EB 3018 EN 8-1

Malfunctions

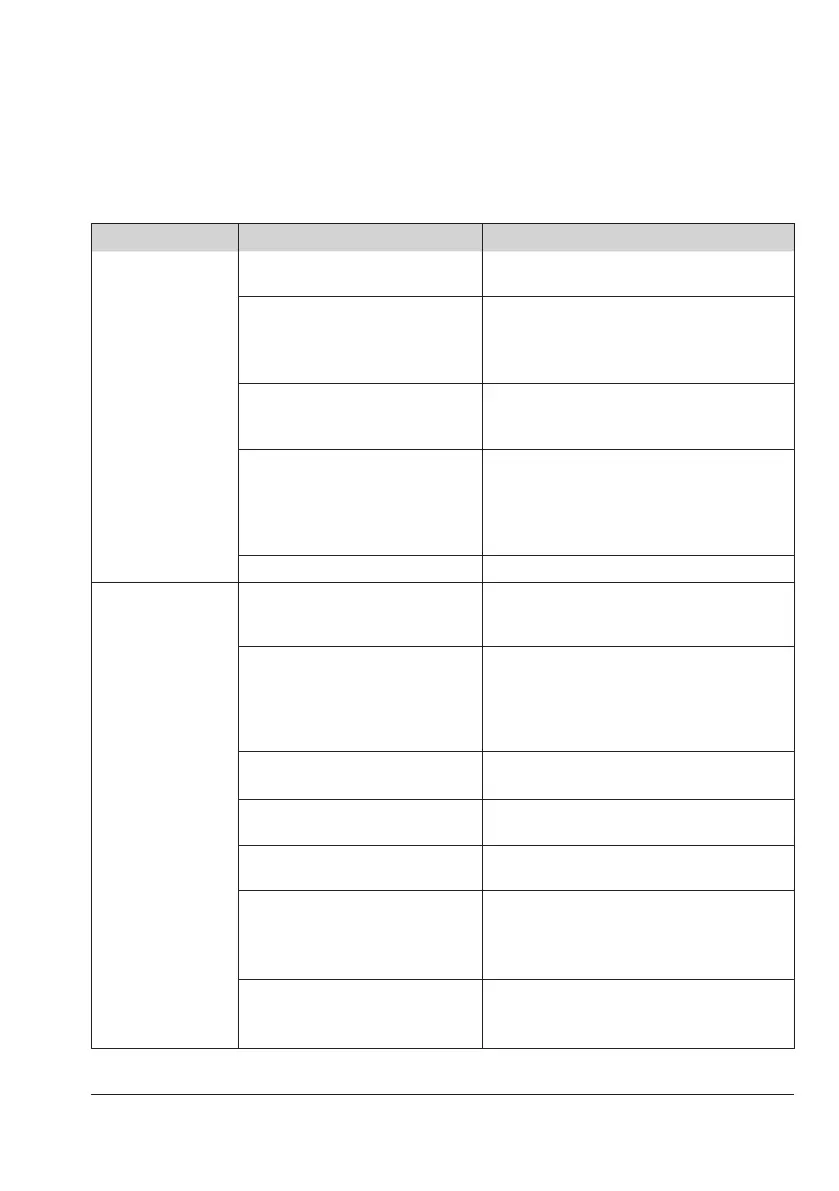

8 Malfunctions

8.1 Troubleshooting

Malfunction Possible reasons Recommended action

Flow rate exceeds

adjusted set point.

Insufcient pressure pulses on the

operating diaphragm

Î Clean the control line and screw ttings.

Foreign particles blocking the plug

Î Remove foreign particles.

Î Replace damaged parts.

Î Contact SAMSON's After-sales Service.

Seat and plug are worn or leak.

Î Replace the damaged seat and plug.

Î Contact SAMSON's After-sales Service.

Valve too large for control task (ow

rate) or too small (differential pressure)

Î Check the sizing.

Î Change K

VS

/C

V

coefcient, if necessary or

install a different sized regulator.

Î Contact SAMSON's After-sales Service.

Defective operating diaphragm Î Replace damaged diaphragm.

