EB 6116 EN 39

Malfunctions

8 Malfunctions

Depending on the operating conditions, check the valve at certain intervals to prevent a pos-

sible failure before it can occur. Operators are responsible for drawing up an inspection and

test plan.

SAMSON's After-sales Service can support you in drawing up an inspection and test plan

for your plant.

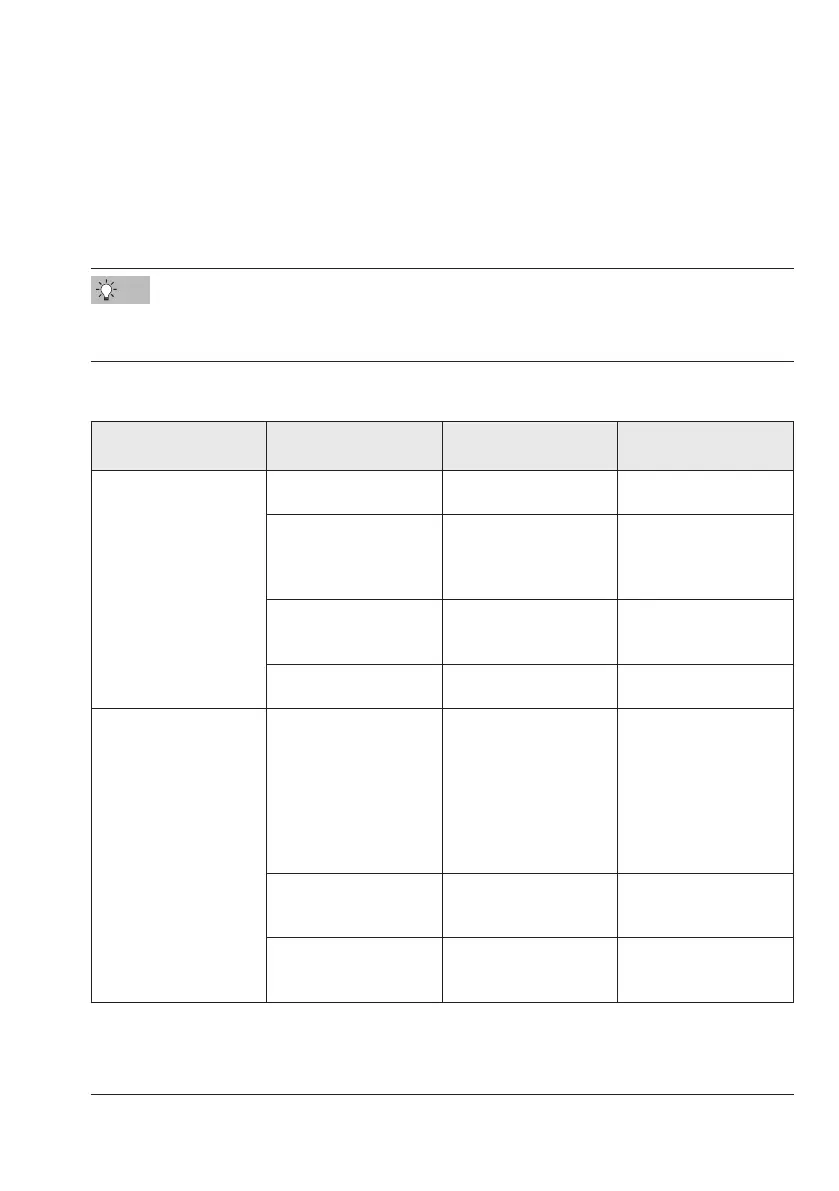

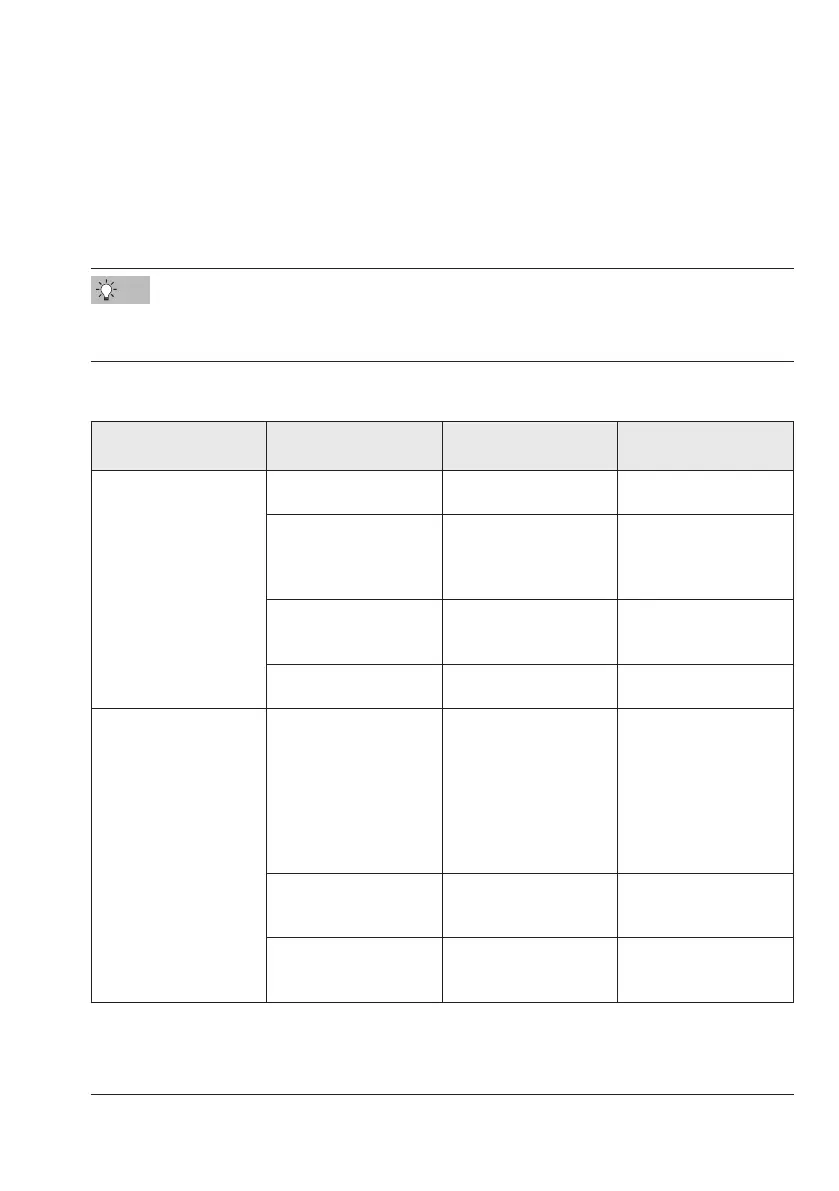

Table5: Troubleshooting

Malfunction

Possible reasons Corrective action to be

taken

Comments

No output signal

despite changing the

input signal

Supply air missing or not

connected.

Check the supply air. See

section5.4.

–

Incorrect terminal

assignment

Connect+and–

terminals correctly. See

section5.3.

NOTICE

i/p converter does not

need any extra voltage!

Do notconnect24VDC.

Incorrect input signal Connect correct signal.

Read nameplate:

0to20mA or

4to20mA.

Restrictor clogged up.

Clean the restrictor (see

section7.1).

–

Output signal does not

change proportionally

into the input signal.

Poor air quality.

Contact SAMSON's

After-sales Service.

Make sure that the air

quality complies with the

requirements (see

section3.2).

Checktheairlterand

separator installed in the

upstream air reducing

station regularly.

Mechanics stuck (e.g.

due to mechanical

shock).

Contact SAMSON's

After-sales Service.

–

SinteredlterinSUPPLY

and OUTPUT connection

clogged up with dirt.

Clean or exchange

sinteredlter.

–

Tip

Loading...

Loading...