9

508.366.1488 | www.semshred.com

4. Startup and Operation

Important: Most problems occur during the first hours of operation. These can be eliminated by careful review of

the operating, maintenance and recommended service instructions.

Warning: Use only intended materials in disintegrator or severe jamming may occur. See page 18.

New Operators: It is recommended to give new operators approximately 2 hours for a break in period beginning

with a slow feed rate to familiarize themselves with the device.

4.1 Pre-Start-Up Procedure

• Familiarize yourself with all controls and button locations, as well as this manual.

• Familiarize yourself with the acceptable media for this device.

• Ensure that all guards and covers are in place.

• Ensure that the area is clean.

• Check input area for debris, discarded tools, etc.

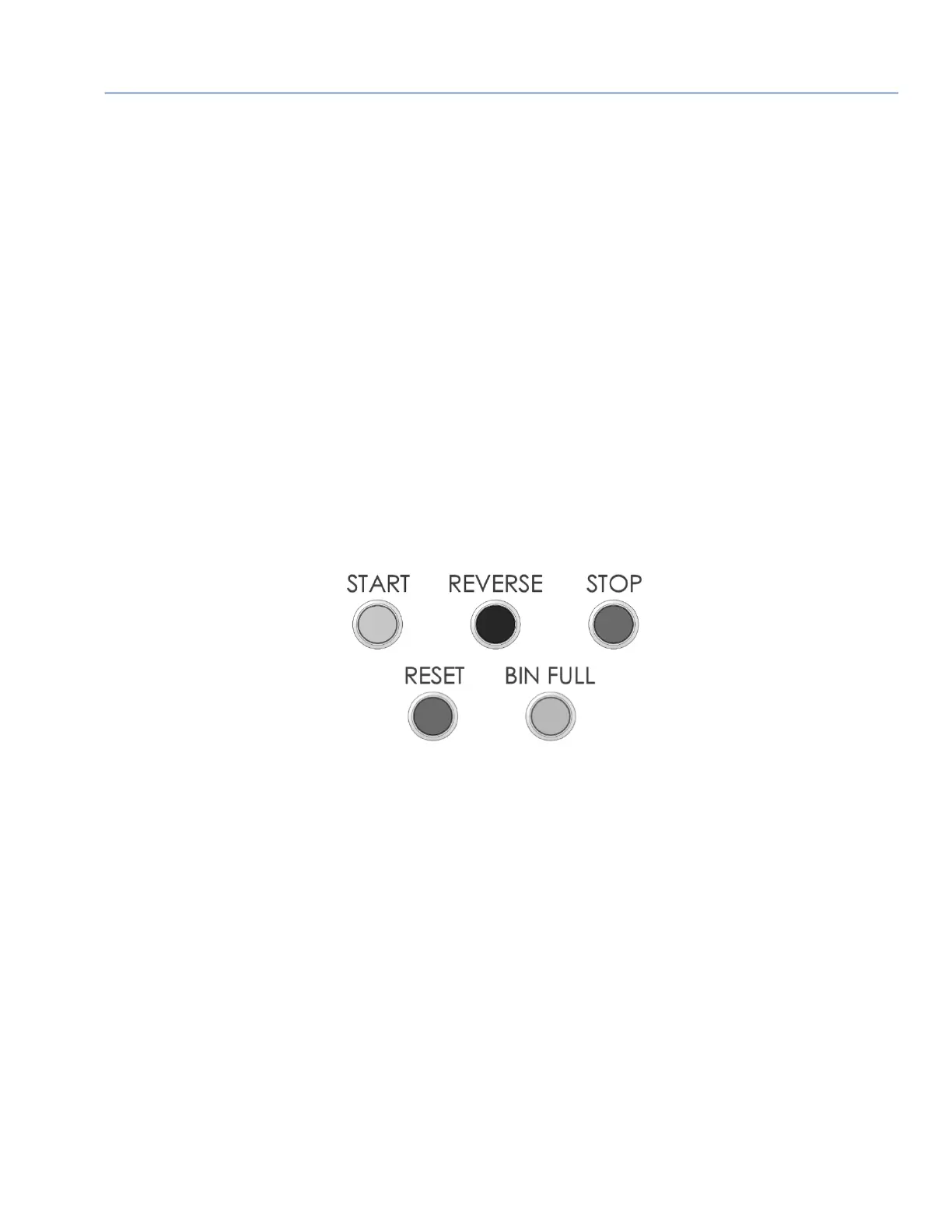

