MODEL: N74A1-63510/N74A3-63610/N74B1-63510B/N74B3-63610B

10

Note:

●If the water outlet or water tank is installed higher than control valve

or parallel interlock system with multi-outlets, a liquid level controller

must be installed in brine tank. Or else, the water in water outlet or

water tank will flow backwards into brine tank when backwash.

●If making a soldered copper installation do all sweat soldering

before connecting pipes to the valve. Torch heat will damage plastic

parts.

●When turning threaded pipe fittings onto plastic fitting, use care not

to cross thread or broken valve.

●If the valve belongs to time clock

type ( N74A1 or N74B1), there are no

step ②.

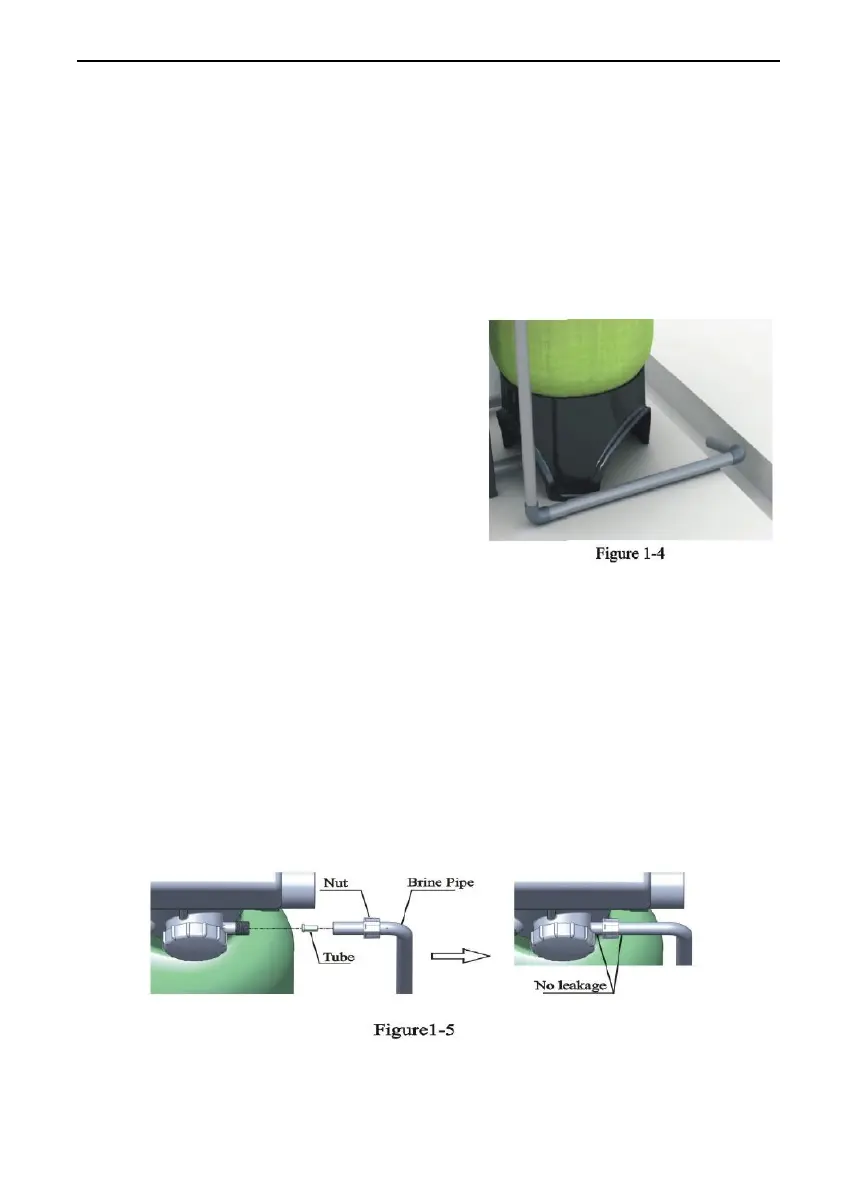

④ Install drain pipeline

Insert drain line flow control into drain

outlet, use UPVC glue to connect drain

outlet with UPVC drain pipeline as

Figure 1-4 shows.

