Maintenance

03.00 | PWG-S | Assembly and operating manual | en | 389361

23

Maintenance

• Clean all parts thoroughly and check for damage and wear.

• Treat all greased areas with lubricant.

Lubricants/Lubrication points (basic lubrication) [

}

21]

• Oil or grease bare external steel parts.

• Replace all wear parts / seals.

– Position of the wearing parts Assembly drawing [

}

24]

– Seal kit Sealing kit [

}

6]

Assembly

Assembly takes place in the opposite order to disassembly.

Observe the following:

• An assembly bolt is required for the assembly of the PGW-S 80

Assembly with assembly bolt [

}

23].

• Unless otherwise specified, secure all screws and nuts with Loctite

no. 243 and tighten with the appropriate tightening torque.

6.5.1 Assembly with assembly bolt

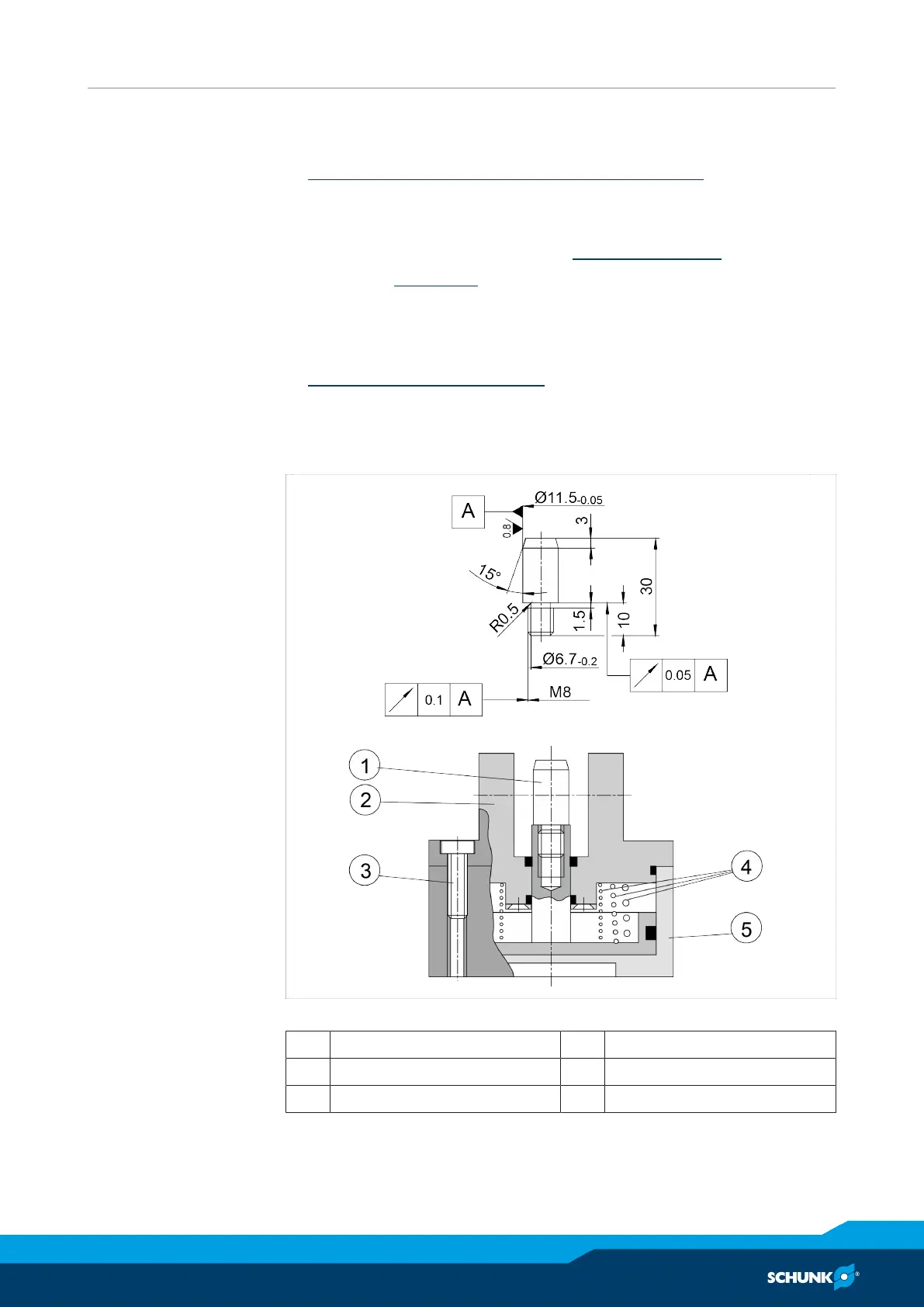

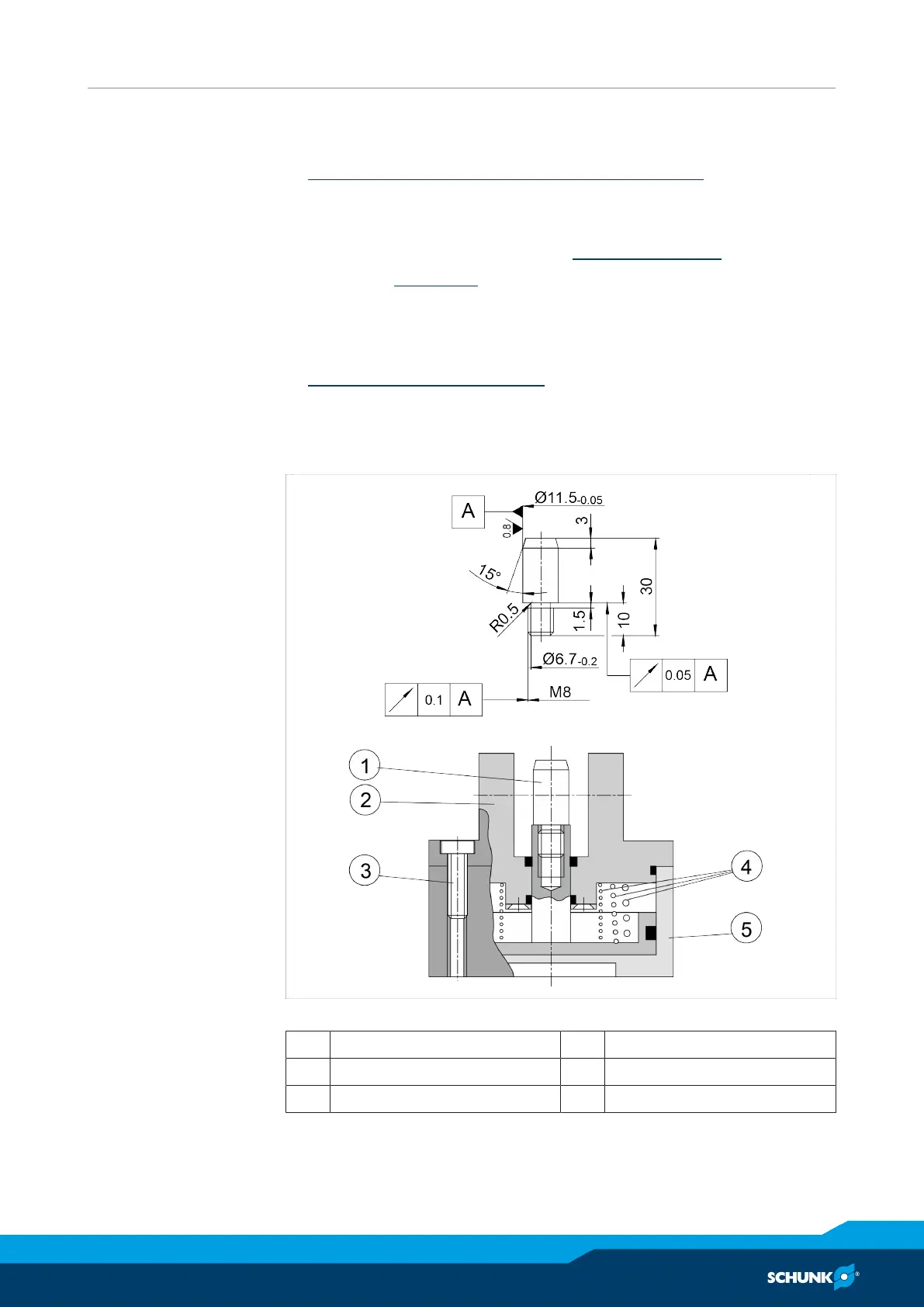

Dimensions and purpose of the assembly bolt

1 Assembly bolt 4 Compression spring

2 Body 5 Cylinder

3 Cylindrical screws

Ø Screw in the assembly bolt (1) by hand.

Ø Press the body (2) onto the cylinder (5).

Ø Screw in the cylindrical screws (3).

Loading...

Loading...