18

3.5.1 Zero and gain adjustment

You can save up to three different calibrations.

The instrument is factory-set to material characteristic curve 1.

This is the factory calibration, which should not be overwritten.

Requirements:

- Two weights, one corresponding to 10% and one to 90% of the selected tension range,

must be provided. Pay attention to the selected unit of measure (cN or kg).

- Sensor installed at measuring location.

- Instrument switched on as described in chapter 3.2.1.

- Allow approx. 10 minutes for thermal stabilization of the instrument.

- The desired material characteristic is selected according to chapter 3.3

Zero adjustment:

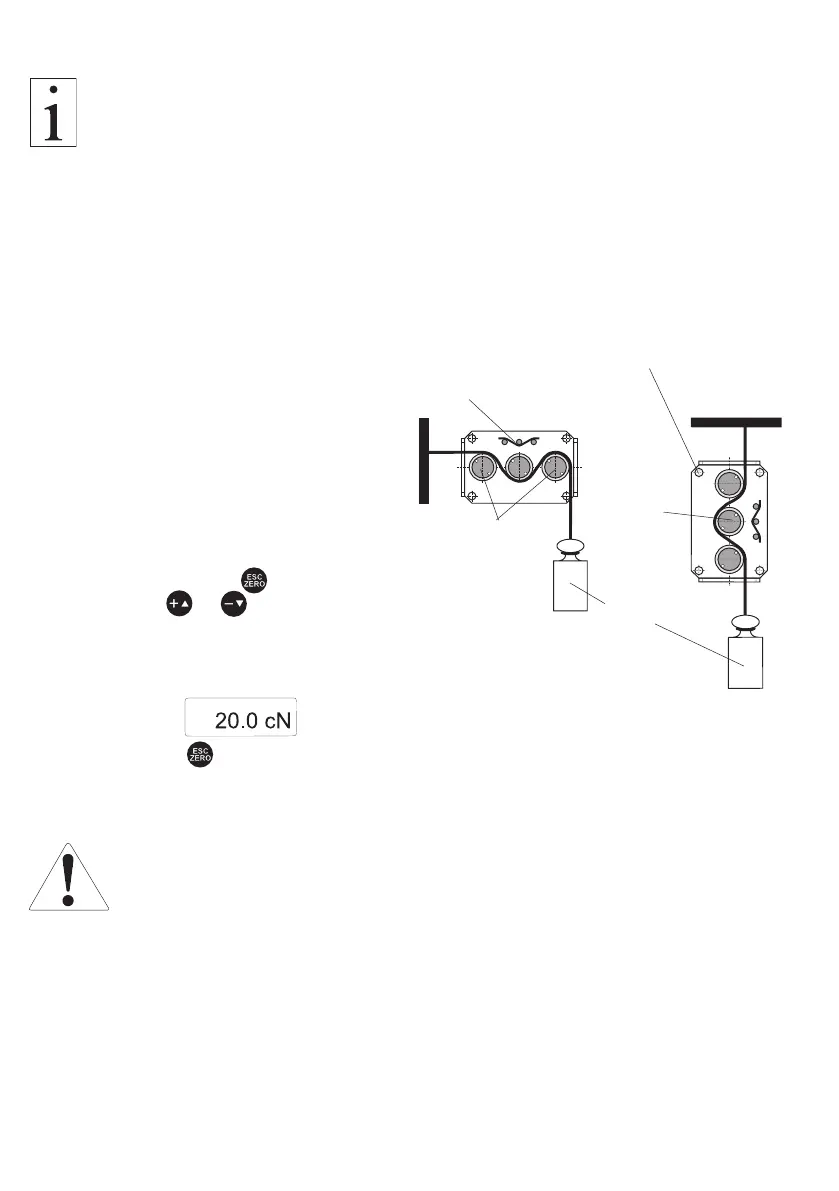

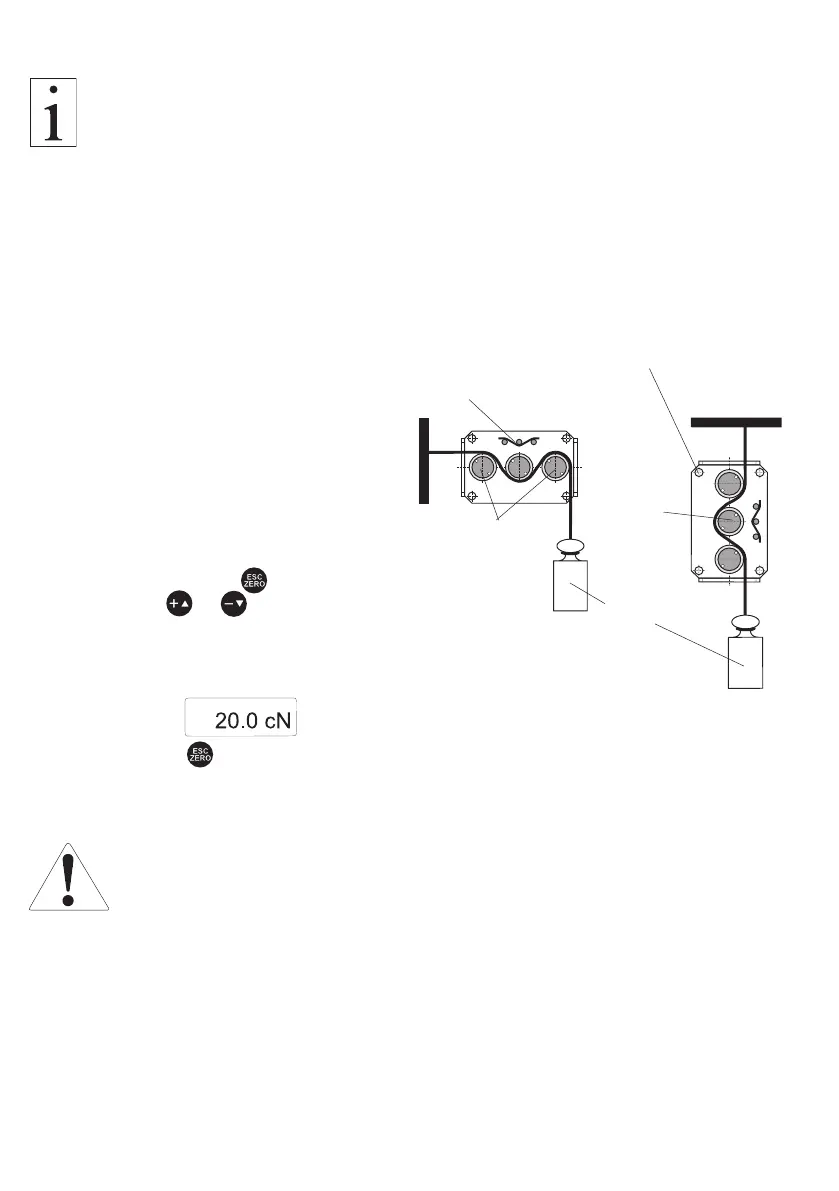

- Thread the process material through the

measuring and guide rollers, following

the red material path symbol on the front

of the sensor.

- Hang a weight that corresponds to e.g.

10% of the tension range (pay attention

to the correct unit of measure) from the

process material, vertically, as shown

in fig. 3.4.1.(Always use a fresh portion

of the material to be measured.)

- Press and hold the key.

- Press the or key repeatedly

until the tension value on the LCD is

equal to the value of the suspended weight.

For example: Sensor model TS1-200

Weight 20 cN =

TFT display

- Release the key.

The set value is saved to the calibration curve after approx. 20 seconds and the

instrument changes back to measuring mode.

Mounting holes 4 x

Weight

fig. 3.4.1

Material path symbol

Measuring

roller

Guide rollers 2x

The zero adjustment values are only saved permanently in the SC-PM mem-

ory after approx. 20 seconds. Therefore the unit must not separated directly

from the power supply.

Loading...

Loading...