Note:

●Control valve should be higher than

drain outlet, and be better not far from the drain hose.

●Be sure not connect drain with sewer, and leave a certain space

between them, avoid wastewater be absorbing to the water treatment

equipment, such as showed in the Figure1-4.

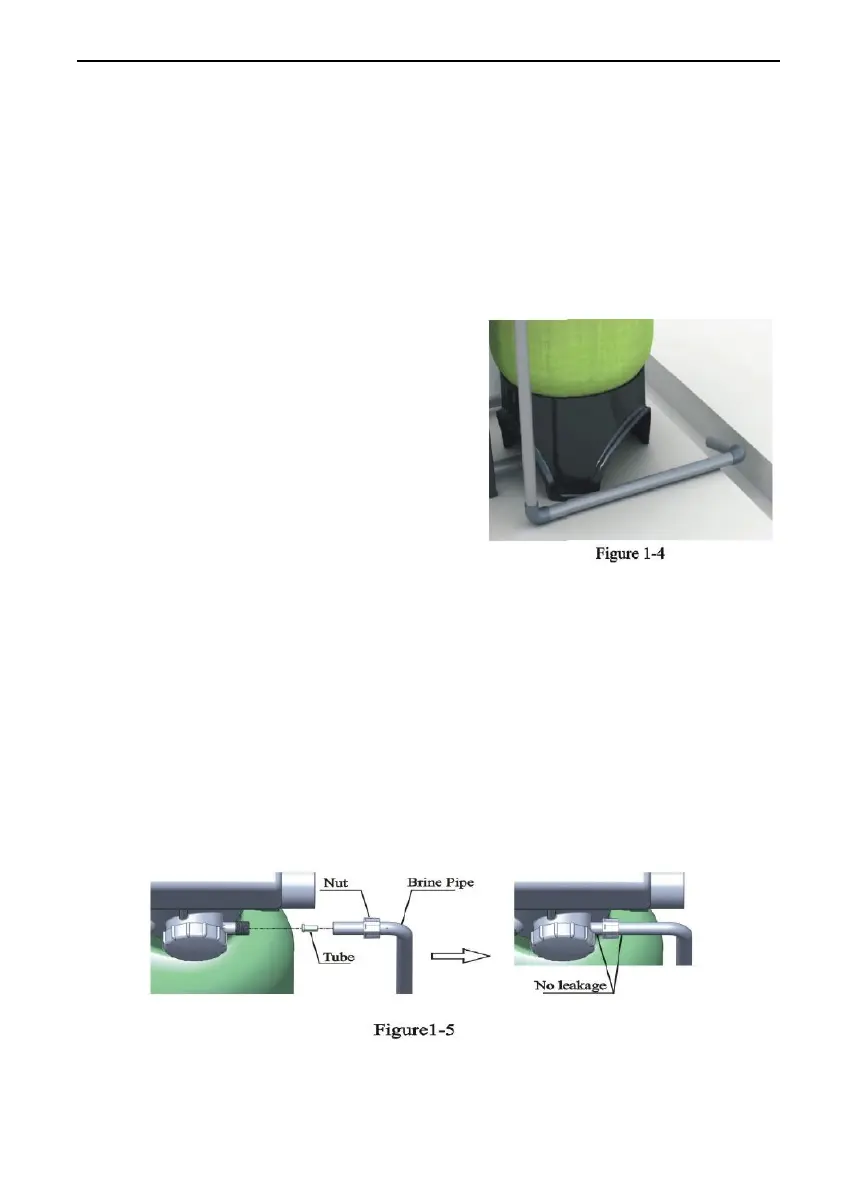

⑤ Connect brine tube

a. As Figure1-5 shows, slide 1/2″ brine tube hose connector over end of

brine tube.

b. Insert tube bushing into the end of brine tube.

c. Tighten brine draw hose connector onto brine line connector.

d. Connect the other end of brine tube with the brine tank. (The liquid

level controller and air-blocker should be installed in the brine tank.)

Remark: The brine tube and drain pipeline should not be bended or

plugged.

Loading...

Loading...