37

SALICRU

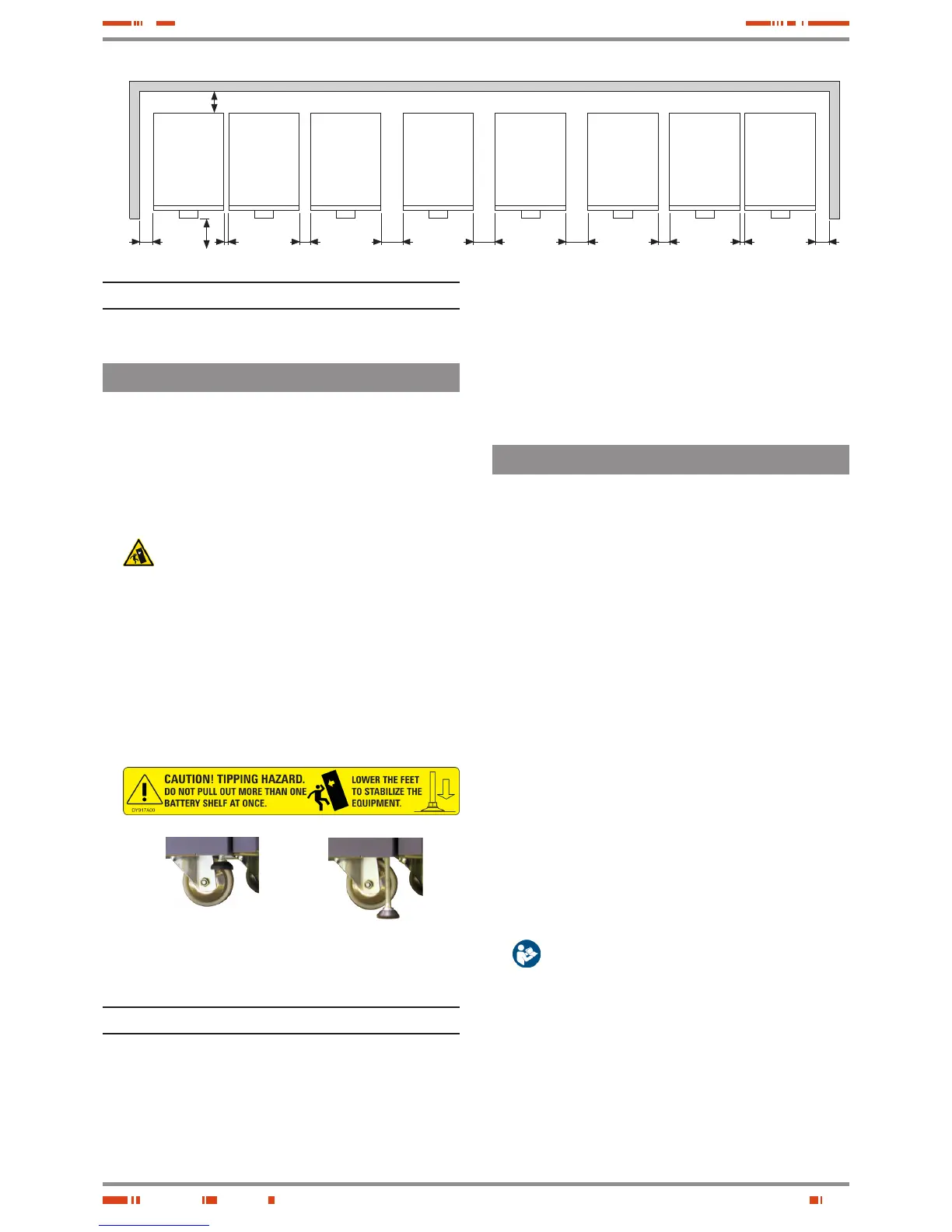

150 cm.

50 cm.

10 cm.25 cm. 25 cm. 50 cm.50 cm. 50 cm. 25 cm. 10 cm. 25 cm.

UPS battery

cabinet nr 1

UPS battery

cabinet nr 2

UPS cabinet

nr 1

UPS cabinet

nr 2

UPS cabinet

nr 3

UPS cabinet

nr 4

UPS battery

cabinet nr 3

UPS battery

cabinet nr 4

Fig. 31. Floor view with minimum distances for a parallel system.

