3

Installation Instructions and Owner's Manual

1.6 Maintenance

After FIRST use and every 100 hours or 6 months thereafter

(whichever comes first).

1. Ensure the transom bolts and engine bolts are torqued to their

recommended values.

2. Inspect the Jackplate(s) for damage, cracks, wear and binding.

Inspect the Jackplate brackets, guide rods, actuator shaft and

actuator shaft seal. Check for leaking components.

3. Inspect electrical cables for damage.

DO NOT OPERATE BOAT IF ANY COMPONENT IS NOT IN PROPER

WORKING CONDITION.

Any work being performed with this system MUST be completed

by a qualified mechanic with a working knowledge of the system.

WARNING

1.7 Corrosion Protection

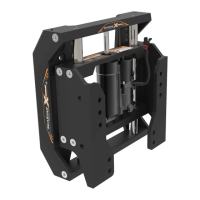

SeaStar Jackplates provide the ability to add an anode to protect

your Jackplate in a machined pocket located on the bottom of the

lower engine bar shown in figure 2 below.

Anode Pocket

Size: 2.92" x 1.40"

Holes: 1/4"–20 UNC (on centers)

Depth: 0.66"

2.00"

1.40"

MAX

2.92" MAX

Figure 2. Anode pocket.

Loading...

Loading...