2. Alarm causes and working status table.

Circulating pump works

properly

Room temp sensor failure

(constant temp invalid)

Water temp sensor failure

Low flow rate /

water flow alarm

Note: The alarm output port is connected with a set of normally open and normally closed contacts

of the relay inside the machine. The working current should be smaller than 3A while the working

voltage should be smaller than 300V.

VII.

Maintenance

For equipment maintenance, firstly the machine must be stopped and the power must be

cut off. Wait 3 minutes before starting the maintenance process, otherwise there will be a

risk of electric shock. When the ambient temperature is lower than 2°C, the internal water

must be drained when the machine is shut down for a long time.

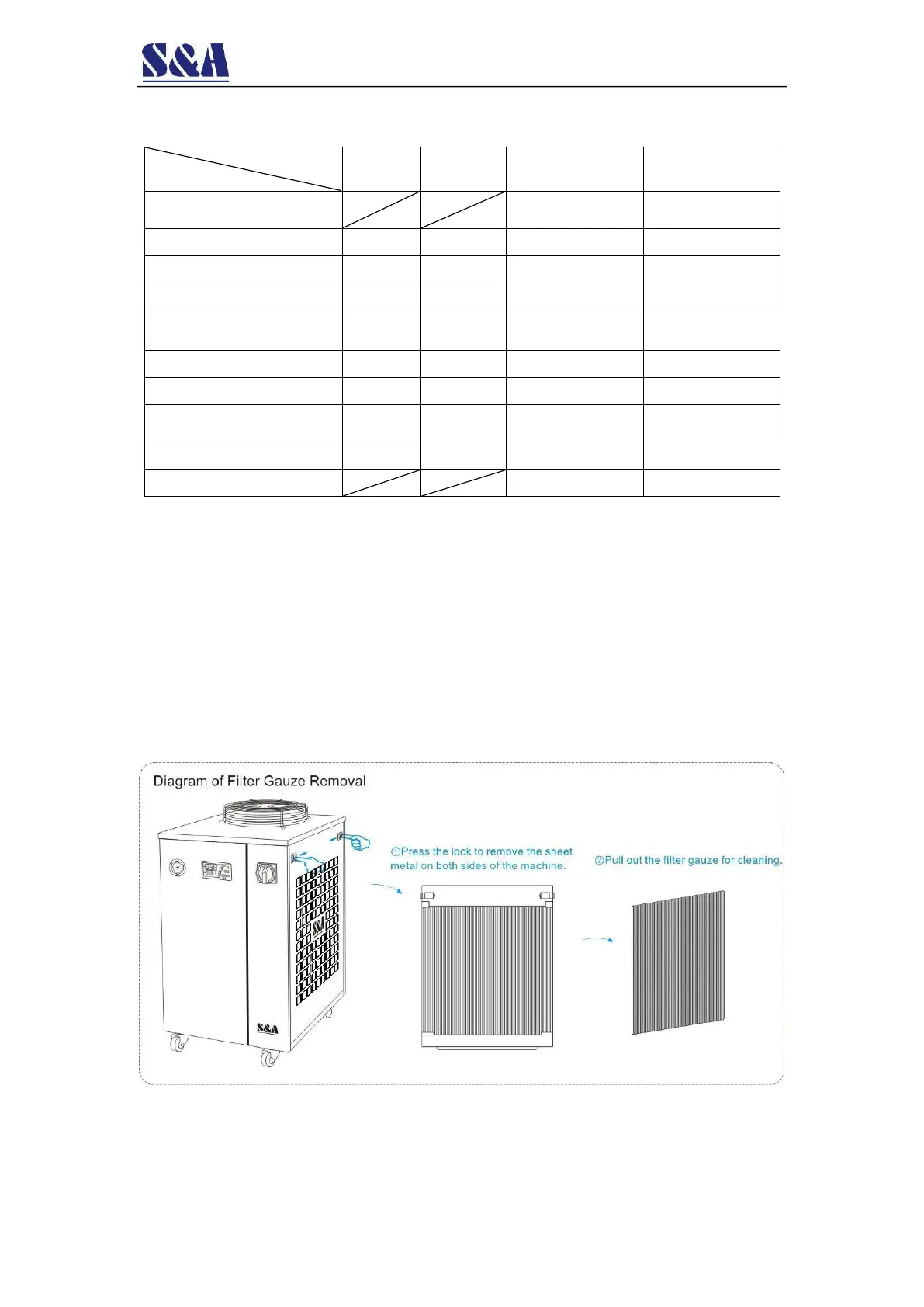

Disassemble the dust filter regularly for cleaning and use a compressed air gun to blow off

the dust accumulated in the condenser. (It is recommended to clean it once a week, and

the chiller should not without the dust filter, except for a quick cleaning process.)

Loading...

Loading...