A2 Automatic Dispenser V3.0 8

and press the piston rod for 2-3 times. Repeat the foregoing steps till there is no colorant drops out.

● Rotate the turntable and empty the canisters in turns with the same method.

● The machine will lift and press the piston rod for recirculation and exhausting the air automatically in every

24 hours.

● Do not lift the piston rod if not necessary

● Please cover the lids promptly to avoid evaporation of colorant.

The machine had been calibrated in the factory. Customers can also recalibrate in 4-7 hours after colorants have

been filled if they need. A scale with minimum accuracy of 0.001g and the colorant density are a must for

recalibration.

Stir for 30 minutes after adding colorants, to remove bubbles.

When no continuous dispensing of colorants, please re-empty air or check if nozzle is blocked.

All the preparation steps are followed, the colorants could be dispensed after 4 hours.

7. Operation

The operations of how to search, dispense and modify the formula are explained in the software using manual.

The operator can operate the machine according to the user manual. But normally, the operator should be got well

trained to operate the dispenser better

The machine should be powered on all the time, there will be no action when emergency button is pressed.

The colorant volume in canister should not be lower than 0.5L.

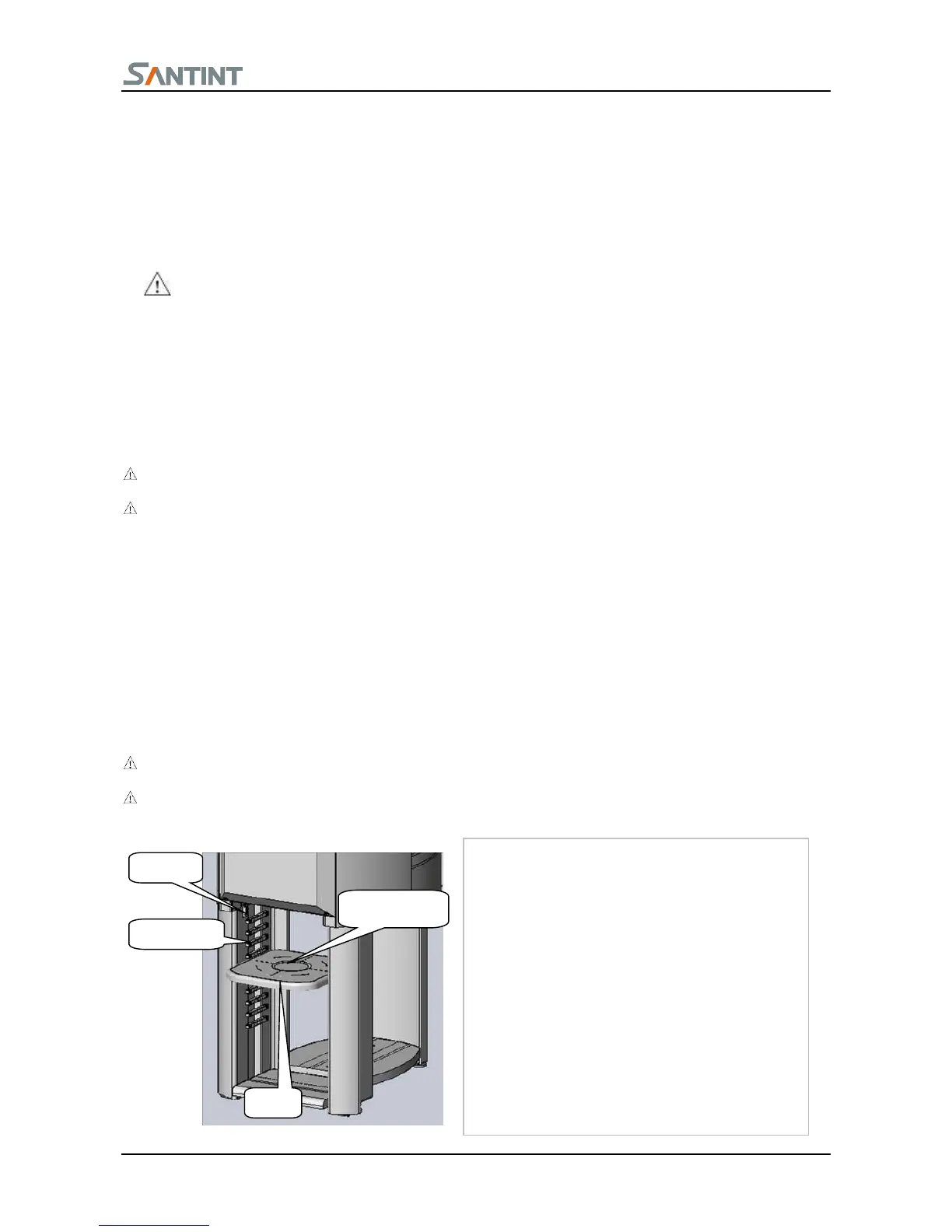

1) Select a lead rail with proper height for the tray.

(The upper rim of the paint can shall be higher

than the sensor.) Insert the tray inside the rail

till the bottom.

2) Open the lid of the base paint can.

3) Locate the base paint can in the center of the

tray.

4) Start dispensing

Loading...

Loading...