VERTICAL CONTACT TOASTER

14 P/N 1010807 Rev. I 06/12

MAINTENANCE (continued)

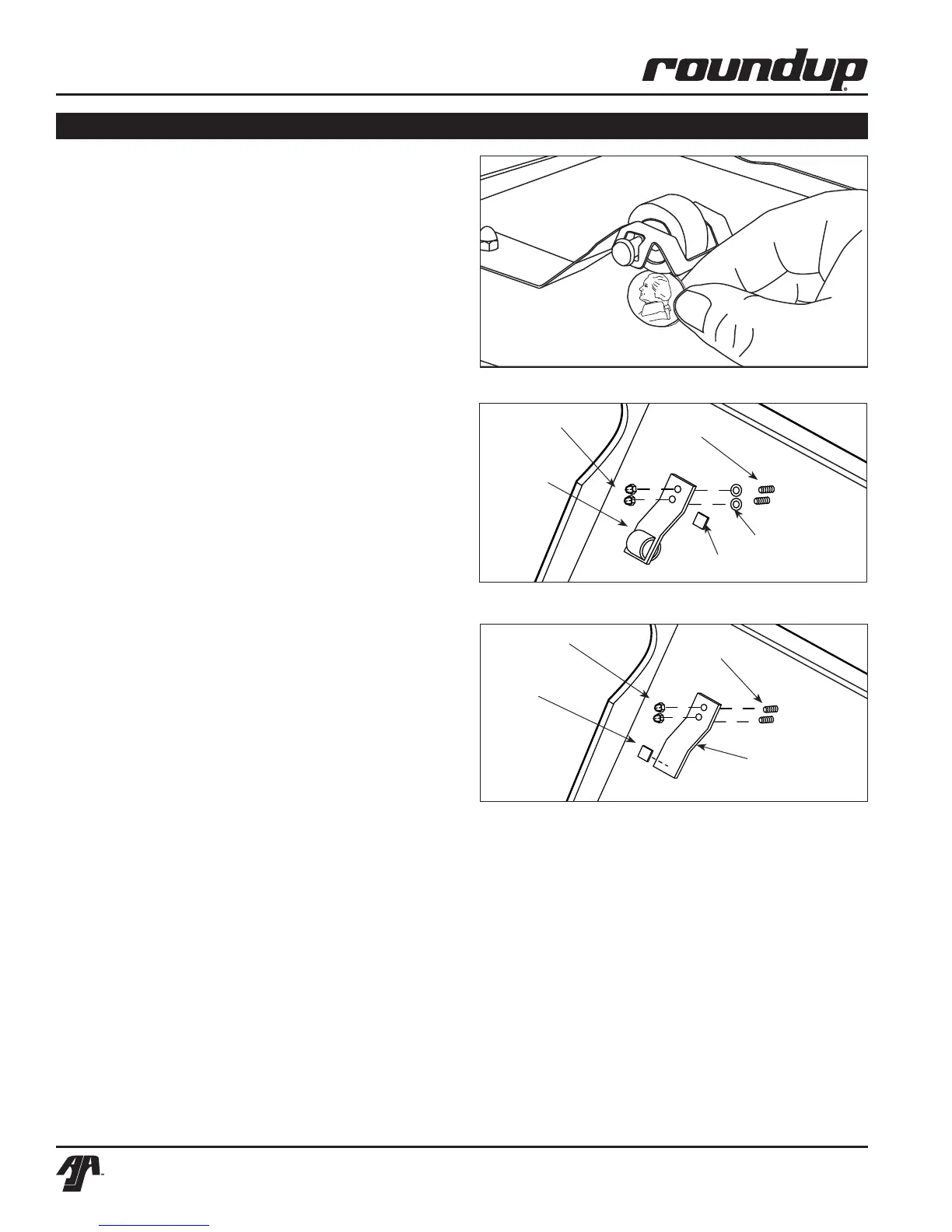

Weld

Screws

Acorn Nuts

Spacers

Tensioner

Assy.

Tape

Figure 15. Replacing Roller Tensioner Assy.

