EB 8026 EN 41

Malfunctions

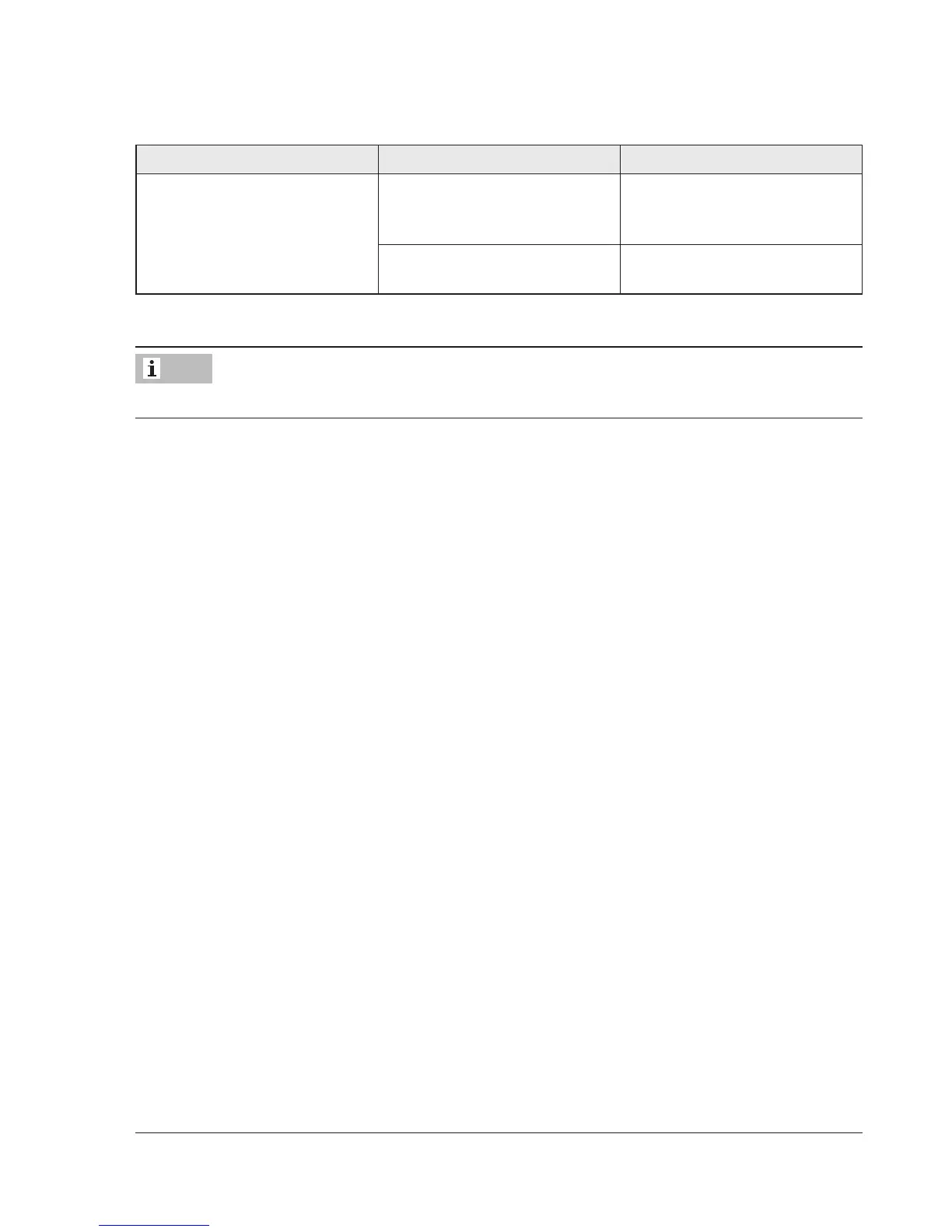

Malfunction Possible reasons Recommended action

Increased ow through closed

valve (seat leakage)

Dirt or other foreign particles de-

posited between the seat and

plug.

Shut off the section of the pipe-

line and ush the valve.

Valve trim is worn. Contact SAMSON's After-sales

Service department.

1)

A label on the ange (2) indicates whether an adjustable packing is installed.

Contact SAMSON's After‑sales Service department for malfunctions not listed in the table.

Note

8.2 Emergency action

Upon supply air or control signal failure, the

valve moves to its fail-safe position (see sec-

tion3.1).

The plant operator is responsible for emer-

gency action to be taken in the plant.

In the event of a valve malfunction:

1. Close the shut-off valves upstream and

downstream of the control valve to stop

the process medium from owing

through the valve.

2. Check the valve for damage. If neces-

sary, contact SAMSON's After-sales Ser-

vice department.

Putting the valve back into operation after

a malfunction

Î Slowly open the shut-off valves. Allow

the process medium to slowly ow into

the valve.

Loading...

Loading...