iMAG 4700 INSTRUCTIONS

Seametrics • 253.872.0284 Page 9 seametrics.com

Positioning the Meter

These meters can be installed horizontally, vertically (with

upward ow), or in any radial position. Using a check

valve on the upstream side of the meter, and/or an air

vent (vacuum relief valve) in the same, unobstructed

run of pipe as the meter, is required in any installation

where the meter may be exposed to suction when the

system is not in normal operation. Suction can cause

damage to the liner. Liner damage caused by suction,

without the use of a check valve and/or air vent, may

void the warranty.

Straight Pipe Recommendations. The iMAG requires

straight pipe before and after the meter for best accuracy.

However, the ability of electromagnetic meters to average

the ow across the entire pipe allows for shorter straight

pipe recommendations than most mechanical meters (see

page 7).

Full Pipe Recommendations. To prevent false readings,

this meter is designed to indicate ‘EMPTY PIPE’ if one or

more electrodes is exposed. For highest accuracy, install the

meter so that the pipe will be full when there is ow. If air

bubbles may be present in the pipe or sludge accumulation

is an issue, rotate the meter by one ange hole to position

the control housing at a 45˚ angle (see diagrams on page

8).

Fittings. The iMAG has ANSI 150 lb. drilled anges and

will mate with any other ANSI 150 lb. anges. See table on

page 10 for ange bolt tightening torque specications.

Calibration. The iMAG is factory-calibrated and will not

require any form of eld calibration.

Chemical Injection. When the iMAG is used in a chemical

injection application, the chemical injection point must be

placed downstream of the magmeter OR far enough

upstream for complete mixing to occur before the uid

reaches the meter. When unmixed chemical alternates with

water passing through the meter, the rapid changes in

conductivity may cause sudden spikes and drops in the

meter’s reading, resulting in inaccurate measurement. The

magmeter will re-stabilize, however, with a steady ow of

uid of uniform conductivity.

CAUTION: These ow sensors are not

recommended where installation may

expose the ow sensor to boiler pressure

and temperature. Maximum recommended

operating temperature is 130˚ F.

CAUTION: In chemical injection applications,

install chemical injection point downstream

of magmeter, or far enough upstream to

allow complete mixing of uids.

