ENGLISH-24

Pipe work

Flushing and air-purging

When lling water, the following start-up procedure should be followed.

1. All system components and pipes must be tested for the presence of leaks.

2. Make-up water assembly or Flushing unit is recommended for installation and service.

3. Before connecting pipes to the hydro unit, Flush water pipes clean to remove

contaminants during 1 hours using a ushing unit or tap water pressure if it is

adequate (at 2 to 3 bar)

4. Fill water into the hydro unit by opening service valves.

5. Purge the air. (Fill with a ushing unit with sucient capacity: avoid aerating the water)

6. Circulate for long enough to ensure that all air has been bled from the complete water

piping system.

After installations, Commissioning should be performed by qualied representatives.

Unless ushing and air-purging works are performed adequately, It might result in

malfunctions.

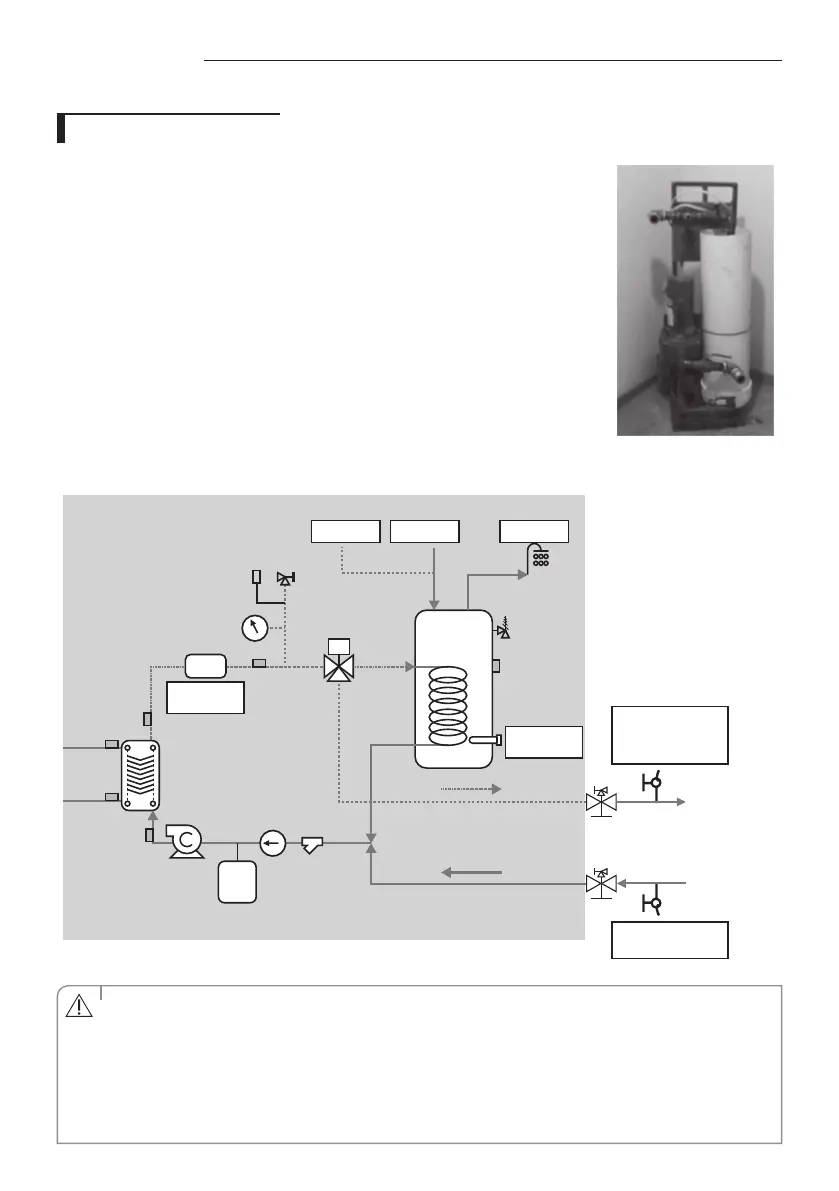

Flushing unit (or purging cart)

3

G3 KIT

3-Way V/V

Backup

heater(2kW)

PWM

Pump

HX_PHE

Expansion Vessel(8L)

Flow

sensor

Pressure

Relief v/v

Air Vent

Manometer

Water in

Water out

Temperature &

pressure relief valve

Service ports for

flushing & purging

(Field supply parts)

Service ports for

flushing & purging

T_tank

Drain(Tundish)

T_w3

T_w2

T_w1

T_eva out

T_eva in

Booster

heater(3kW)

• Check and clean strainer periodically.

• Replace strainer when necessary.

• Its recommended that you ush the system for 4 hours minimum once a per annum.

• Use chemical cleaning agents(Begin with acid , nish with alkali).

• Install Air vents on the top of the system

• Pressure of entering water(over 2.0 bar)

• Water quality must be according to EN directive 98/83 EC.

CAUTION

Loading...

Loading...