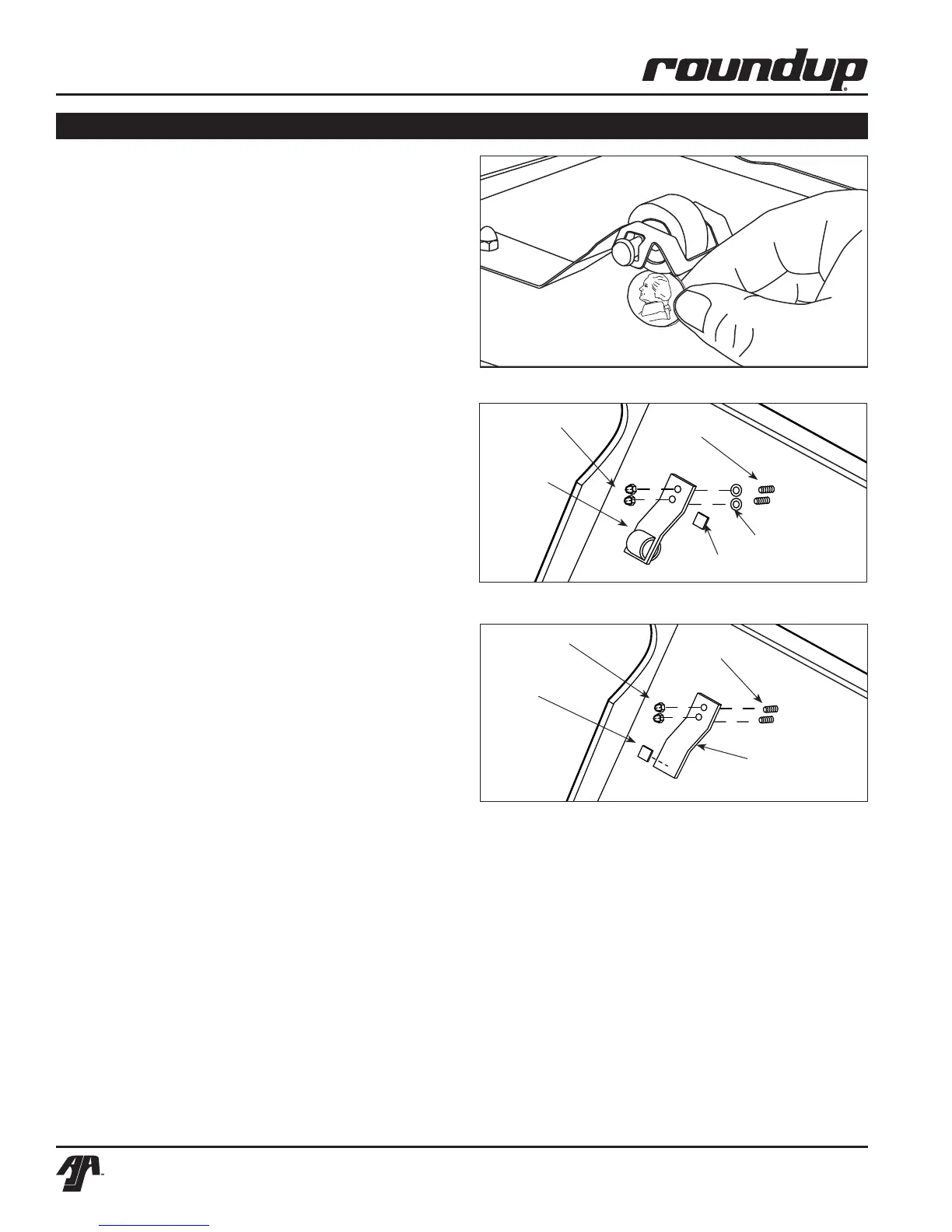

Figure 14. Measuring Roller Tensioner

Figure 16. Replacing Spring Tensioner Assy.

Weld

Screws

Acorn Nuts

Spring

Tensioner

Assy.

Tape

Checking the Roller Tensioners

(every 3–6 months)

MEASURING THE ROLLER TENSIONERS

1. Measure the Roller Tensioner on both inner

Conveyor Covers (Figure 14) using a U.S Nickel.

2. The space between the inner Conveyor Cover

and bottom of the Tensioner wheel should be

13/16” (2.1 cm) or the height of a U.S. Nickel.

3. Adjust or replace any damaged ones as

recommended.

REPLACING THE ROLLER TENSIONERS

1. Remove the acorn nuts and old Roller Tensioner

Assembly (Figure 15).

2. Replace Tensioner Assembly, and reassemble.

3. Make sure the spacers are placed inside the

Tensioner arm. The spacers are smaller than the

holes to allow the Tensioner to pivot freely.

REPLACING THE SPRING TENSIONER

1. Remove the acorn nuts (Figure 16).

2. Remove the old Spring Tensioner Assembly

(Figure 16).

3. Replace Tensioner Assembly and reassemble

unit.

Loading...

Loading...