Santint

M3 Manual Dispenser V1.0 8

c),do not screw too hard.

B Open canister lid during the process of mixing to observe if the agitator works normally. For any

abnormity, stop mixing and repair the canister.

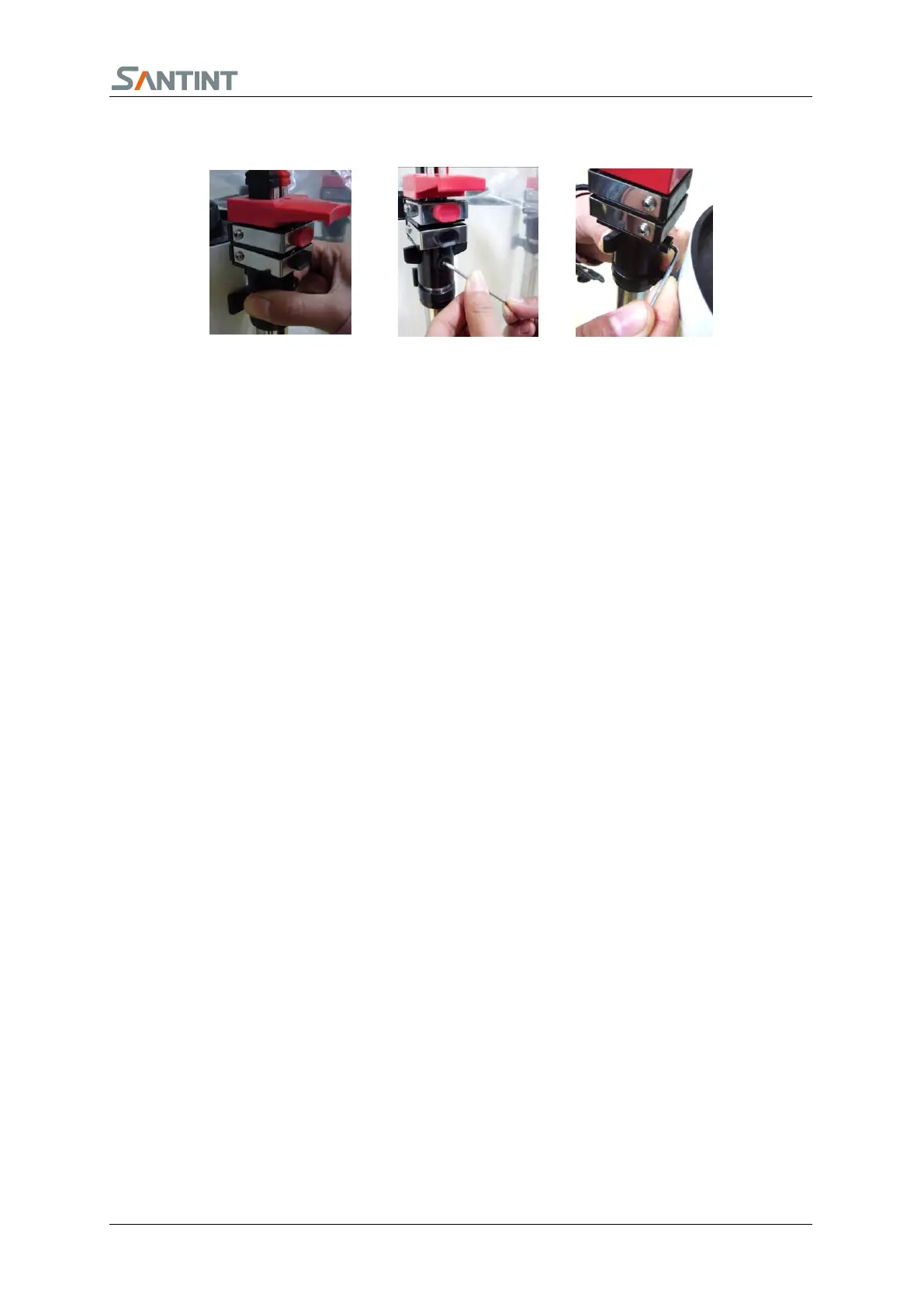

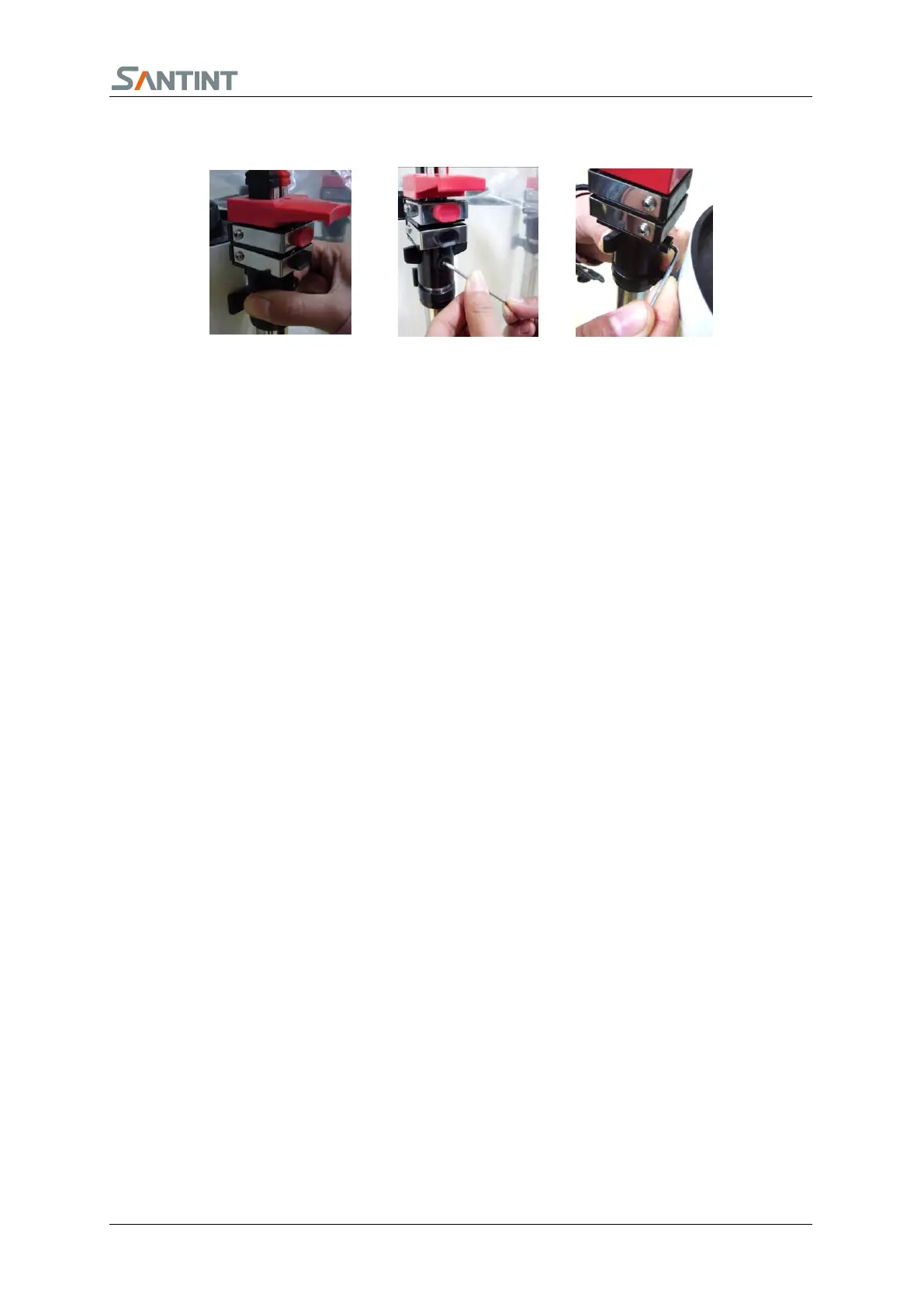

C Clean the nozzle: Rotate the valve handle and pull out the nozzle, Clean the nozzle with cotton

moistened with water or thinner. Then rotate the valve handle once again to reinstall the nozzle.

Notice:

1. After reinstallation of nozzle, dispense out small amount of colorant to fill the nozzle. The

reinstallation must be carried out gently.

2. The manufacturer provides with large-size nozzle; the end user can choose the correct-size nozzle

according to the colorant’s viscosity.

6.4 Yearly Maintenance

After long period of service, the inner wall of the pump or the canister may stick some colorant. This will

make the piston move hardly and cause measurement errors. Small amount of colorant is allowed. But if

too much may cause great difficulties in the movement of the piston and generate measurement errors. In

this case, cleaning must be done to canisters and cylinders.

To clean without dismantling the canisters assembly:

a Remove the canister assembly from the turntable;

b Pour the colorant in the canister into a clean container;

c Clean the canister with warm water to get rid of most of the adhesive colorant;

d Properly dispose the mix of cleaner and colorant according to local environmental regulations;

e Reinstall the canister on the turntable;

Loading...

Loading...