8.3 FAULT FINDING

The Fault Finding chart below will enable operational

faults to be identied and their possible causes rectied.

Any work carried out on the Premier Plus unvented water

heater and its associated controls MUST be carried out by

a competent installer for unvented water heating systems.

In case of doubt contact the Santon Service Department

(see contact details at foot of page 16).

DO NOT TAMPER WITH ANY OF THE

SAFETY VALVES OR CONTROLS SUPPLIED

WITH THE PREMIER PLUS AS THIS WILL

INVALIDATE ANY GUARANTEE

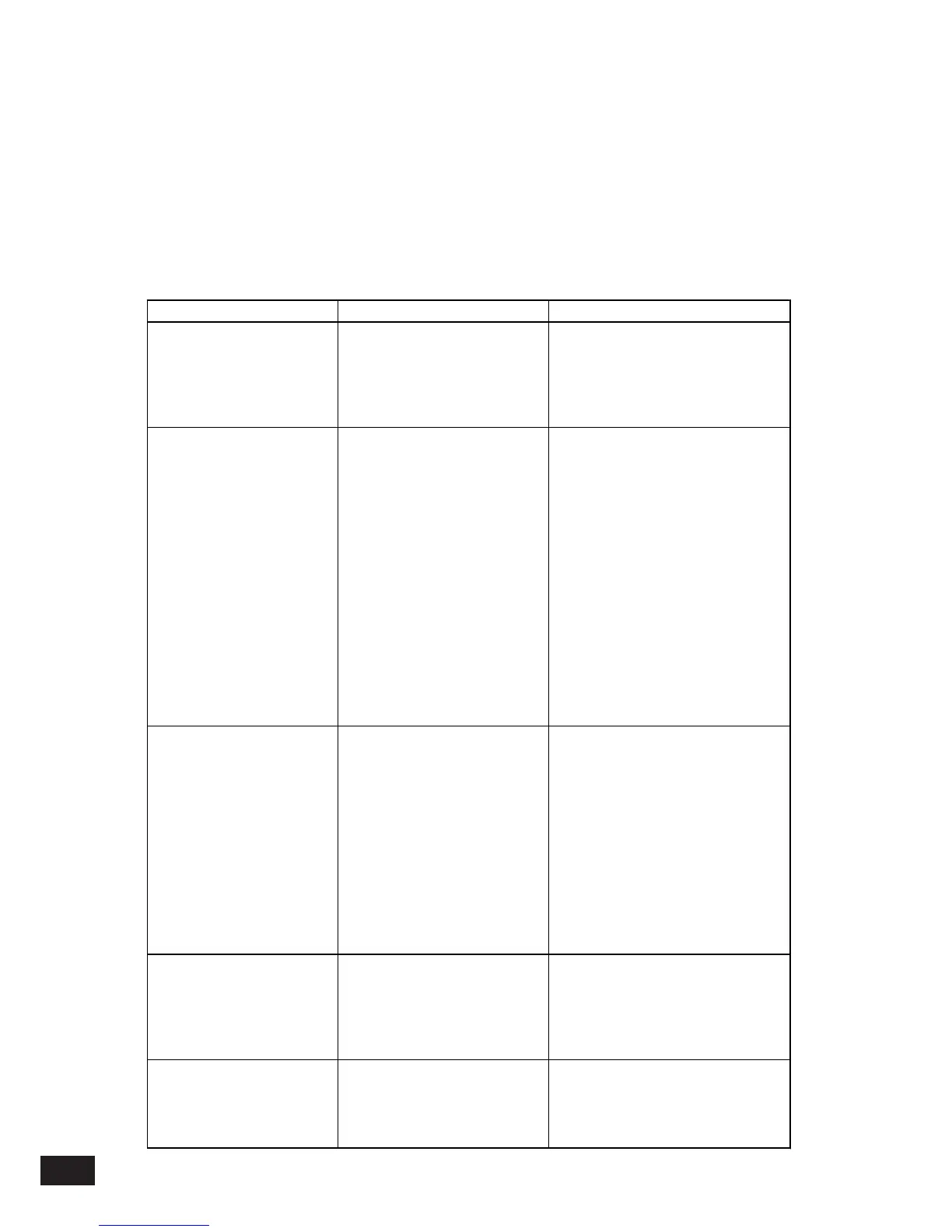

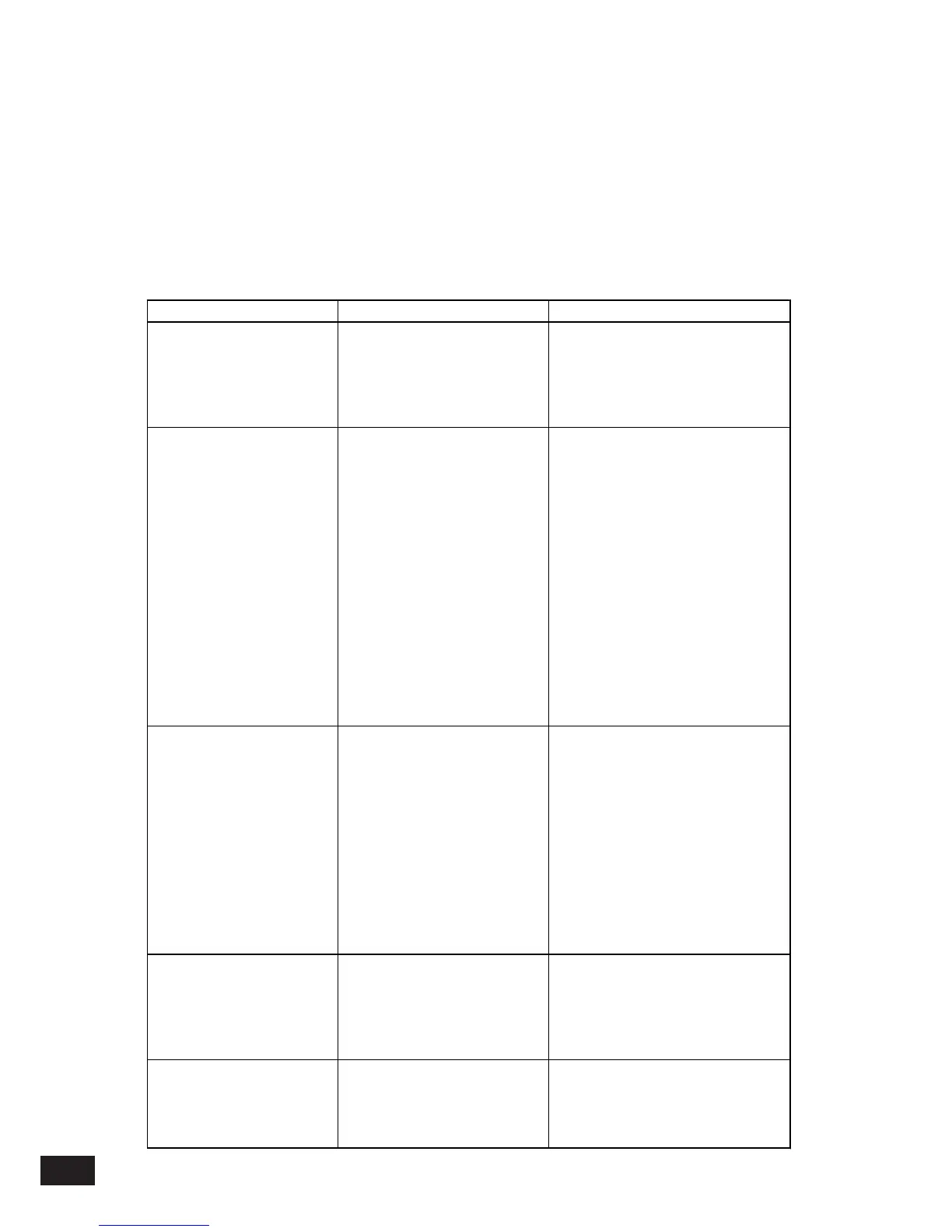

TABLE 5 Fault Finding Chart

WARNING

F A U L T P O SSIB L E C A U S E R E M E D Y

N o ho t w at er flow 1 . M ains s u pp ly off 1. C h ec k and open s t op c o c k

2. S train er bloc k e d 2. Tu rn o ff w a te r s upply .

R em ove s traine r and c lean (s ee

S e c tion 7 .3 )

3. C o ld W ater C o m b ination

V a lve inc o rre c tly fitt ed

3. C h ec k and re fit as requ ired

W ater fro m hot taps is

c old

1. D IR E C T immers ion

he ater not s w itc hed on

1. C h ec k and s w itc h on

2. D IR E C T immers ion

he ater therm al c ut-out has

op erate d

2. C h ec k .

R e s et b y pus hing

button.

3. IN D IR E C T p ro grammer

s et t o C entral H eating only

3. C h ec k . S et to a D om es tic

H ot W ate r pro gramme

4. IN D IR E C T b oiler n ot

w ork ing

4. C h ec k boiler o pe ra tion. If fault

is s us pe c ted c on s ult bo iler

m anufac t urer's in s truc tions

