Operating Instructions 3-2 SG8 Manual

Leveling the Machine:

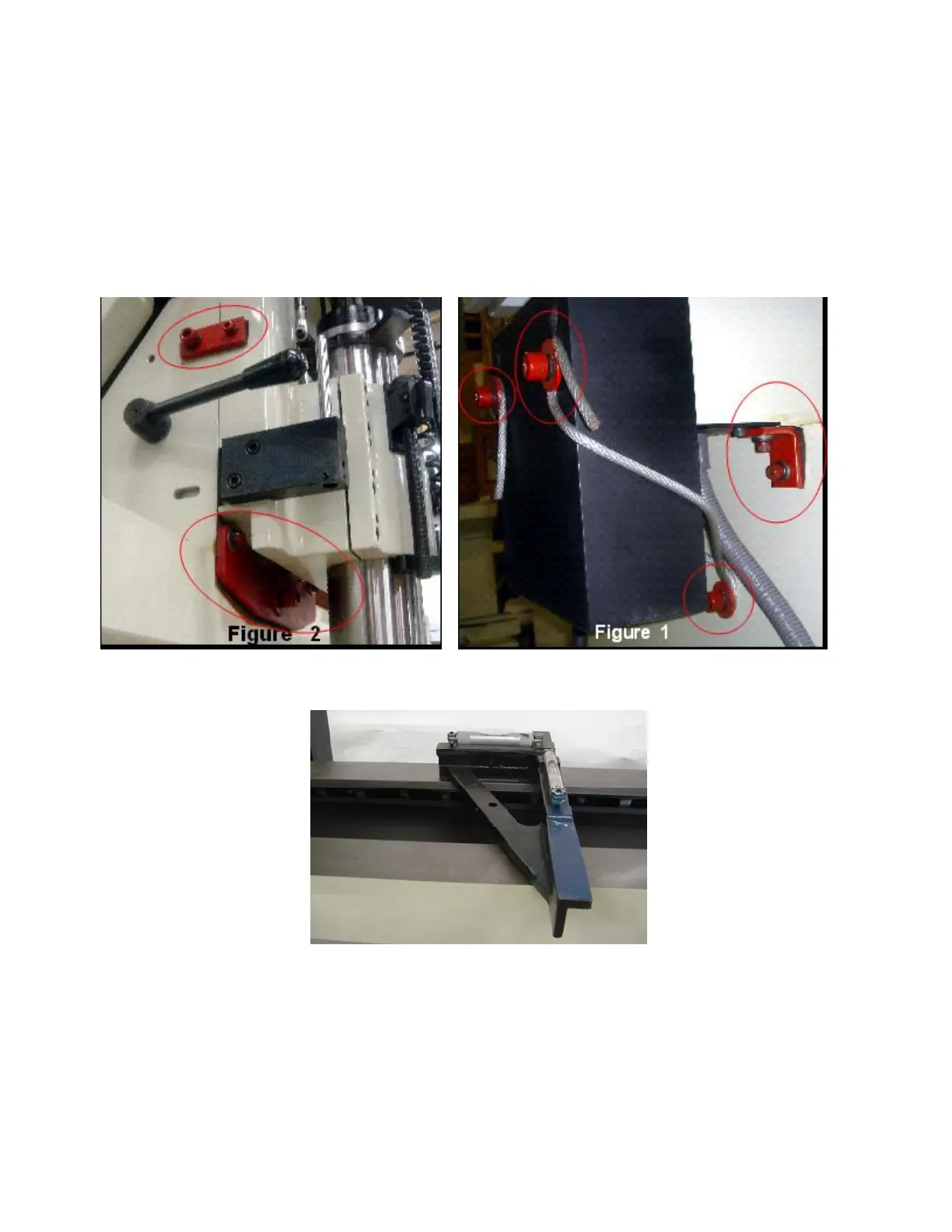

Before leveling the machine, loosen and remove the shipping brackets securing the air float Workhead.

