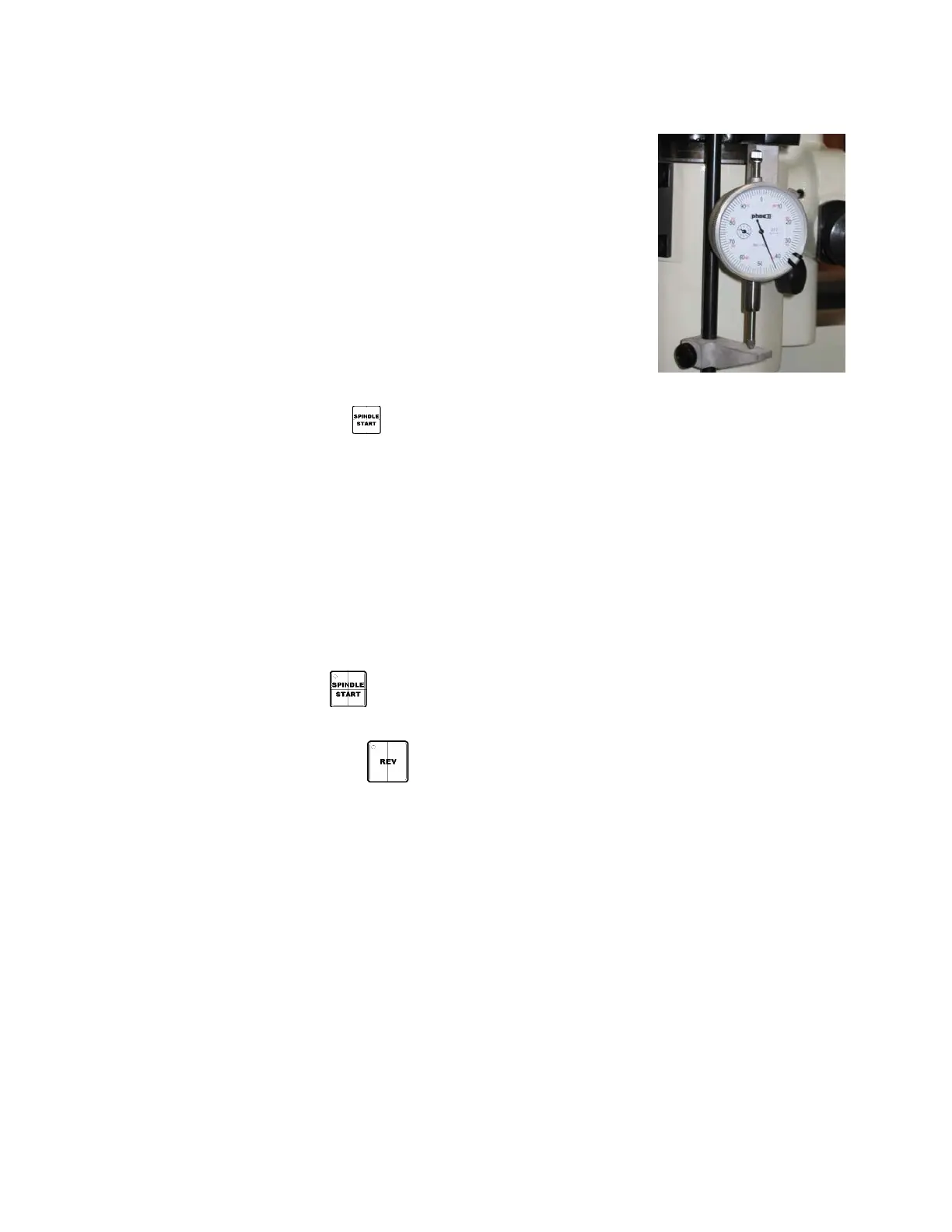

Set dial indicator for feed depth to zero, being certain the indicator has

sufficient travel to allow the proper depth of cut.

Push the green Spindle Start button to start the spindle rotation. Turn the spindle at

approximately 80 RPM - larger seats may require a slower speed; smaller seats may be run faster. Observe dial

indicator or positive stop. Cut to proper depth.

Swing the indicator out of the way after completing the procedure.

.

Tapping Operations:

Place the Jacobs chuck or Collet Holder in the spindle as explained previously. Install tap in the chuck, and

tighten.

Center over the hole to be tapped

Push green button Spindle Start to start rotation of the spindle and feed down the hole.

Choose a spindle speed sufficient for the tap (approximately 50 RPM), and allow the tap to feed the spindle

as it threads the hole.

When the proper depth is achieved, press to reverse the spindle rotation and left spindle return the

tap off the hole.

Loading...

Loading...