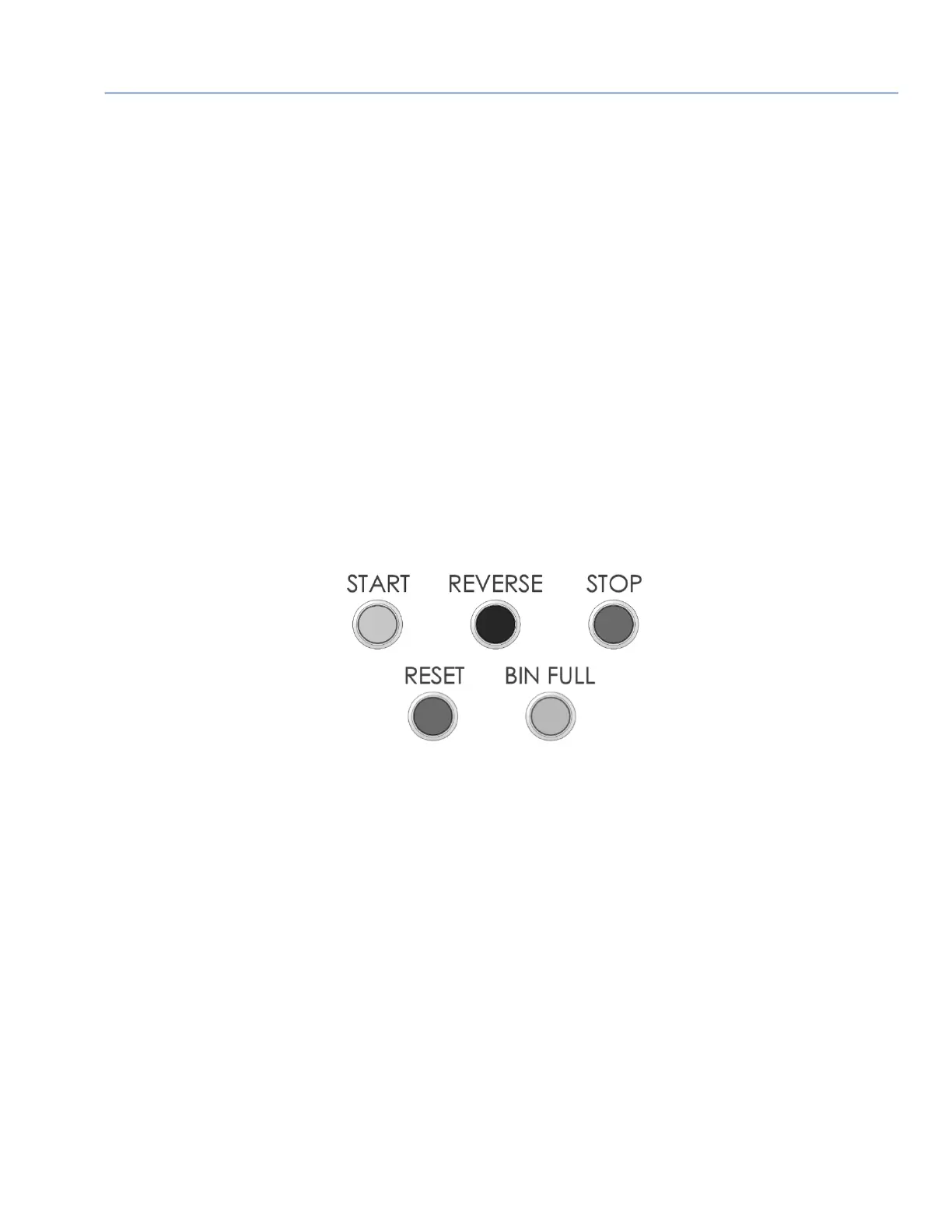

4.2 Controls

• Start: Turns the motors on, one at a time to avoid large current spikes.

• Reverse: Used to manually unjam the stage 1 chamber, will also illuminate during automatic unjamming of stage 1.

• Stop: Stops the stage 1 chamber and begins the timed shutdown for the stage 2 chamber.

• Reset: Used to reset the machine after stage 1 is unjammed.

o Jam Sensor: When the reset light is blinking, check stage 2 for a jam and check belt tension.

o When this light is solid, check the stage 1 chamber for a jam.

o The reset button must be pressed in order for any other button to work on the device, unless it is

completely powered down.

• Bin Full: When this indicator is illuminated, the bin underneath the stage 1 chamber is full and the machine will

begin a timed shutdown and shut off the stage 1 chamber.

Loading...

Loading...