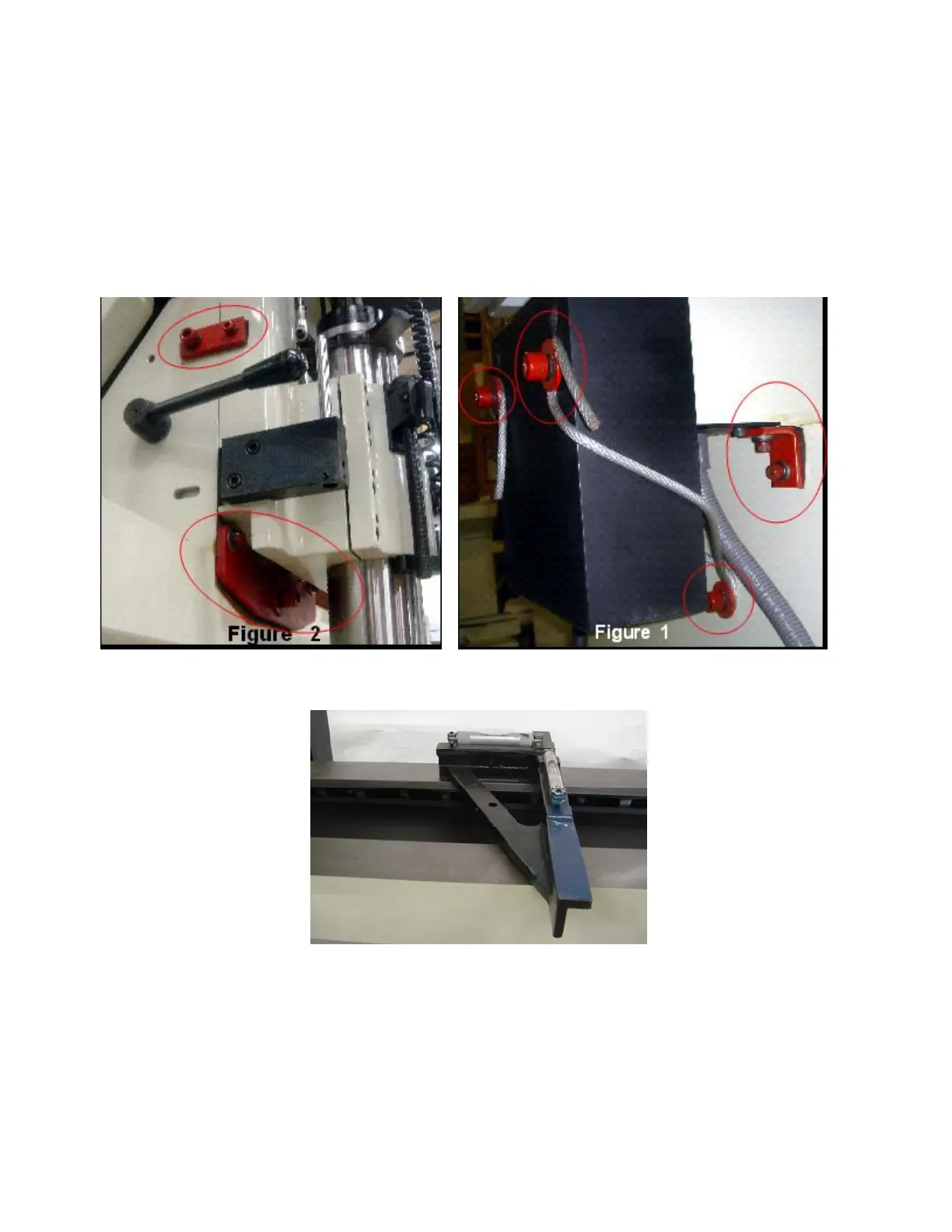

(Figures 1 & 2). The air float clamp plate bolts may need to be loosened also. Access to these bolts is gained by tilting the

spindle assembly to the left and loosening the bolts on that side approximately 1 turn. Access to the right side

bolts is obtained by tilting the spindle to the right. Caution: Do not loosen more than necessary to allow the head to

float. Clamp assembly will not clamp tight if bolts are loosened too much. It is best to hold nylock locking nut secure on

top side and loosen bolt with wrench from underside of clamp plate.

Required machinist level. (Starret 98 or better).

Use the level on the upper float surface, level the machine as precisely as possible, front to back and side to

side. Level is obtained fastest when using a three point leveling method. To utilize a three point leveling method, use only

the front outside leveling bolts and the middle bolt in the rear. Use a socket wrench to turn the leveling bolts. After

the machine is leveled bring in the other leveling bolts. Be certain all leveling bolts are effectively supporting the

machine. Tighten jam nuts on leveling bolts and recheck level.

Loading...

Loading...