INSTALLATION

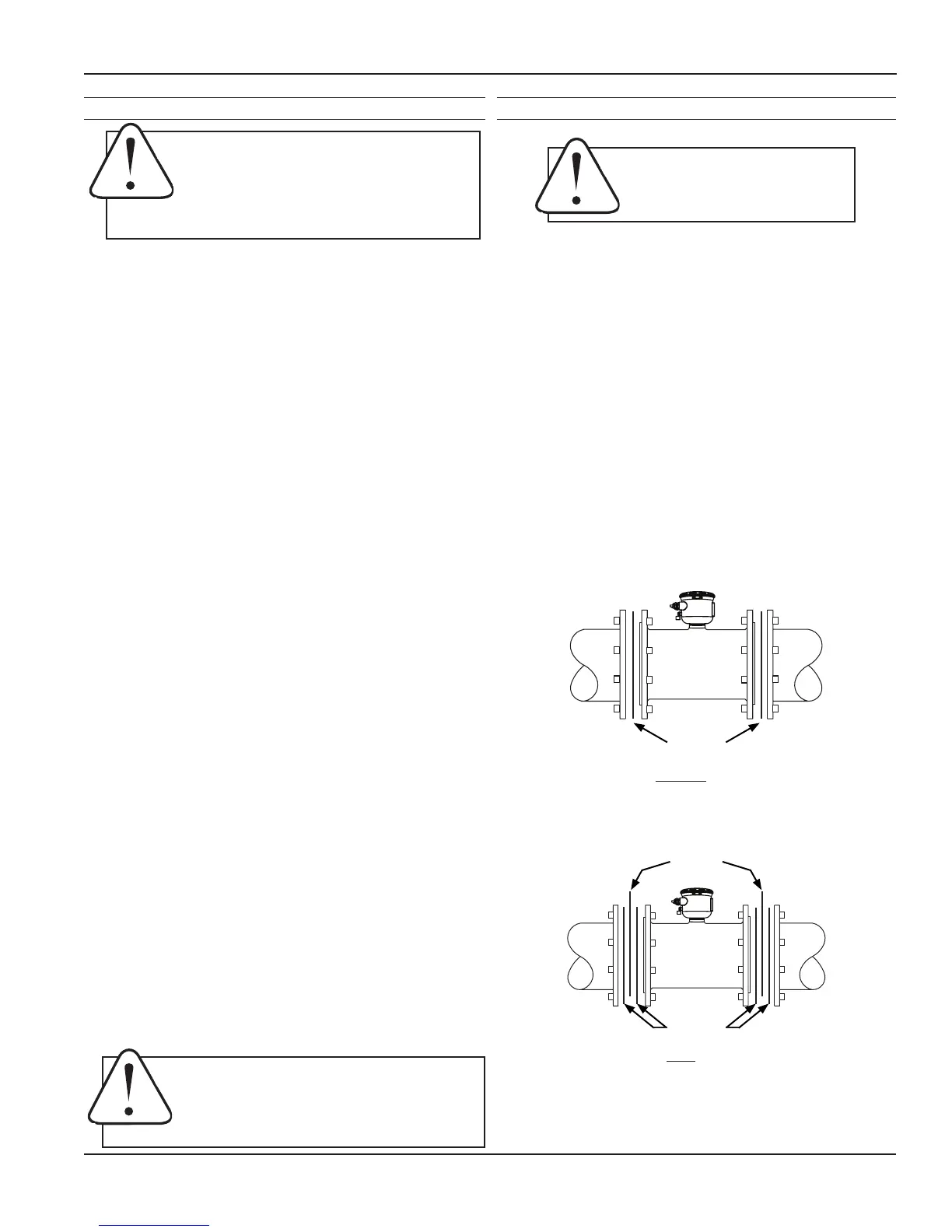

Installing Gaskets

1. Select a suitable full-face gasket.

• Only use at compressible gaskets (either pliable

or hard ber will work).

• Use a material compatible with the uid you will

be using.

• Thickness should be 1/8” - 1/4” (3 - 6 mm),

depending on the atness of the pipe ange

surface.

• Inner diameter must be larger than opening in

ow meter.

2. Be sure all mating surfaces are smooth and free of

debris.

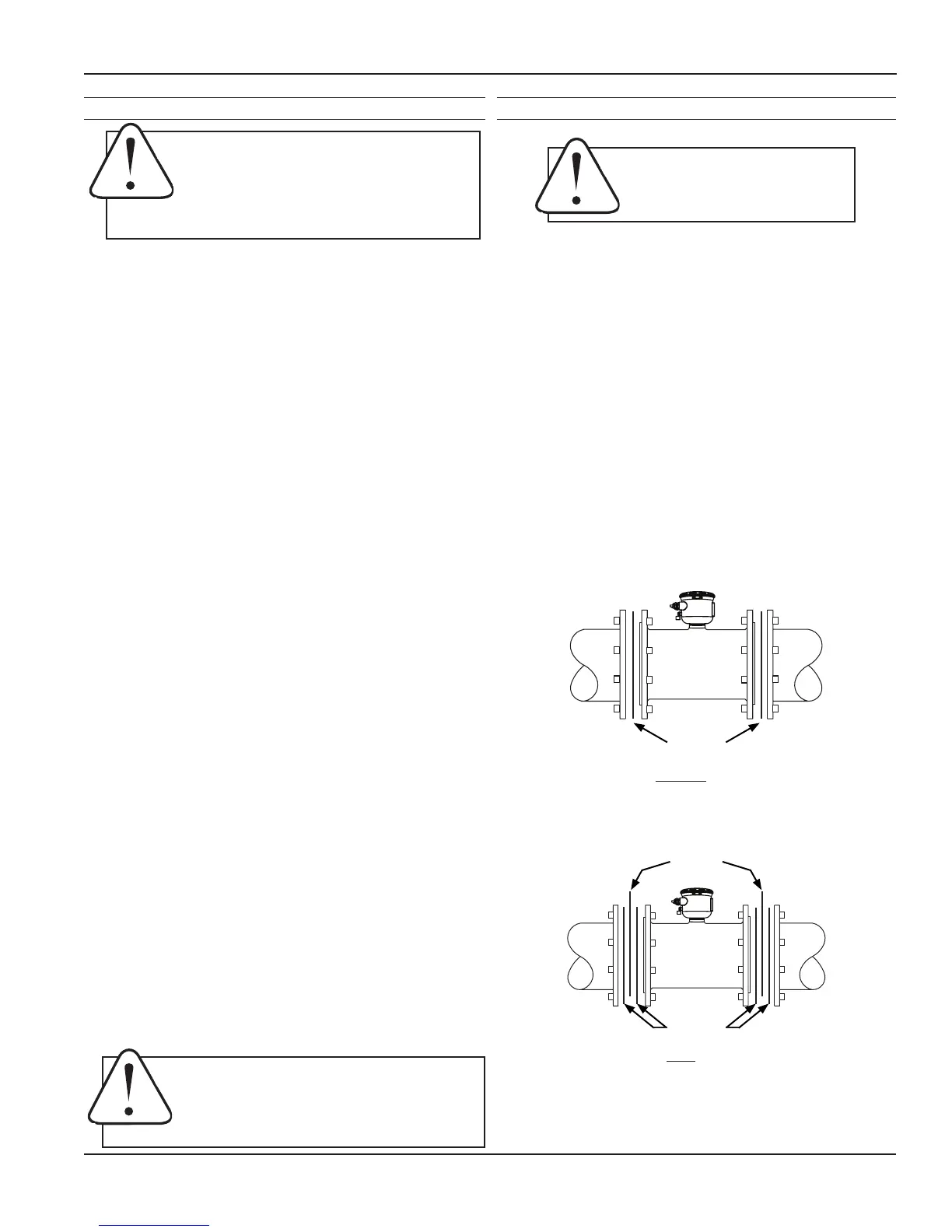

3. Install gaskets on each end of meter as shown in

diagrams below. If using grounding rings, install

one gasket on each side of the grounding ring.

Installation without grounding rings

Installation with grounding rings

GASKETS

Gaskets are required at all

junctions.

Gaskets

Gaskets

Grounding

Rings

Loading...

Loading...