14

2017-12-21 / V1.3

Connectors Series M – Installation and Maintenance Instructions

Cable Assembly and Processing

6.3 Ordering Code for Contacts

Example: SAC-1.00-AG

Contact type

S Pin contact

B Socket contact

Contact surface

AG Silver

AU Gold

Contact diameter

A 1.58 mm

Connection cross

section

B 2.30 mm 0.5 mm

2

C 4.00 mm 0.75 ...1,00 mm

2

1.50 mm

2

Terminal Type 2.50 mm

2

C Crimp 4.00 mm

2

6.00 mm

2

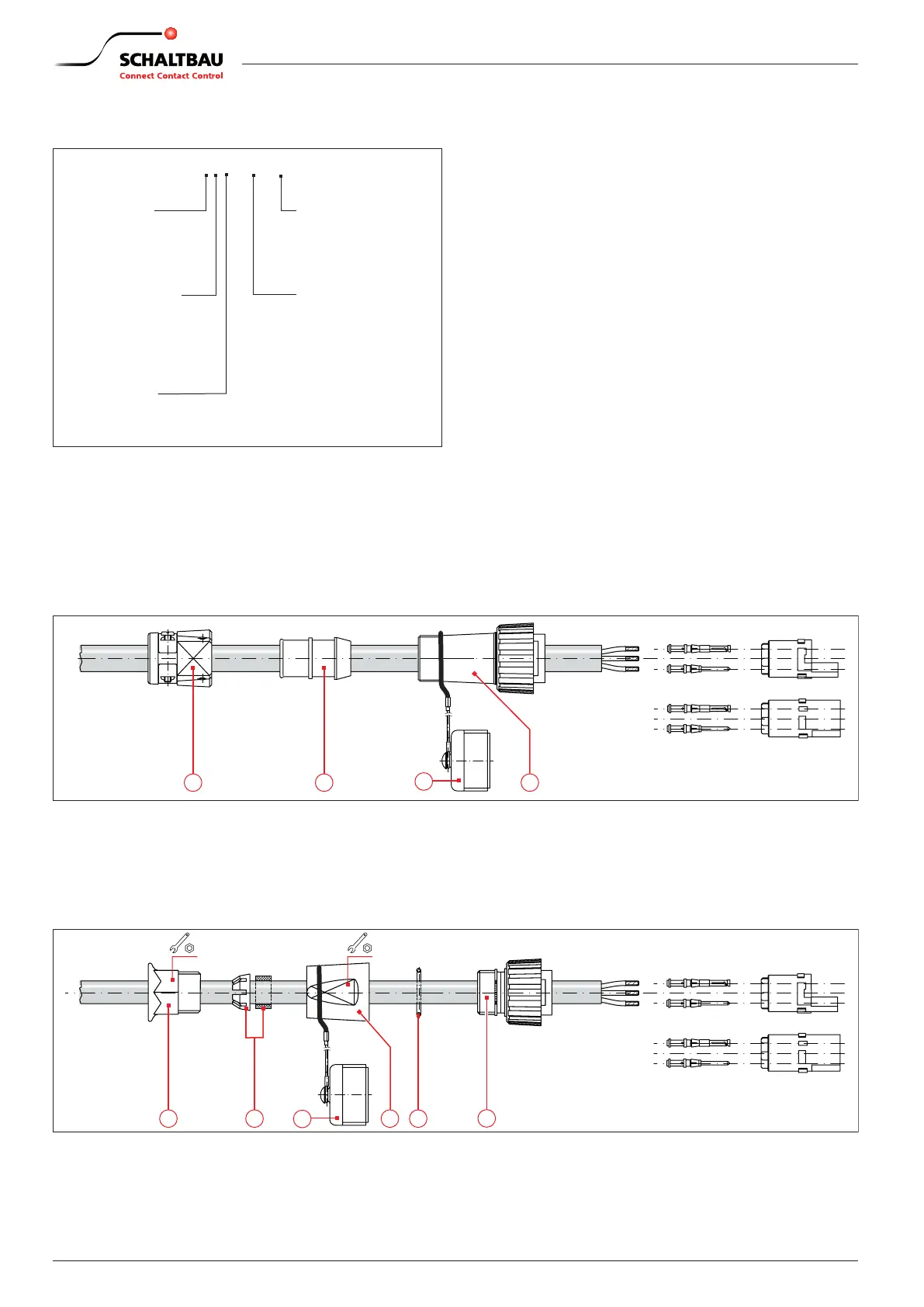

6.4 Threading Parts on Cables

The following illustrations show for some examples how the connector parts have to be threaded on the cables.

Plugs / receptacles for cables

Depending on the application, at rst thread all parts (1 to 6) on the cable.

1

2

4

3

Fig. 6: Example for plug with back shell, strain relief and cable gland (applies also for cable receptacles)

1 Back shell with strain relief and cable gland

2 Cable sleeve with pre-assembled pressure disc

3 Protection cap for plugs or receptacles respectively

4 Plug or receptacle shell respectively

1 52

6

4

3

Fig. 7: Example for plug with thread, back shell and cable gland (applies also for receptacles with thread)

1 Cable gland

2 Strain relief with rubber ring

3 Protection cap for plugs or receptacles respectively

4 Back shell

5 O-ring

6 Plug or receptacle shell respectively

Loading...

Loading...