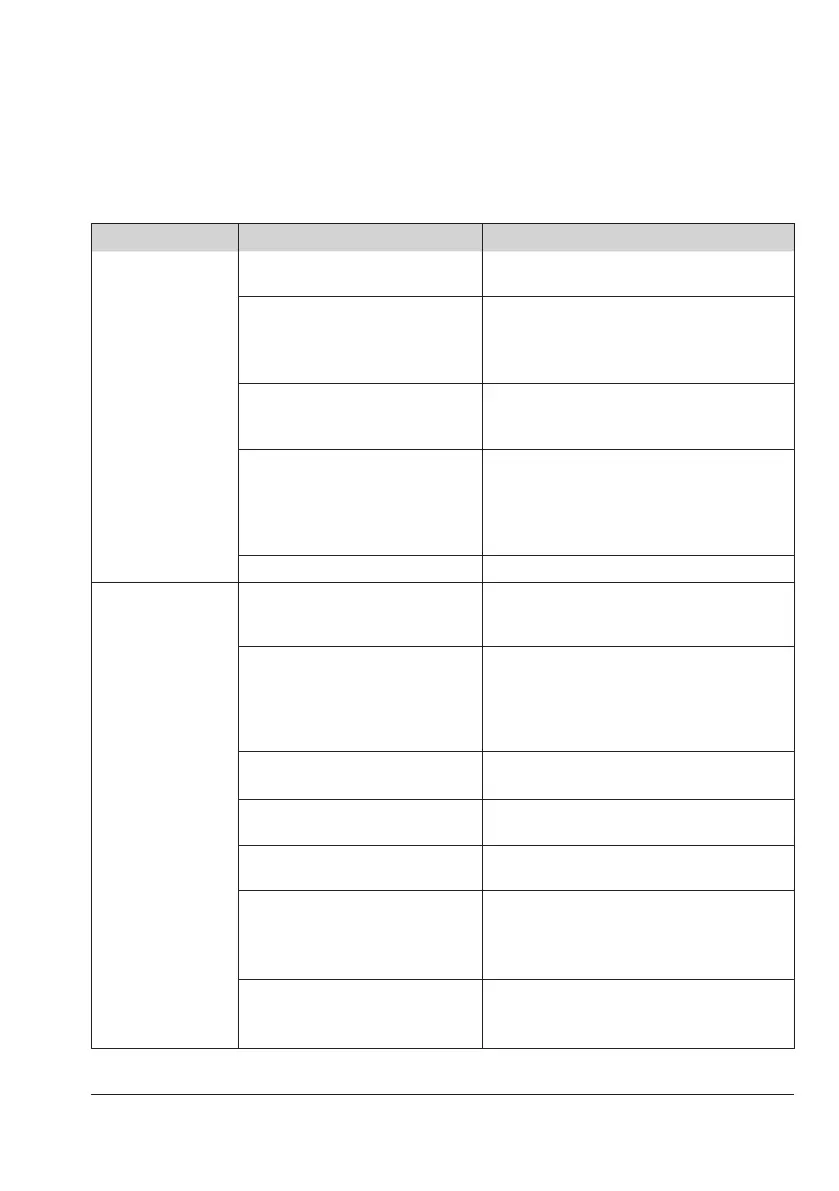

Flow set point not

reached.

Regulator installed against the ow

Î Install the regulator so that the direction of ow

matches the direction indicated by the arrow on

the body.

Regulator or K

VS

/C

V

coefcient too

small

Î Check the sizing.

Î Change K

VS

/C

V

coefcient, if necessary or

install a different sized regulator.

Î Contact SAMSON's After-sales Service.

Incorrect set point range selected

Î Check set point range

Î Contact SAMSON's After-sales Service.

Safety device, e.g. pressure limiter, has

been triggered

Î Check plant. If necessary, unlock safety device.

The fail-safe action of the actuator has

been triggered.

Î Check the plant and place the actuator back

into operation.

Plant differential pressure Δp too low

Î Compare differential pressure in the plant with

the plant’s drag.

Differential pressure across the plant:

∆p

min

=∆p

restriction

+(V/K

VS

)²

Foreign particles blocking the plug

Î Remove foreign particles.

Î Replace damaged parts.

Î Contact SAMSON's After-sales Service.

.

Loading...

Loading...