19

3.5.1 Zero and gain adjustment (cont.)

Gain adjustment:

Requirement:

Zero adjustment carried out.

To carry out gain adjustment:

- Thread the process material through the measuring and guide rollers, following the red

material path symbol on the front of the sensor.

- Hang a weight that corresponds to e.g. 90% of the tension range (pay attention to the

correct unit of measure) from the process material, vertically, as shown in fig. 3.5.1.

(Always use a fresh portion of the material to be measured.)

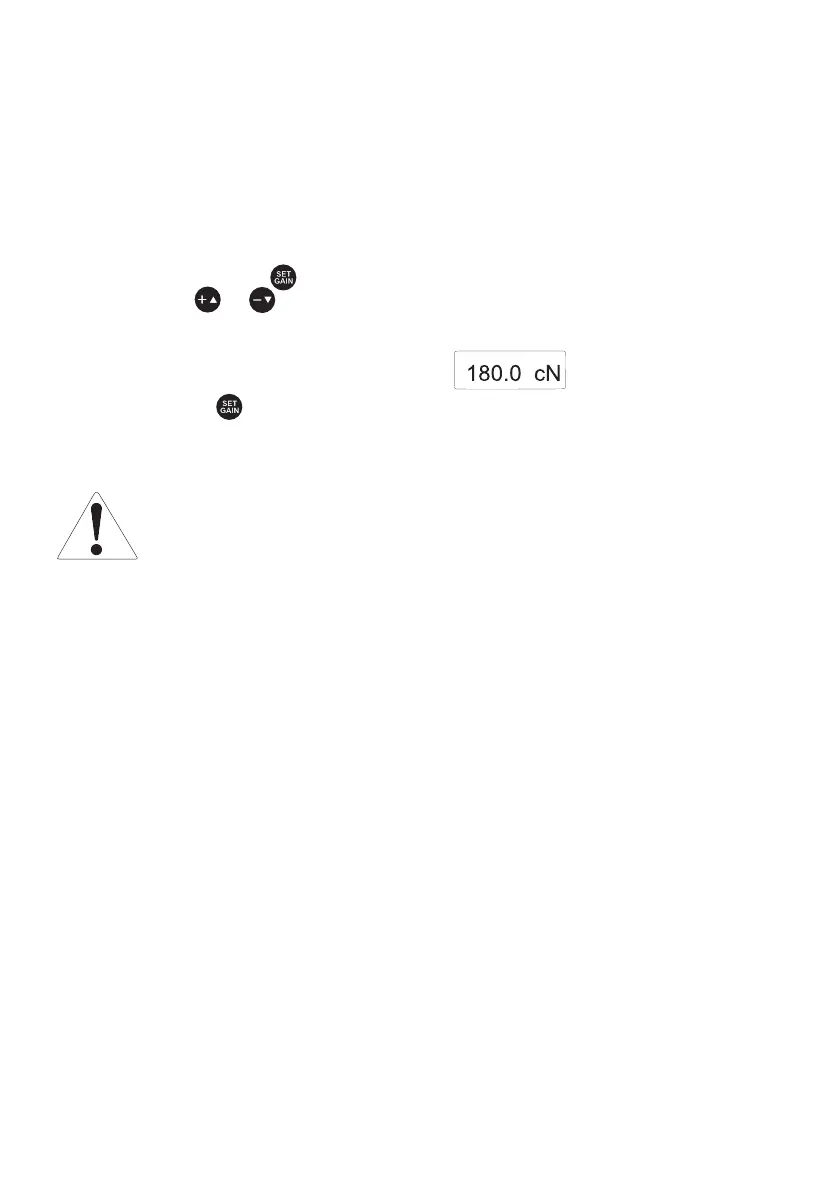

- Press and hold the key.

- Press the or key repeatedly until the tension value on the LCD is equal to the

value of the suspended weight.

For example: Sensor model TS1-200

Weight 180 cN = Display

- Release the key.

The set value is saved to the calibration curve after approx. 20 seconds and the

instrument changes back to measuring mode.

The gain adjustment values are only saved permanently in the SC-PM mem-

ory after approx. 20 seconds. Therefore the unit must not separated directly

from the power supply.

- Check the adjustments with a fresh portion of the process material and repeat the

procedure if necessary.

Loading...

Loading...