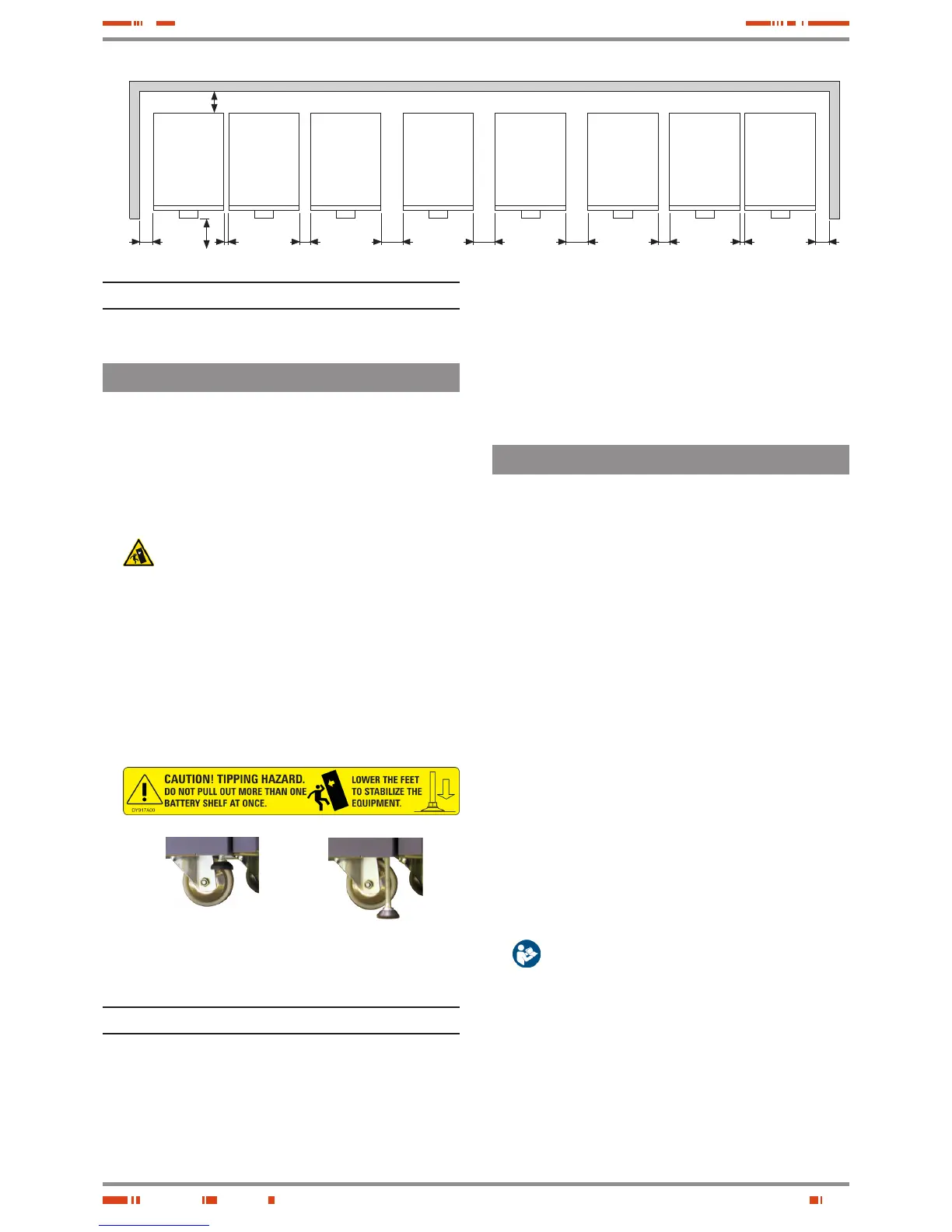

5.1.4.3. Equipment immobilized and levelled.

• All UPSs from SLC CUBE3+ series and battery modules,

which have casters, have 4 stabiliser elements (PB), arranged

next to each caster.

• The purpose of the stabilisers elements (PB) is lay, immobilize

and level the metallic cabinet once it has been located, in order

to avoid possible overturns, in particular those ones that battery

shelves can be extracted.

Warning! Turnover danger when extracting the battery

shelves without stabilising the unit previously. Do not ex-

tract more than one shelf at the same time, high risk of

causing serious injuries to the operators due to the im-

pact of the possible fall and/or trapping of the equipment.

• Loosen the elements (PB) by hand turning them counter-clock-

wise as far it would go with the floor and with the help of a

spanner, loosen them half turn more in order to immobilize the

metallic cabinet, having a correct levelling.

Fig. 32 shows how the stabilizers elements (PB) have to be

finally.

Element (PB) tighten

against the floor.

Original position from factory

of the element (PB).

Fig. 32. Equipment / battery module stabilisers elements (PB).

• Equipment maintenance and battery handling is a reserved task

to the S.T.S. or authorised staff.

If for any reason, the battery sliding shelves would need and

intervention, it is essential to pay attention and respect the in-

dications of the label sticked in each shelf, before extracting

them (see Fig. 32).

• To have access to the battery shelves, cabinet side covers have

to be removed and they have to unblocked. Shelves can be ex-

tracted through both sides and each one has a stopper.

5.1.4.4. Preliminary considerations before connecting.

• The description of this manual refers to the connection of terminals

and switching manoeuvring that are only available in some versions

or equipments with extended back up time. Ignore those opera-

tions regarding them, if the unit does not have them.

• Follow and respect the instructions described in this section re-

ferred to the installation of a single equipment or parallel system.

• Switchgear or external manual bypass panel boards:

It is advisable to have an external manual bypass panel

board equipped with input, output, static bypass (CUBE3+

B version only) and manual bypass protections, in single in-

stallations.

For parallel systems up to two units it is very is very ad-

visable having a switchgear panel board and for systems

with 3 or 4 equipments, it is essential. Switches of the

panel board have to allow isolating the UPS from the system

against any wrong operating and feed the loads with the

rest ones, either during the preventive maintenance period

or the reparation of itself.

• Under request an external manual bypass panel board for a

single equipment or parallel system can be supplied.

Also it can be manufactured by yourself, paying attention to the

version and setting of the available equipment or system and the

attached documentation in the CD relating to «Recommended in-

stallation».

• The «Recommended installation» information for each input

and output setting is available with the supplied documenta-

tion, manual and/or CD. In that information is shown the circuit dia-

gram, as well as the protection size and minimum cross section of the

wires that are connected to the equipment, taking into account the

nominal operating voltage. All figures are calculated for a maximum

total cable length of 30 m between the distribution panel board,

equipment and loads.

For longer lengths correct the cross sections accordingly, in

order to avoid dropping voltages, by respecting the Regulations

or norms corresponding to the country.

In the own documentation and for each setting, it is available

Loading...

Loading...