5. IN D IR E C T t he rm al c ut-

ou t has operat ed

5. C h ec k . R es et by pu s hing

button on c ut -out. C h eck

op era tion o f ind ire c t therm os tat

6. IN D IR E C T m oto ris ed

valve not c onnec ted

c orre c tly

6. C h ec k w irin g and/or p lum bing

c on ne c tions to m ot oris ed valve

(s ee F ig. 7)

W ater dis c harg es 1. IN TE R M ITTE N TLY

from E x p an s ion V alve E x pa ns io n V es s e l c ha rge

pre s s u re has reduc ed b elow

3.5bar

1. S ee S e c tion 7.5 fo r re-

c ha rgin g proc edure

2. C O N TIN U A L LY

a. C o ld W ater C o m b ination

V a lve P re s s ure R educ e r no t

w ork ing c orre c tly

a. C h ec k pres s u re from C old

W ater C om bina tion V alve . If

gre at er th an 3.5bar replac e

P ressure R educ e

r c a rt ridge

b. E x pans ion V alve s ea t

da m aged .

b. R e m ove E x pan s ion V a lve

c artridge. Check c ondit ion of

s ea t. If ne c es s ary fit new

E x p ans ion V alve c artridge.

W ater dis c harg es from

T& P R e lief V alve

1. Therm al c ontrol fa ilure

N O TE w a te r will be very hot

1. S w itc h off pow e r t o

imme rs ion h ea te r(s ) a nd s h ut

do w n bo iler. D O N O T turn off

w at er s upply . W hen d isch arge

s to ps c h ec k all t he rm a l

c on trols , re plac e if faulty .

"M ilky" w ate r O x y g e

nated water W ater fro m a pressuris ed

s y s te m rele as es ox y gen

bu bb les w h en flow ing . The

m ilk iness w ill d is appea r aft er a

s ho rt w hile.

Loading...

Loading...